14 Years Factory wholesale Nickel Alloy Inconel 625 UNS N06625 to Holland Importers

Our team through professional training. Skilled professional knowledge, strong sense of service, to meet the service needs of customers for 14 Years Factory wholesale Nickel Alloy Inconel 625 UNS N06625 to Holland Importers, As we are moving forward, we keep an eye on our ever-expanding product range and make improvement to our services.

HY 625 Material grades and equivalents

Inconel 625/ GB NS336 / UNS N06625/ SEW VDIUV W.Nr.2.4856 NiCr22Mo9Nb / BS NA 12 / AFNOR NC22DNB

HY 625 Chemical composition

|

Alloy |

% |

Ni |

Cr |

Mo |

Nb+N |

Fe |

Al |

Ti |

C |

Mn |

Si |

Cu |

P |

S |

|

625 |

Min. |

58 |

20 |

8 |

3.15 |

|||||||||

|

Max. |

23 |

10 |

4.15 |

5 |

0.4 |

0.4 |

0.1 |

0.5 |

0.5 |

0.5 |

0.015 |

0.015 |

HY 625 Pysical properties

|

Density |

8.4 g/cm³ |

|

Melting point |

1290-1350°C |

HY 625 Alloy m inimum mechanical properties in the room temperature

|

Alloy state |

Tensile strength |

Yield strength |

Elongation A 5 % |

Brinell hardness |

|

625 |

760 |

345 |

30 |

≤220 |

Characteristic as below

1. Excellent corrosion resistance of different kinds of media in both oxidation and reduction environments.

2. Excellent resistance of pitting and crevice corrosion, and won’t happen stress corrosion cracking because of chloride.

3.Excellent resistance of the inorganic acid corrosion performance, such as nitric acid, phosphoric acid, sulfuric acid, hydrochloric acid and the mixture of sulfuric acid and hydrochloric acid.

4. Excellent corrosion resistance of different kinds of inorganic acid mixture performance.

5. Good corrosion resistance of a variety of concentrations of hydrochloric acid when the temperature up to 40°C .

6. Good machining and welding, no weld cracking sensitivity.

7. Have pressure vessel authentication for the wall temperature between -196 ~ 450°C .

8. Apply for the highest standard lever VII of acidic environment by the NACE ( MR-01-75) authorized.

HY 625 Corrosion resistance

625 own a very good corrosion resistance in many media, especially with excellent resistance to pitting, crevice corrosion, intercrystalline corrosion, and erode in oxide, also good resistance to inorganic acid corrosion, such as nitric acid, phosphoric acid, sulfuric acid and hydrochloric acid. 625 can resist the alkali and organic acid corrosion in the oxidation and reduction environment. Effect resists the chloride reduction stress corrosion cracking. Normally no corrosion in the sea-water and industry environments since high corrosion resistance to the sea-water and salting liquid,as well as in high temperature, without sensitivity during welding. 625 have the resistance to oxidation and carbonizing in the static and cycle environments, also hacve the resistance the chlorine corrosion.

HY 625 Application field

Soften annealing low carbon alloy 625 widely used in the chemical process industry, good corrosion resistance and high strength made it an good choice for structural parts. 625 have application in sea-water for local mechanical stress attach.

HY 625 Typical application field as below

1 .The Organic chemical process parts contains chloride, especially in the use of acid chloride catalyst.

2. The digester and bleacherin the use of paper pulp and paper making industry.

3.Absorption tower, re-heater,gas import board, fan, blender, fair water fin, flue and so on for using in flue gas desulfurization system.

4. The equipment and parts in the use of acidic gas environments.

5. Acetic acid and anhydride reaction generator

6. Sulfur acid cooling

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

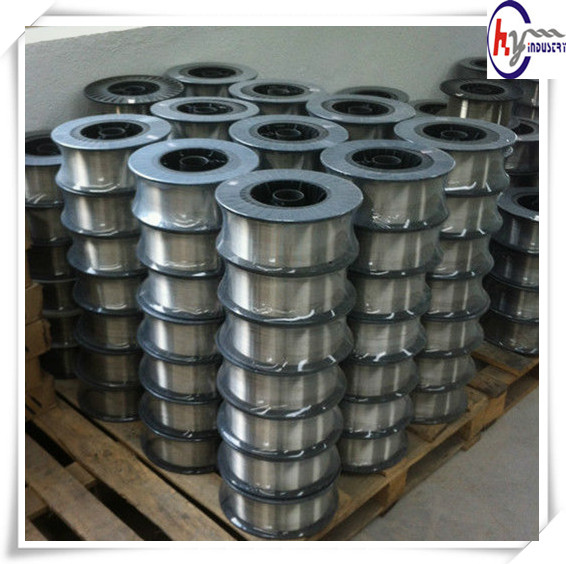

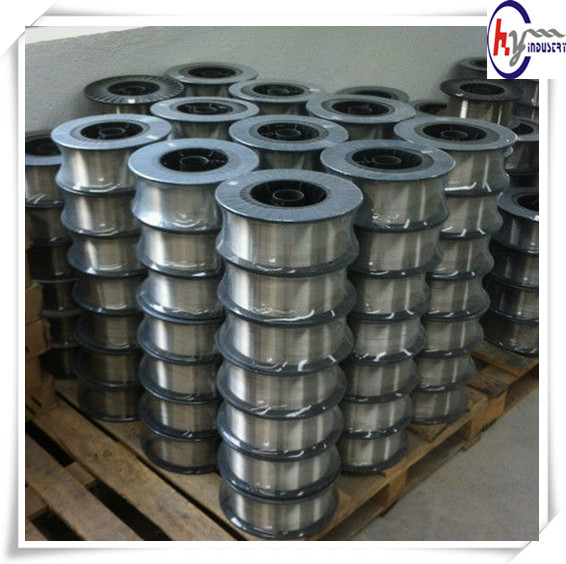

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

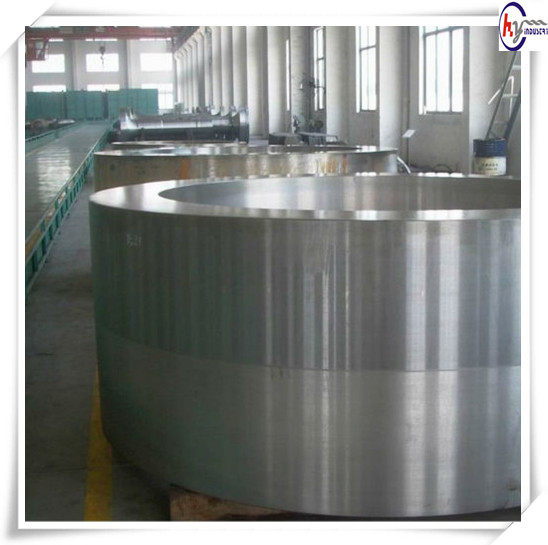

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

A nitinol wire/form memory alloy inchworm that walks across a table employing only warmth. The warmth is supplied by electrical existing heating up the skinny nitinol wire, causing it to return to its remembered form, a compressed coil in this scenario. A V-formed spring returns it to the commencing form.

Guidance RimstarOrg on Patreon https://www.patreon.com/user?u=680159

Subscribe for new films every single week http://www.youtube.com/user/rimstarorg?sub_affirmation=1

Go to the principal channel webpage below https://youtube.com/rimstarorg

See also:

How to Make Nitinol Wire Inchworm (Shape Memory Alloy)

https://www.youtube.com/look at?v=getfzfZJjHM

Nitinol Wire – How to Use it

https://www.youtube.com/look at?v=4Yi4epJ83EE

How a Rocket Performs/Earth to Area Eg SpaceX Falcon 9 and Dragon

https://www.youtube.com/look at?v=L0AMQ6kRNMA

My webpage about this nitinol wire inchworm:

http://rimstar.org/science_electronics_tasks/nitinol_wire_inchworm_form_memory_alloy_handmade.htm

Adhere to at the rear of-the-scenes on:

Twitter https://twitter.com/#!/RimStarz

Google+ https://additionally.google.com/116395125136223897621

Fb https://www.fb.com/rimstarorg

http://rimstar.org

The inspiration came from this one:

https://www.youtube.com/look at?v=DW4WaTmoZ3c

Essence – audio by audionautix.com

http://www.GovLiquidation.com – This 69,560 lbs of Inconel 625 scrap steel has been bought. To look at a current checklist of obtainable scrap steel material, pay a visit to http://bit.ly/jL05Ke currently!

This Inconel was in matrix roll kind and free in pans. This good deal of significant temp alloy scrap steel consisted of Carbon: max .10%, Chromium: min 20% max 23%, Iron: max 5%, Silicon: max .fifty%, Manganese: max .fifty%, Sulfur: max .015%, Phosphorus: max .015%, Molybdenum: min 8% max 10%, Titanium: max .forty%, Nickel: Stability.

This material was positioned in Anniston, AL.

To look at a current checklist of obtainable scrap steel material, pay a visit to http://bit.ly/jL05Ke currently!