2 Years’ Warranty for Nickel Alloy Hastelloy C22 UNS N06022 for Saudi Arabia Factories

Our team through professional training. Skilled professional knowledge, strong sense of service, to meet the service needs of customers for 2 Years’ Warranty for Nickel Alloy Hastelloy C22 UNS N06022 for Saudi Arabia Factories, We fully welcome customers from all over the world to establish stable and mutually beneficial business relationships, to have a bright future together.

HY HC-22 Material grades and equivalents

Hastelloy C-22/UNS N06022/SEW VDIUV W.Nr.2.4602 NiCr21Mo14W/AFNOR NU-30M

HY HC-22Chemical composition:

|

Alloy |

% |

Ni |

Cr |

Mo |

Fe |

W |

Co |

C |

Mn |

Si |

V |

P |

S |

|

C |

Min. |

balance |

14.5 |

15 |

4 |

3 |

|||||||

|

Max. |

16.5 |

17 |

7 |

4.5 |

2.5 |

0.08 |

1 |

1 |

0.35 |

0.04 |

0.03 |

||

|

C22 |

Min. |

balance |

20 |

12.5 |

2 |

2.5 |

|||||||

|

Max. |

22.5 |

14.5 |

6 |

3.5 |

2.5 |

0.02 |

0.5 |

0.08 |

0.35 |

0.02 |

0.02 |

HY HC-22Physical properties

|

Density |

8.9 g/cm³ |

|

Melting point |

1325-1370 ℃ |

HY HC-22 Alloy minimum mechanical properties in the room temperature

|

Alloy |

Tensile Strength |

Yield strength |

Elongation |

|

A 5 % |

|||

|

HY HC-22 |

690 |

283 |

40 |

Characteristic as below :

HY HC22 is a omnipotent of nickel, chromium and molybdenum mixed alloy, with better corrosion resistance performance than other alloys, for example, Hastelloy C276 alloy, C4 alloy and 625 alloy. HY HC22 have a good resistance performance to pitting, crevice corrosion and stress corrosion cracking, have excellent inoxidability water medium performance, including the wet-chlorine, nitric acid or oxidizing acid mixed acid with chloride ion. Meantime, HY HC22 possesses perfect resistance to reduction and oxidation of processing enviroments, then it can be used in some complicated environment or with many different manufacture target factory depend on the omnipotent performance. HY HC22 possess prominent resistance performance to different chemical environments, including strong oxidizing matter, such as iron chloride, copper chloride, chlorine, heat pollution liquid(organic and inorganic), formic acid, acetic acid, acetyl oxide, sea water and salting liquid and so on. HY HC22 alloy can resist the grain boundary precipitate form when jointing heat affected zone, this performance made it can applied in many kinds of chemical processing.

HY HC-22Metallurgical structure

Hastelloy C22 is face-centered cubic lattice structure.

HY HC-22Corrosion resistance

HY HC-22 alloy suit for many kinds of chemical process industry which contain the oxidizing medium and reductant. High molybdenum and chromium content make it can resist the chloride corrosion, and tungsten make this corrosion resistance better. HY HC22 is one of a few material that can resist the corrosion of moist chlorine, hypochlorite and chlorine dioxide, this alloyhave prominent corrosion resistanceto high concentration chlorate( iron chloride and copper chloride).

HY HC-22Application field:

HY HC22 is widely used in the chemical field and petrifaction field, such as the element of chloride organic and catalyze system. This material especially suit for high temperature environments, impure inorganic acid and organic acid (such as formic acid and acetic acid), sea-water corrosion environments.

HY HC-22Other application field:

1. Acetic acid/acetyl oxide

2.Acid dipping

3.Cellophane paper manufactures

4.Chloride system

5. Complicated mixed acid

6. Electrogalvanizing groove roller

7.Expansion bellows

8.Flue gas washer system

9.Geothermal well

10.Fluorine hydride furnace cleaner

11.Incineration cleaner system

12. Nuclear fuel regeneration

13. Pesticide manufacture

14.Phosphoric acid manufacture

15.Acid cleaning system

16.Plate heat exchanger

17. Selectivity filter system

18.Sulfur dioxide cooling tower

19. Sulfonating system

20.Tubing heat exchanger

21. Resurfacing welding valve

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

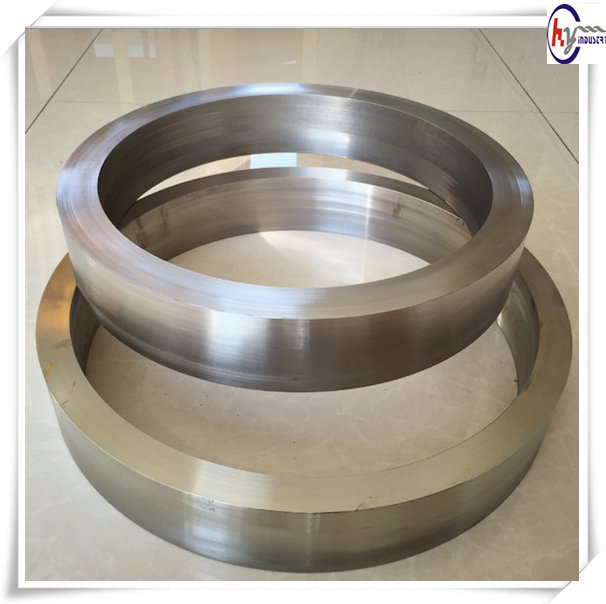

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

Experimentální odlévání monelu na katedře strojírenské technologie při TU v Liberci – Monel je slitina niklu a mědi. Název Monel je registrován jako trademark americké firmy Specific Metals Corporation. Monel vyrobil v roce 1901 Robert Crooks Stanley, slitinu pojmenoval po tehdejším prezidentu firmy Ambrose Monellovi.

Monel vykazuje výborné mechanické vlastnosti a chemickou odolnost v náročném prostředí, např. v dlouhodobém kontaktu se slanou vodou, ale i v chemickém průmyslu. Často bývá využit tam, kde již nedostačují vlastnosti nerezových ocelí.

Monel is a group of nickel alloys, largely composed of nickel (up to sixty seven%) and copper, with tiny quantities of iron, manganese, carbon, and silicon. More powerful than pure nickel, Monel alloys are resistant to corrosion by quite a few agents, like promptly flowing seawater. They can be fabricated quickly by very hot- and chilly-working, machining, and welding.[2]

Monel was made by David H. Browne, main metallurgist for Global Nickel Co. Monel alloy four hundred is a binary alloy of the identical proportions of nickel and copper as is found naturally in the nickel ore from the Sudbury (Ontario) mines and is thus thought of a puritan alloy. Monel was named following business president Ambrose Monell, and patented in 1906.[three] Just one L was dropped, for the reason that loved ones names were being not allowed as trademarks at that time.[one] The title is now a trademark of Specific Metals Corporation.

.025″ slash, 140sfm, VBMT 331 insert