11 Years Manufacturer Nickel Alloy Hastelloy C-4 UNS N06455 Supply to Ukraine

With a positive and progressive attitude to customer's interest, our company continuously improves our product quality to meet the needs of customers and further focuses on safety, reliability, environmental requirements, and innovation of

11 Years Manufacturer Nickel Alloy Hastelloy C-4 UNS N06455 Supply to Ukraine, With the aim of "compete with good quality and develop with creativity" and the service principle of "take customers' demand as orientation", we will earnestly provide qualified products and good service for domestic and international customers.

HY HC-4 Chemical compostion:

|

Alloy |

% |

Ni |

Cr |

Mo |

Fe |

C |

Mn |

Si |

Co |

S |

P |

Ti |

|

C-4 |

Min. |

65 |

14 |

14 |

||||||||

|

Max. |

18 |

17 |

3 |

0.01 |

1 |

0.08 |

2 |

0.01 |

0.025 |

0.7 |

HY HC-4 Physical properties:

|

Density |

8.64 g/cm3 |

|

Melting point |

1350-1400 ℃ |

HY HC-4 Alloy minimum mechanical properties in the room temperature:

|

Alloy |

Tensile strength |

Yield strength |

Elongation |

|

C-4 |

783 |

365 |

55 |

HY HC-4 alloy is a nickel-chromium-molybdenum alloy with outstanding

high-temperature stability as evidenced by high ductility and corrosion resistance even after aging in the 1200 to 1900°F (649 to 1038°C) range. This alloy resists the formation of grain-boundary precipitates in the weld heat-affected zone, thus making it suitable for most chemical process applications in the as-welded condition. C-4 alloy also has excellent resistance to stress-corrosion cracking and to oxidizing atmospheres up to 1900°F (1038°C).

HY HC-4alloy has exceptional resistance to wide variety of chemical process environments. These include hot contaminated mineral acids, solvents, chlorine and chlorine contaminated media (organic and inorganic), dry chlorine, formic and acetic acids, acetic anhydride, and seawater and brine solutions.

HY HC-4alloy can be forged, hot-upset, and impact extruded. Although the

alloy tends to work-harden, it can be successfully deep-drawn, spun, press formed or punched. All of the common methods of welding can be used to weld HASTELLOY C-4 alloy, although the oxy-acetylene and submerged arc processes are not recommended when the fabricated item is intended for use in corrosion service. Special precautions should be taken to avoid excessive heat input.

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

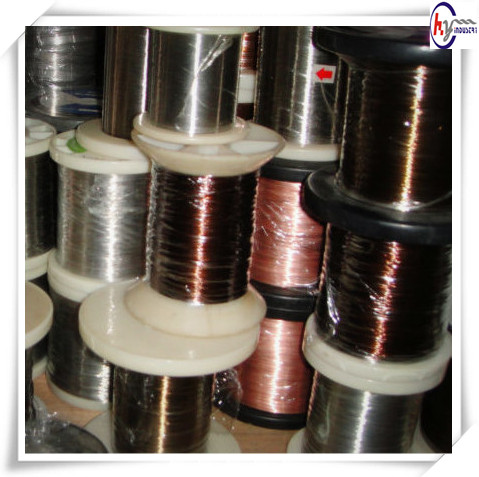

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

Supplier foil、strip、sheet、coil、plate、wire、rod、bar、tube、pipe、flat ribbon、Profiled wire…

BuildingNo.one,Third Industrial District XiTou Village SongGang Town Bao’An District ShenZhen Town GuangDong Province China

Experimentální odlévání monelu na katedře strojírenské technologie při TU v Liberci – Monel je slitina niklu a mědi. Název Monel je registrován jako trademark americké firmy Specific Metals Corporation. Monel vyrobil v roce 1901 Robert Crooks Stanley, slitinu pojmenoval po tehdejším prezidentu firmy Ambrose Monellovi.

Monel vykazuje výborné mechanické vlastnosti a chemickou odolnost v náročném prostředí, např. v dlouhodobém kontaktu se slanou vodou, ale i v chemickém průmyslu. Často bývá využit tam, kde již nedostačují vlastnosti nerezových ocelí.

Monel is a group of nickel alloys, largely composed of nickel (up to sixty seven%) and copper, with tiny quantities of iron, manganese, carbon, and silicon. More powerful than pure nickel, Monel alloys are resistant to corrosion by quite a few agents, like promptly flowing seawater. They can be fabricated quickly by very hot- and chilly-working, machining, and welding.[2]

Monel was made by David H. Browne, main metallurgist for Global Nickel Co. Monel alloy four hundred is a binary alloy of the identical proportions of nickel and copper as is found naturally in the nickel ore from the Sudbury (Ontario) mines and is thus thought of a puritan alloy. Monel was named following business president Ambrose Monell, and patented in 1906.[three] Just one L was dropped, for the reason that loved ones names were being not allowed as trademarks at that time.[one] The title is now a trademark of Specific Metals Corporation.