20 Years Factory Nickel Alloy Hastelloy C-276 UNS N10276 for Benin Factories

In the past few years, our company absorbed and digested advanced technologies both at home and abroad. Meanwhile, our company staffs a team of experts devoted to the development of 20 Years Factory Nickel Alloy Hastelloy C-276 UNS N10276 for Benin Factories, Welcome to build the well and long standing business relationships with our company to create a glorious future together .customers' satisfaction is our eternal pursuit

HY HC-276 Material grades and equivalents

HY HC-276 / GB NS334 / UNS N10276 / SEW VDIUV W.Nr.2.4819 NiMo16Cr15W / BS NC17D / NiMo16Cr15

HY HC-276 Chemical composition

|

Alloy |

% |

Ni |

Cr |

Mo |

Fe |

W |

Co |

C |

Mn |

Si |

V |

P |

S |

|

C |

Min. |

balance |

14.5 |

15 |

4 |

3 |

|||||||

|

Max. |

16.5 |

17 |

7 |

4.5 |

2.5 |

0.08 |

1 |

1 |

0.35 |

0.04 |

0.03 |

||

|

C276 |

Min. |

balance |

14.5 |

15 |

4 |

3 |

|||||||

|

Max. |

16.5 |

17 |

7 |

4.5 |

2.5 |

0.01 |

1 |

0.08 |

0.35 |

0.04 |

0.03 |

HY HC-276 Physical properties:

|

Density |

8.9 g/cm³ |

|

Melting point |

1325-1370 ℃ |

HY HC-276 Alloy m inimum mechanical properties in the room temperature

|

Alloy state |

Tensile strength |

Yield strength |

Elongation |

|

C /C276 |

690 |

283 |

40 |

Characteristic as below

1. Excellent corrosion resistance to most of corrosion media in oxidation and reduction environments.

2. Excellent resist pitting, crevice corrosion and stress corrosion cracking performance.

HY HC-276 Metallurgical structure

C276 is face-centered cubic lattice structure.

HY HC-276 Corrosion resistance

C276 alloy suit for many kinds of chemical process industry which contain the oxidizing medium and reductant. High molybdenum and chromium content make it can resist the chloride corrosion, and tungsten make it corrosion resistance better.C276 is one of a few material that can resist the corrosion of most chlorine, hypochlorite and chlorine dioxide, this alloy have prominent corrosion resistance to high concentration chlorate( iron chloride and copper chloride).

HY HC-276 Application field:

C276 is widely used in the chemical field and petrifaction field, such as the element of chloride organic and catalyze system. This material especially suit for high temperature environment, impure inorganic acid and organic acid (such as formic acid and acetic acid), sea-water corrosion environment.

HY HC-276 Other application field:

1. The digester and bleacher in the use of paper pulp and paper making industry.

2. Absorption tower, re-heater and fan in the FGD system.

3. The equipment and parts in the use of acidic gas environments.

4. Acetic acid and anhydride reaction generator

5. Sulfur acid cooling

6. MDI

7.Manufacture and processing of impure phosphoric acid.

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

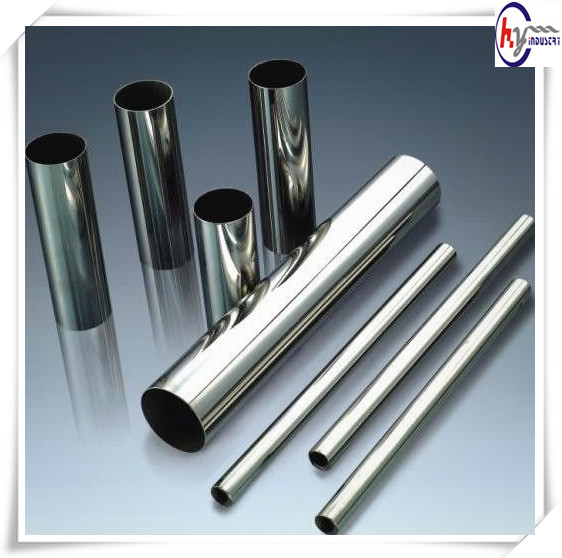

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

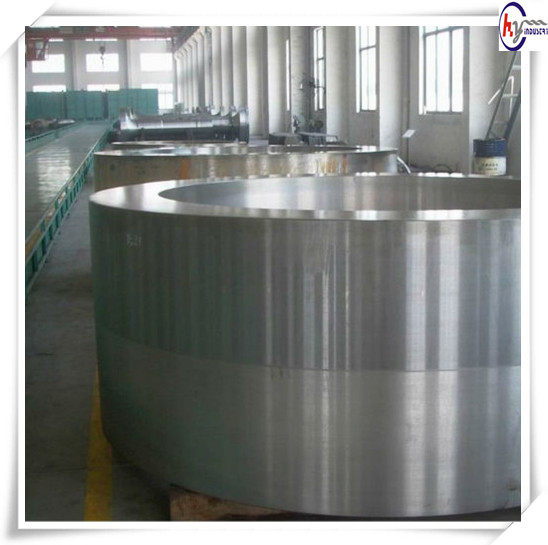

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

Movie da parte di Costanzo Perico

High successful HRSA turbine blade roughing on Starrag LX 051

- Materials technical specs: Nimonic 80A, NiCr20TiAl (2.4952)

- MMR: sixteen.nine cm3/min