2016 High quality Nickel Alloy Inconel 601 UNS N06601 in Dubai

With our excellent management, strong technical capability and strict quality control system, we continue to provide our clients with reliable quality, reasonable prices and excellent services. We aim at becoming one of your most reliable partners and earning your satisfaction for 2016 High quality Nickel Alloy Inconel 601 UNS N06601 in Dubai, Adhering to the business principle of mutual benefits, we have won good reputation among our customers because of our perfect services, quality products and competitive prices. We warmly welcome customers from home and abroad to cooperate with us for common success.

HY 601 Material grades and equivalents

Inconel 601 / GB NS313 / UNS N06601/W.Nr.2.4851 NiCr23Fe / AFNOR NC23FeA

HY 601 Chemaical composition:

|

Alloy |

% |

Ni |

Cr |

Fe |

C |

Mn |

Si |

Cu |

Al |

P |

S |

|

601 |

Min. |

58 |

21 |

1.0 |

|||||||

|

Max. |

63 |

25 |

balance |

0.1 |

1.5 |

0.5 |

1 |

1.7 |

0.02 |

0.015 |

HY 601 Physical properties

|

Density |

8.1g/cm3 |

|

Melting point |

1320-1370℃ |

HY 601 Alloy m inimum mechanical properties in the room temperature

|

Alloy state |

Tensile strength |

Yield strength |

Elongation |

Brinell hardness |

|

Annealing treatment |

650 |

300 |

30 |

- |

|

Solution treatment |

600 |

240 |

30 |

≤220 |

Characteristic as below:

1. Excellent inoxidability in the high temperature.

2. Good resistance to carbonizing.

3. Good inoxidabilitiy in sulfur atmosphere

4.Good mechanical property in both room temperature and high temperature.

5.Good resistance to stress corrosion cracking, 601 have high creep rupture strength since it limits the carbon content and grain size, so recommend to use for above 500℃ environment.

HY 601 Metallurgical structure:

601 is face-centered cubic lattice structure.

HY 601 Corrosion resistance

One of the mainly performance of 601 is inexorability in high temperature, even in very inclement conditions. If in the process of heating and cooling cycle, 601 can generate the dense layer of oxide film to get high spalling resistance. 601 have good carbonation resistance. With excellent inoxidability in the high temperature of sulfur atmosphere since it has high chromium and aluminum content.

HY 601 Application field:

1.The tray,basket and tool clamp in the heat treatment factory.

2.Steel shares at annealing and radiation control, high-speed gas burners, Industrial furnace silk screen.

3.Separate tank of ammonia reforming and catalytic support grid of nitric acid producing.

4.Exhaust system parts

5.Solid waste incinerator’s combustion chamber

6.Channel support and soot dealing parts.

7.Detoxification exhaust system components

8.Oxygen re-heater

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

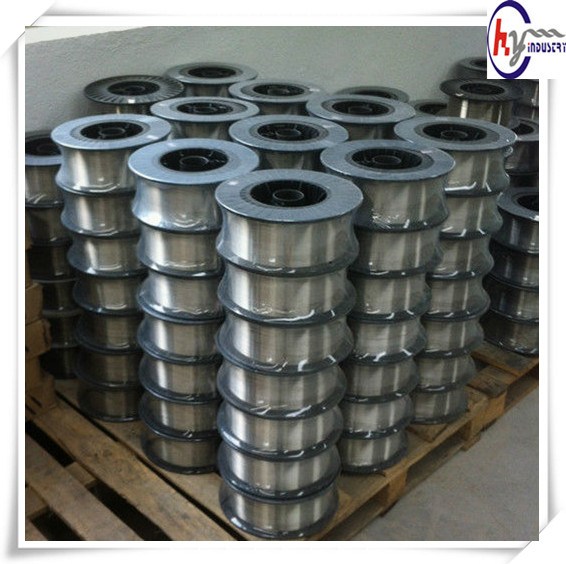

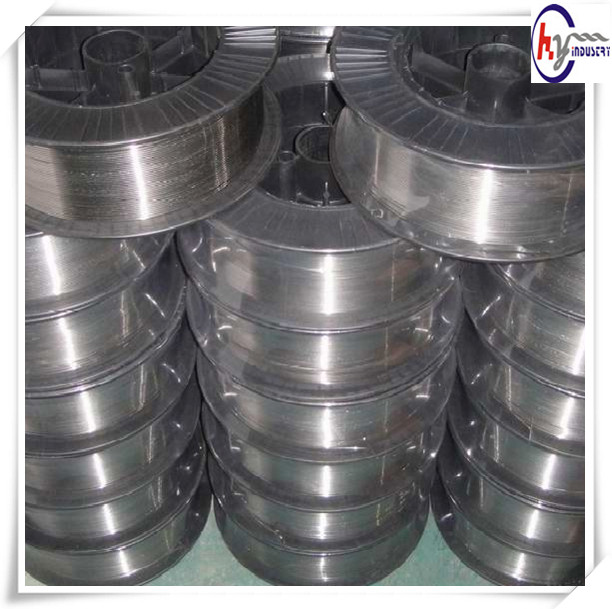

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

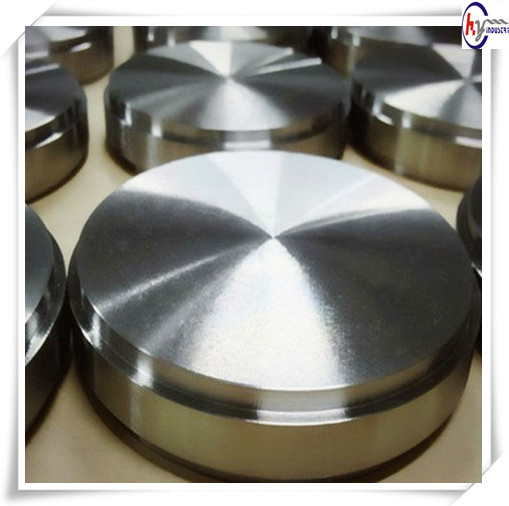

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

Qingdao NPA Marketplace Co. Ltd is a foremost manufacturer specialized in centrifugal casting tube and static castings of warmth resistant alloys, which include ethylene cracking furnace tube, reformer furnace tube, CAL(constant annealing traces) &CGL(constant galvanizing traces) furnace roller and radiant tube, glass lehr roller and warmth/have on resistant castings. The annual potential is 9000 tons centrifugal casting tube and 3500 tons static castings (500 tons precision castings).

Internet site: www.npa-china.com

Supplier foil、strip、sheet、coil、plate、wire、rod、bar、tube、pipe、flat ribbon、Profiled wire…

BuildingNo.1,Third Industrial District XiTou Village SongGang Town Bao’An District ShenZhen City GuangDong Province China