14 Years Factory wholesale Titanium alloy 6Al-2Sn-4Zr-2Mo UNS R54620 Export to Afghanistan

Our company since its inception, always regards product quality as enterprise life, continuously improve production technology, improve product quality and continuously strengthen enterprise total quality management, in strict accordance with the national standard ISO 9001:2000 for 14 Years Factory wholesale Titanium alloy 6Al-2Sn-4Zr-2Mo UNS R54620 Export to Afghanistan, We fully welcome customers from all over the world to establish stable and mutually beneficial business relationships, to have a bright future together.

HY Titanium 6-2-4-2 Material grades and equivalents

6Al-2Sn-4Zr-2Mo, 6-2-4-2 Titanium, 6-2-4-2, UNS R54620

Introduction

A near-alpha alloy, primarily used for high strength and toughness, with good creep resistance up to 1000°F. Forging and machining characteristics similar to those of Ti 6Al-4V. Applications include compressor components, hot airframe skin, and engine afterburner structures. The weld ability of Ti 6-2-4-2 is fair, using AMS 4952 weld wire. Several different treatments are available.

Chemistry Composition

|

|

Al |

Sn |

Zr |

Mo |

C |

N |

H |

O |

Si |

Fe |

Y |

Others, |

Others, |

Ti |

|

MIN |

5.5 |

1.8 |

3.6 |

1.8 |

- |

- |

- |

- |

0.06 |

- |

- |

- |

- |

- |

|

MAX |

6.5 |

2.2 |

4.4 |

2.2 |

0.05 |

0.05 |

0.015 |

0.12 |

0.1 |

0.25 |

0.005 |

0.1 |

0.3 |

Balance |

Features

- Machinability similar to austenitic stainless steels

- Easily welded if proper precautions are taken to prevent oxygen, nitrogen and hydrogen contaminations

- Long term stability for temperatures up to 800°F

Applications

- Compressor discs, blades

- Airframe structure, skin

- Engine afterburner components

- Hush kits

Physical Properties

Density: 0.160 lb/in3

Beta Transus: 1825±25°F

Thermal Conductivity: 4.00 Btu • hr/ft2 • hr°F

Coefficient of Thermal Expansion: 32-212°F 4.3 x10-6 in/in°F

Modulus of Elasticity: 16.5×106 psi

Mechanical Properties

Minimum Tensile Properties, AMS 4919, Duplex Annealed

|

Thickness, in |

0.025 ≤ 0.062 |

> 0.062 ≤ 1.000 |

> 1.000 ≤ 3.000 |

|

Tensile Strength, ksi |

135,000 |

135,000 |

135,000 |

|

0.2% offset Yield Strength, ksi |

125,000 |

125,000 |

125,000 |

|

Elongation, % |

8 |

10 |

10 |

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

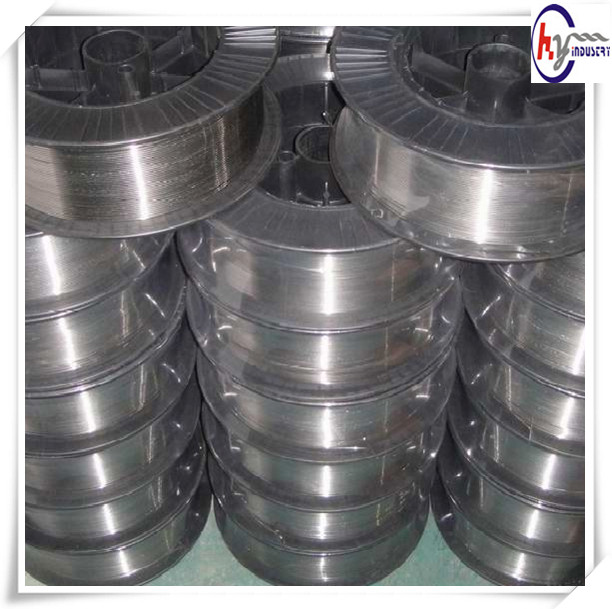

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

I am earning my own wedding day band from Inconel X-750 just to be diverse. The material is a agony to do the job with thanks to the superior nickel/chromium articles. The lathe is a LeBlond “dual generate” with an Aloris-copy device article. I built an adapter for the one.25″ boring bar socket to sleeve it down to a 5/8″ side-lock drill shank. I utilised an indicator to sweep the device holder, inserting it instantly on center. The drill is a Seco CrownLoc As well as with .625″ tip, running at around 80sfm, hand feed with plenty of stress, and drenched in reducing oil (not demonstrated in pic). Chips had been astonishingly limited of course, I had to withdrawal the device numerous moments to eliminate chips, due to the fact they weren’t becoming flushed by coolant.

Supplier foil、strip、sheet、coil、plate、wire、rod、bar、tube、pipe、flat ribbon、Profiled wire…

BuildingNo.1,Third Industrial District XiTou Village SongGang City Bao’An District ShenZhen Metropolis GuangDong Province China