17 Years manufacturer Nickel Alloy Monel 400 UNS N04400 for Sri Lanka Factory

Our team through professional training. Skilled professional knowledge, strong sense of service, to meet the service needs of customers for 17 Years manufacturer Nickel Alloy Monel 400 UNS N04400 for Sri Lanka Factory, We sincerely welcome domestic and foreign merchants who calls, letters asking, or to plants to negotiate, we will offer you quality products and the most enthusiastic service,We look forward to your visit and your cooperation.

HY M400 Material grades and equivalents

Nonel 400/ Alloy400 /UNS N04400 / SEW VDIUV W.Nr.2.4360 NiCu30Fe /BS NA 12 / AFNOR Nu 30

HY M400 Chemical composition

| Alloy |

% |

Ni |

Cu |

Fe |

C |

Mn |

Si |

S |

|

HY M400 |

Min. |

63 |

28 |

|||||

|

Max. |

34 |

2.5 |

0.3 |

2 |

0.5 |

0.024 |

HY M400 Physical properties

| Density |

8.83 g/cm³ |

|

Melting point |

1300-1390 ℃ |

HY M400 Alloy minimum mechanical properties in the room temperature

| Alloy state |

Tensile strength |

Yield strength |

Elongation |

|

HY M400 |

480 |

170 |

35 |

Characteristic as below:

HY M400 is an extremely combination property that use for largest amount and most widely corrosion resistance alloy. This alloy in the hydrofluoric acid and fluoride gas medium with excellent corrosion resistance, as well as to the hot concentrated alkali. At the same time, is also corrosion resistant to neutral solution, sea water, air, organic compounds. An important feature of this is generally do not generate a stress corrosion cracking, good cutting performance.

HY M400 Metallurgical structure

HY M400 alloy is high-intensity single-phase solid solution.

HY M400 Corrosion resistance

HY M400 alloy in the fluoride gas, hydrochloric acid, sulfuric acid, hydrofluoric acid and their derivatives have a very good corrosion resistance property, and possess better corrosion resistance more than the copper alloy in the sea water. Acid medium: HY M400have corrosion resistance in less than 85% consistency of sulfuric acid. HY M400is an important material that resistant to hydrofluoric acid. Water corrosion: HY M400 alloy in most corrosion cases of water, not only excellent corrosion resistance, but also less pitting, stress corrosion, the corrosion rate less than 0.025mm / a. High temperature corrosion: HY M400 for the work of the highest temperature at about 600 ℃ in general in the air, in the high temperature steam, the corrosion rate less than 0.026mm / a. Ammonia: HY M400 can be resistant to an hydrous ammonia and aminate conditions corrosion below 585 ℃ due to the high nickel.

HY M400 Application field:

HY M400 alloy is a multi-purpose material in many industrial applications:

1. Seamless water pipe in the power factory

2. Sea-water exchanger and evaporator

3. Sulfuric acid and hydrochloric acid environment

4. Crude distillation

5. Sea-water in the use of equipment and propeller shaft

6. Nuclear industry and used in the manufacture of uranium enrichment isotope separation equipment

7. Manufacturing hydrochloric acid equipment used in the production of pump and valve

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

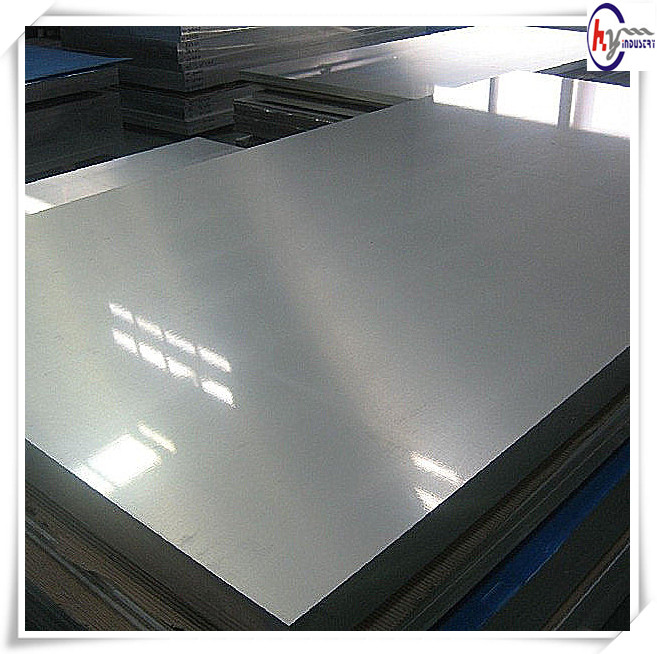

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

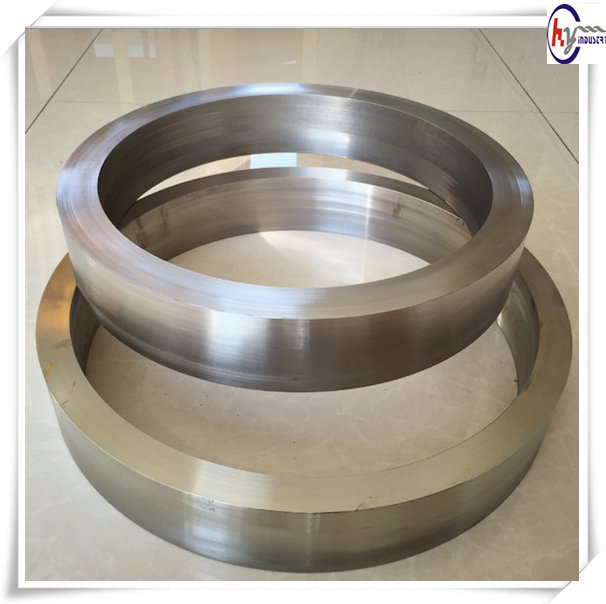

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

» Metal Tubes India is a GOVT. OF INDIA Acknowledged STAR EXPORT Dwelling & PED Accredited Maker

» Metal Tubes India is winner of All India Award for export excellence for 6 Consecutive Many years

» Metal Tubes India is an ISO 9001,ISO 14001,OHSAS 18001 Accredited company, our international CRISIL Ranking is SE 2B

» Metal Tubes India is European Force Machines Directive PED-97/23/EC qualified company

Ni 72., Cr fifteen.5, Fe 8. Mn 1. C .fifteen Cu .5 Si .5 S .015

Significant Efficiency Alloys stocks and produces this grade in the adhering to forms: Bar, wire, sheet, plate, coil, fasteners and forgings. Ask for quote on this grade.

Alloy 600 is a nickel-chromium alloy built for use from cryogenic to elevated temperatures in the selection of 2000 deg F(1093 deg C). The superior nickel material of the alloy allows it to retain substantial resistance less than lessening conditions and makes it resistant to corrosion by a range of natural and inorganic compounds. The nickel material gives it exceptional resistance to chloride-ion pressure-corrosion cracking and also offers exceptional resistance to alkaline options.

Inconel 600 Tube

ASME SB-163 ASME SB-516 ASME SB751 AMS 5580

UNS N06600 also offered in numerous forms like cap, elbow, erw pipes, fasteners, fittings, flange, plate, reducer, spherical bar, seamless pipes, sheet, tee and tube at industrial charge.

+ for extra info & specification about Inconel 600 remember to check out

http://www.steeltubesindia.internet/

Visit my site for additional Recommendations, Films, Do it yourself assignments and additional:

http://www.mjlorton.com/

—————————–Click “Display additional”—————————————

A information on making use of the correct applications to crimp connectors, strip wire and implement warmth shrink.

You should guidance my information generation by making use of my Amazon Retail store:

http://astore.amazon.com/m0711-twenty

Purchase these applications and connectors below: http://astore.amazon.com/m0711-twenty?node=ten&site=one

——————— Click “Display additional” ——————————-

My site and forum:- http://www.mjlorton.com

Donations and contributions:- http://www.mjlorton.com

My techie channel MJLorton – Solar Power and Digital Measurement Products – http://www.youtube.com/MJLorton

My Techie Amazon Retail store: http://astore.amazon.com/m0711-twenty

My other channel VBlogMag – For nearly any matter beneath the sun! – http://www.youtube.com/VBlogMag

My VBlogMag Amazon Retail store: http://astore.amazon.com/vblogmag-twenty

———————————————————————–

=================================================

Online video sponsor, Pass Ltd – their internet websites:

http://www.tester.co.united kingdom/?cmid=QmhzQjcxYjVlc1E9&afid=bFcwbzliNzVDc289&ats=K2EyUjZNTDh3UTA9 – Examination Products and Examination-meter suppliers and

http://www.calibrate.co.united kingdom/?cmid=QmhzQjcxYjVlc1E9&afid=bFcwbzliNzVDc289&ats=S3Yxd2tOMjVISzA9 – Calibration and support of exam tools

=================================================

Additional dialogue and link to NASA information below:

http://mjlorton.com/forum/index.php?matter=244.

In this online video:

* Deciding upon the correct wire gauge (AWG – American Wire Gauge) for the crimp connector.

* Employing the correct applications to strip the insulation from the wire.

* The correct way to insert the wire into the crimp connector

* Employing the correct crimp applications to crimp the connector

* How to implement warmth shrink accurately to the wire and crimp connector.