20 Years manufacturer Cobalt Alloy Refractaloy 26 UNS R30188 Export to Serbia

We are experienced manufacturer. Wining the majority of the crucial certifications of its market for 20 Years manufacturer Cobalt Alloy Refractaloy 26 UNS R30188 Export to Serbia, We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

HY R26 Material grades and equivalents

R26/GB GH26/UNS Refractaloy-26/SEW VDIUV W. Nr.1.2888

HY R26 Chemical composition

|

Alloy |

% |

Ni |

Cr |

Fe |

Mo |

Ti |

Co |

|

R26 |

Min |

Rest |

|||||

|

Max |

37 |

18 |

3.0 |

2.7 |

20 |

HY R26 Characteristic

HY R26 has excellent resistance to relaxation, anti creep property, permanence property and resistance to stress corrosion resistance.

Physical properties:

Density:9.14 g/cm3

Melting point:1300℃-1330 ℃

Alloy sheet mechanical properties in the room temperature:

| Alloy Status | Tensile strength Rm N/mm² |

Yield strengthRP0.2 N/mm² | Elongation A5 % |

| Solution Treatment | 925 | 610 | 10 |

HY R26 Application field

HY R26 is a material can be applied in turbine engine blade and fastener.

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

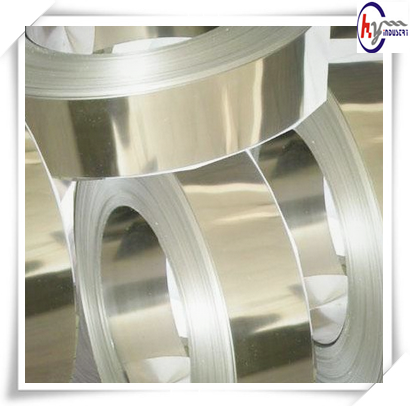

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

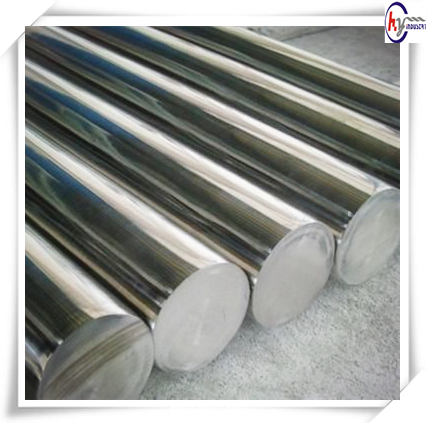

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

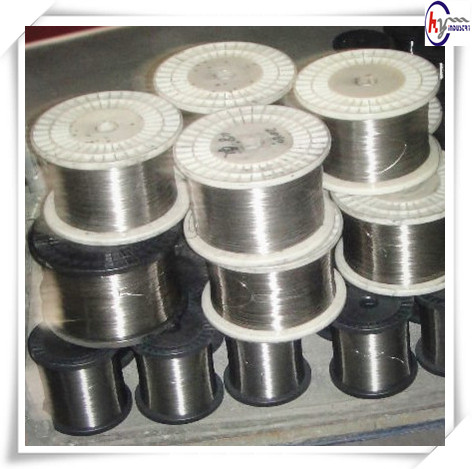

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

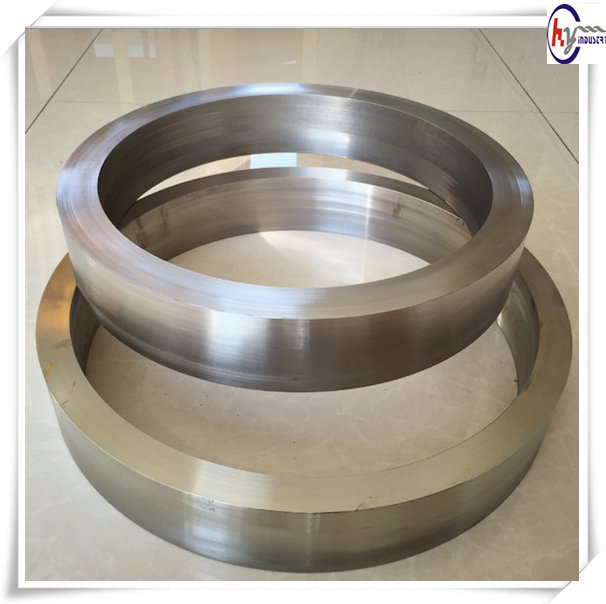

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

Riporto(placcatura)con filo Nimonic 80 dia. one.2 eseguito con inverter multiprocesso Weldtronic Synertech 8004 Digit in pulsato sinergico.

NB .Il lampeggio dell’arco è presente solo nella ripresa effettuata dalla fotocamera digitale usata probabilmente a causa di interferenza con l’intenso arco luminoso.

Details: belda1@tiscali.it

Experimentální odlévání monelu na katedře strojírenské technologie při TU v Liberci – Monel je slitina niklu a mědi. Název Monel je registrován jako trademark americké firmy Specific Metals Corporation. Monel vyrobil v roce 1901 Robert Crooks Stanley, slitinu pojmenoval po tehdejším prezidentu firmy Ambrose Monellovi.

Monel vykazuje výborné mechanické vlastnosti a chemickou odolnost v náročném prostředí, např. v dlouhodobém kontaktu se slanou vodou, ale i v chemickém průmyslu. Často bývá využit tam, kde již nedostačují vlastnosti nerezových ocelí.

Monel is a group of nickel alloys, largely composed of nickel (up to sixty seven%) and copper, with tiny quantities of iron, manganese, carbon, and silicon. More powerful than pure nickel, Monel alloys are resistant to corrosion by quite a few agents, like promptly flowing seawater. They can be fabricated quickly by very hot- and chilly-working, machining, and welding.[2]

Monel was made by David H. Browne, main metallurgist for Global Nickel Co. Monel alloy four hundred is a binary alloy of the identical proportions of nickel and copper as is found naturally in the nickel ore from the Sudbury (Ontario) mines and is thus thought of a puritan alloy. Monel was named following business president Ambrose Monell, and patented in 1906.[three] Just one L was dropped, for the reason that loved ones names were being not allowed as trademarks at that time.[one] The title is now a trademark of Specific Metals Corporation.