5 Years Factory Nickel Alloy Inconel 783 UNS R30783 to Bangkok Manufacturers

We keep improving and perfecting our products and service. At the same time, we work actively to do research and development for 5 Years Factory Nickel Alloy Inconel 783 UNS R30783 to Bangkok Manufacturers, Let's cooperate hand in hand to jointly make a beautiful future. We sincerely welcome you to visit our company or contact us for cooperation!

HY 783 Material grades and equivalents

Inconel 783 / Alloy 783 / UNS R30783

An oxidation resistant low coefficient of thermal expansion (low CTE) superalloy developed for gas turbine applications.

The alloy is strengthened by a precipitation-hardening heat treatment made possible by additions of niobium and aluminum. In addition, the aluminum content provides excellent resistance to oxidation at high temperature.

The alloy’s density is 5% less than those of superalloys such as INCONEL alloy 718. The combination of low expansion, high strength and excellent resistance to oxidation makes the alloy especially useful for gas turbine and steam turbine components.

The low expansion enables closer control of clearances and tolerances for greater power output and fuel efficiency.

Table 1 - Limiting Chemical Composition*, %

Chromium……………………………………………………………. 2.5-3.5

Nickel ……………………………………………………………….26.0-30.0

Iron ……………………………………………………………………24.0-27.0

Niobium…………………………………………………………………2.5-3.5

Aluminum………………………………………………………………5.0-6.0

Cobalt………………………………………………………………Remainder

Boron……………………………………………………………..0.003-0.012

Carbon………………………………………………………………0.03 max.

Manganese………………………………………………………..0.50 max.

Silicon……………………………………………………………….0.50 max.

Phosphorus……………………………………………………..0.015 max.

Sulfur ……………………………………………………………….0.005 max

Titanium…………………………………………………………………0.1-0.4

Copper……………………………………………………………….0.50 max

Physical Properties

Table 2 - Physical Constants

Density, g/cm3…………………………………………………………..7.81

lb/in3………………………………………………………….0.282

Melting Range, °F ……………………………………………..2437-2565

°C …………………………………………….1336-1407

Specific Heat, Btu/lb•°F (77°F)……………………………………0.109

J/kg•°C (25°C)……………………………………….455

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

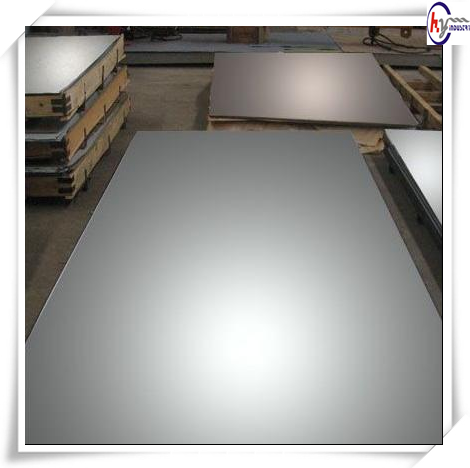

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

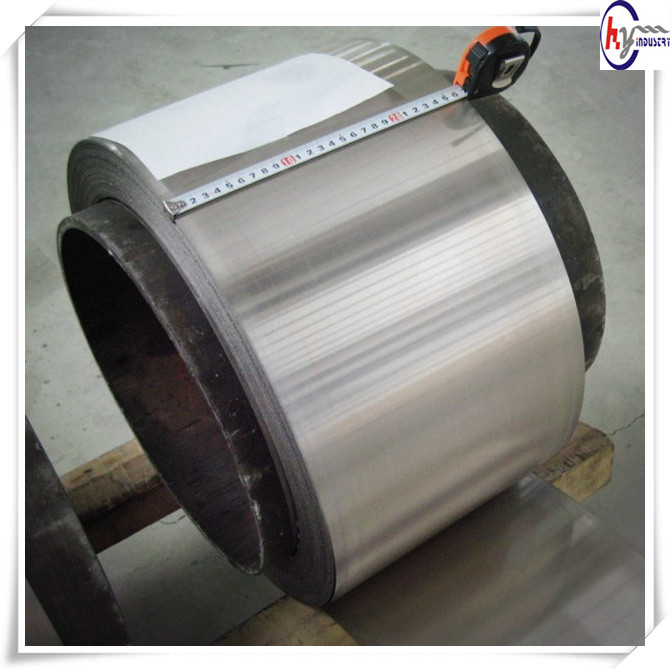

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

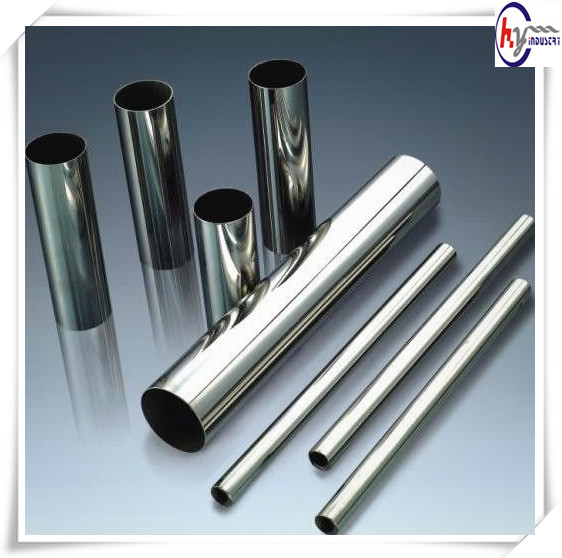

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

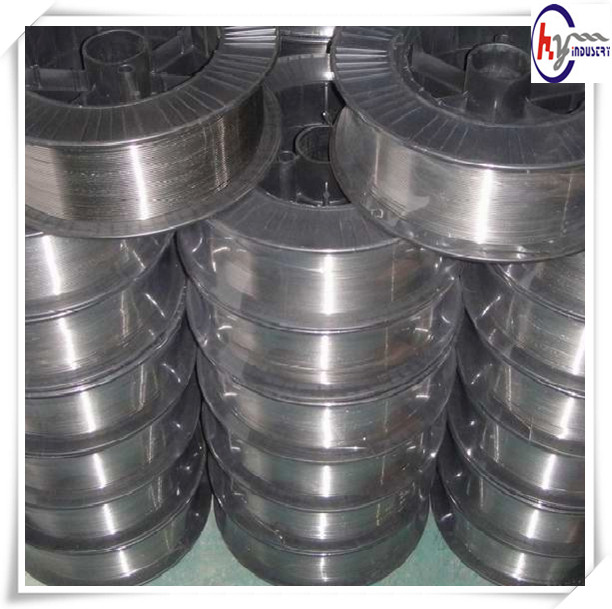

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

» Metal Tubes India is a GOVT. OF INDIA Acknowledged STAR EXPORT Dwelling & PED Accredited Maker

» Metal Tubes India is winner of All India Award for export excellence for 6 Consecutive Many years

» Metal Tubes India is an ISO 9001,ISO 14001,OHSAS 18001 Accredited company, our international CRISIL Ranking is SE 2B

» Metal Tubes India is European Force Machines Directive PED-97/23/EC qualified company

Ni 72., Cr fifteen.5, Fe 8. Mn 1. C .fifteen Cu .5 Si .5 S .015

Significant Efficiency Alloys stocks and produces this grade in the adhering to forms: Bar, wire, sheet, plate, coil, fasteners and forgings. Ask for quote on this grade.

Alloy 600 is a nickel-chromium alloy built for use from cryogenic to elevated temperatures in the selection of 2000 deg F(1093 deg C). The superior nickel material of the alloy allows it to retain substantial resistance less than lessening conditions and makes it resistant to corrosion by a range of natural and inorganic compounds. The nickel material gives it exceptional resistance to chloride-ion pressure-corrosion cracking and also offers exceptional resistance to alkaline options.

Inconel 600 Tube

ASME SB-163 ASME SB-516 ASME SB751 AMS 5580

UNS N06600 also offered in numerous forms like cap, elbow, erw pipes, fasteners, fittings, flange, plate, reducer, spherical bar, seamless pipes, sheet, tee and tube at industrial charge.

+ for extra info & specification about Inconel 600 remember to check out

http://www.steeltubesindia.internet/

Visit my site for additional Recommendations, Films, Do it yourself assignments and additional:

http://www.mjlorton.com/

—————————–Click “Display additional”—————————————

A information on making use of the correct applications to crimp connectors, strip wire and implement warmth shrink.

You should guidance my information generation by making use of my Amazon Retail store:

http://astore.amazon.com/m0711-twenty

Purchase these applications and connectors below: http://astore.amazon.com/m0711-twenty?node=ten&site=one

——————— Click “Display additional” ——————————-

My site and forum:- http://www.mjlorton.com

Donations and contributions:- http://www.mjlorton.com

My techie channel MJLorton – Solar Power and Digital Measurement Products – http://www.youtube.com/MJLorton

My Techie Amazon Retail store: http://astore.amazon.com/m0711-twenty

My other channel VBlogMag – For nearly any matter beneath the sun! – http://www.youtube.com/VBlogMag

My VBlogMag Amazon Retail store: http://astore.amazon.com/vblogmag-twenty

———————————————————————–

=================================================

Online video sponsor, Pass Ltd – their internet websites:

http://www.tester.co.united kingdom/?cmid=QmhzQjcxYjVlc1E9&afid=bFcwbzliNzVDc289&ats=K2EyUjZNTDh3UTA9 – Examination Products and Examination-meter suppliers and

http://www.calibrate.co.united kingdom/?cmid=QmhzQjcxYjVlc1E9&afid=bFcwbzliNzVDc289&ats=S3Yxd2tOMjVISzA9 – Calibration and support of exam tools

=================================================

Additional dialogue and link to NASA information below:

http://mjlorton.com/forum/index.php?matter=244.

In this online video:

* Deciding upon the correct wire gauge (AWG – American Wire Gauge) for the crimp connector.

* Employing the correct applications to strip the insulation from the wire.

* The correct way to insert the wire into the crimp connector

* Employing the correct crimp applications to crimp the connector

* How to implement warmth shrink accurately to the wire and crimp connector.