15 Years Manufacturer Cobalt Alloy Waspaloy Alloy UNS N07001 Wholesale to Gambia

We believe in: Innovation is our soul and spirit. Quality is our life. Customer need is our God for 15 Years Manufacturer Cobalt Alloy Waspaloy Alloy UNS N07001 Wholesale to Gambia, sincerely look forward to serving you in the near future. You are sincerely welcome to visit our company to talk business face to face with each other and establish long-term co-operation with us!

HY Waspaloy Material grades and equivalents: W.NR 2.4654; UNS N07001; GH4738

Introduction:

HY Waspaloy Alloy is a nickelbase, age hardenable super alloy with excellent high temperature strength and good corrosion resistance, notably to oxidation, at service temperatures up to 1200°F (650°C) for critical rotating applications, and

up to 1600°F (870°C) for other, less demanding, applications. The alloy’s high-temperature strength is derived from its solid solution strengthening elements, molybdenum, cobalt and chromium, and its age hardening elements, aluminum and titanium. Its strength and stability ranges are higher than those typically available for alloy 718.

HY Waspaloy Chemical composition:

| Alloy | % | Ni | Cu | Al | Zr | B | Cr | Mo | Fe | Co | C | Mn | Si | Ti | P | S |

| HY Waspaloy | Min. | Balance | 1.20 | 0.02 | 0.003 | 18.00 | 3.5 | 12.0 | 0.02 | 2.75 | ||||||

| Max. | 0.5 | 1.60 | 0.12 | 0.01 | 21.00 | 5.0 | 2.0 | 15.0 | 0.1 | 1.0 | 0.75 | 3.25 | 0.03 | 0.03 |

HY Waspaloy Physical properties:

| Density | 8.19 g/cm3 |

| Melting point | 1330℃-1360 ℃ |

HY Waspaloy Applications Fileds:

HY Waspaloy is used for gas turbine engine components that call for considerable strengthand corrosion resistance at high operating temperatures. Current and potential applications include compressor and rotor discs, shafts, spacers, seals, rings and casings, fasteners and other miscellaneous engine hardware, airframe assemblies and missile systems.

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

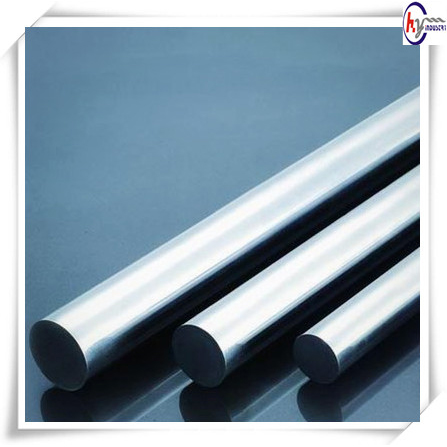

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

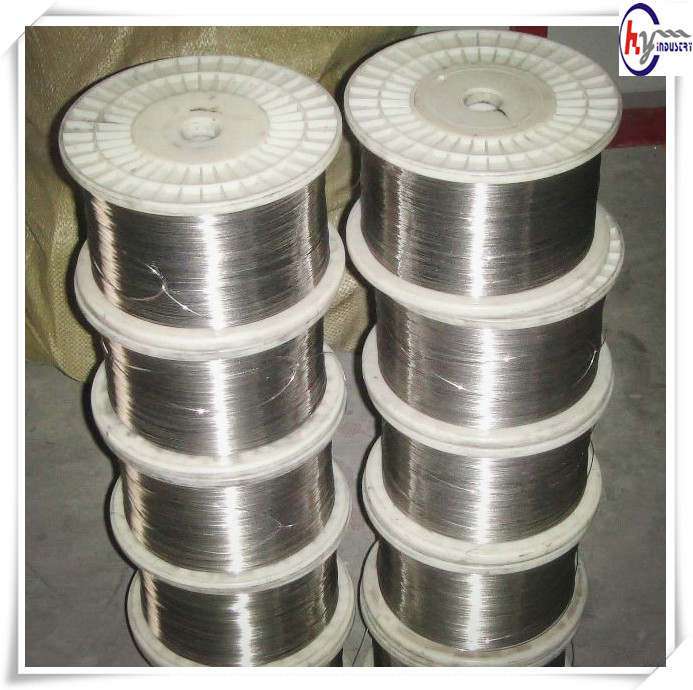

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

Substantial Temp Nickel Centered & Tremendous Alloys – Mechanical Homes Inconel Round Bar, Plate Sheet Offer – Inconel is designed of Mostly Nickel and a number of other aspects. The origin coming from Supernovas. Inconel is a Tremendous Alloy and Michlin Metals sells Inconel Round Bar, Hex Bar, Flat Bar, Plate, Sheet, Tube and Pipe.

Movie da parte di Costanzo Perico