5 Years Factory Nickel Alloy Monel 400 UNS N04400 Wholesale to Indonesia

We always think and practice corresponding to the change of circumstance, and grow up. We aim at the achievement of a richer mind and body and the living for 5 Years Factory Nickel Alloy Monel 400 UNS N04400 Wholesale to Indonesia, If you are interested in any of our products and services, please don't hesitate to contact us. We are ready to reply you within 24 hours after receipt of your request and to create mutual un-limited benefits and business in near future.

HY M400 Material grades and equivalents

Nonel 400/ Alloy400 /UNS N04400 / SEW VDIUV W.Nr.2.4360 NiCu30Fe /BS NA 12 / AFNOR Nu 30

HY M400 Chemical composition

| Alloy |

% |

Ni |

Cu |

Fe |

C |

Mn |

Si |

S |

|

HY M400 |

Min. |

63 |

28 |

|||||

|

Max. |

34 |

2.5 |

0.3 |

2 |

0.5 |

0.024 |

HY M400 Physical properties

| Density |

8.83 g/cm³ |

|

Melting point |

1300-1390 ℃ |

HY M400 Alloy minimum mechanical properties in the room temperature

| Alloy state |

Tensile strength |

Yield strength |

Elongation |

|

HY M400 |

480 |

170 |

35 |

Characteristic as below:

HY M400 is an extremely combination property that use for largest amount and most widely corrosion resistance alloy. This alloy in the hydrofluoric acid and fluoride gas medium with excellent corrosion resistance, as well as to the hot concentrated alkali. At the same time, is also corrosion resistant to neutral solution, sea water, air, organic compounds. An important feature of this is generally do not generate a stress corrosion cracking, good cutting performance.

HY M400 Metallurgical structure

HY M400 alloy is high-intensity single-phase solid solution.

HY M400 Corrosion resistance

HY M400 alloy in the fluoride gas, hydrochloric acid, sulfuric acid, hydrofluoric acid and their derivatives have a very good corrosion resistance property, and possess better corrosion resistance more than the copper alloy in the sea water. Acid medium: HY M400have corrosion resistance in less than 85% consistency of sulfuric acid. HY M400is an important material that resistant to hydrofluoric acid. Water corrosion: HY M400 alloy in most corrosion cases of water, not only excellent corrosion resistance, but also less pitting, stress corrosion, the corrosion rate less than 0.025mm / a. High temperature corrosion: HY M400 for the work of the highest temperature at about 600 ℃ in general in the air, in the high temperature steam, the corrosion rate less than 0.026mm / a. Ammonia: HY M400 can be resistant to an hydrous ammonia and aminate conditions corrosion below 585 ℃ due to the high nickel.

HY M400 Application field:

HY M400 alloy is a multi-purpose material in many industrial applications:

1. Seamless water pipe in the power factory

2. Sea-water exchanger and evaporator

3. Sulfuric acid and hydrochloric acid environment

4. Crude distillation

5. Sea-water in the use of equipment and propeller shaft

6. Nuclear industry and used in the manufacture of uranium enrichment isotope separation equipment

7. Manufacturing hydrochloric acid equipment used in the production of pump and valve

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

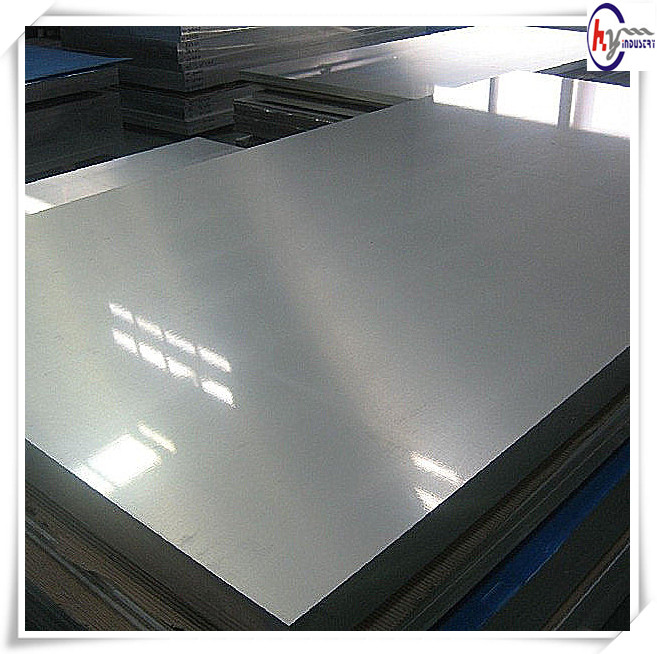

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

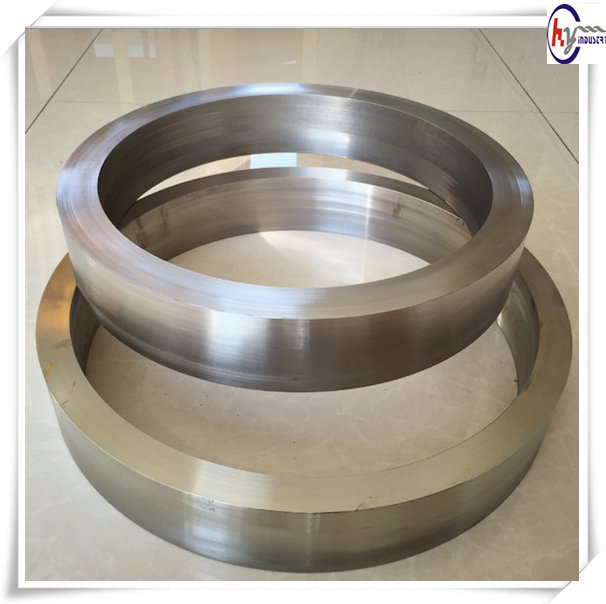

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

To comprehend that the utilizes for particular metals relate to their unique qualities.

To comprehend that the qualities of metals can be improved by generating alloys.

To recall that some of the hottest alloys, called ‘Smart Alloys’ can change their qualities on demand from customers.

Duplicate the table beneath. Working with a companion, entire as a great deal of the table as you can.

Very low density, powerful, resistant to corrosion, very good conductor of energy

Good conductor of energy, resistant to corrosion, quickly formed, flexible

Shiny, very resistant to corrosion, very unreactive, soft, quickly formed

Extremely powerful, very dense.

Lightweight buildings, plane, drinks cans, higher voltage cables.

Electrical wiring, h2o pipes.

Jewelry.

Substantial buildings and significant responsibility engineering these as bridges, trains, autos and so forth.

In pure metals the atoms prepare them selves closely collectively into regular styles. This tends to make them dense and also presents them numerous of their other helpful qualities.

The layer arrangement of the atoms permits the metals to transform form if a pressure is utilized. The layers can slip around every other.

This can be helpful if you want to form the steel but not so helpful if you want it to resist the pressure and be powerful.

By mixing two or additional metals collectively the regular arrangement of the atoms is disrupted. This stops the atoms forming layers and tends to make it harder for the atoms to slide around every other. The alloy is more robust than the pure metals.

Steel B

Steel A

Steel is an alloy. Pure iron is not powerful enough to be employed in buildings. Steel contains a smaller amount of carbon. This disrupts the layers of atoms in the steel and improves the toughness of the steel considerably.

Despite the fact that it is very powerful metal will corrode (rust) quickly and it has to be regularly protected from the consequences of h2o and air.

Stainless metal is an alloy that contains other metals these as Nickel and Chromium. Stainless metal has the toughness of metal mixed with the corrosion resistance of nickel and the shininess of chromium. This tends to make it a helpful materials in programs exactly where you will need toughness mixed with magnificence and corrosion resistance..

Clever Alloys

These are alloys that can ‘remember’ their primary form. If they are deformed they can return to their primary form.

Condition memory glasses

Condition memory Stent to continue to keep a blocked blood vessel open

Metals, Alloys and Clever Alloys

Finding out Objectives:

To comprehend that the utilizes for particular metals relate to their unique qualities.

To comprehend that the qualities of metals can be improved by generating alloys.

To recall that some of the hottest alloys, called ‘Smart Alloys’ can change their qualities on demand from customers.

NEW 2016 Chrysler three hundred S Alloy Edition Sedan with a Gloss Black Paint finish. AWD that seats five with a three.two L V-six engine and an eight velocity computerized transmission. 19″ alluminum alloy rims with Michelin Primacy MXM4 tires. This sedan will come thoroughly loaded with keyless entry, distant get started, power locks, home windows, mirrors, Beats by Dre audio system, AM/FM, Sirius Sat radio, Lcd display screen in the entrance with back up digicam, leather all over with heated entrance and rear seats and so significantly a lot more. Come check out it out at Ponoka Chrysler and see what else it has to present, we are located on the south conclusion of Ponoka just off of HWY 2A.

Stock# 16C37644

Sarah Johnson,

Ponoka Chrysler

6510 39th Ave Ponoka, AB T4J 1J8

Toll Cost-free: 1(800) 265-6851

Cellphone: (403) 783-5383

Fax: (403) 783-8140

E-mail: sjohnson@ponokachrysler.com

Like us on Fb- https://www.facebook.com/PonokaChrysler/

Abide by us on Instargram- https://www.instagram.com/ponokadodge/

Abide by us on Twitter- https://twitter.com/PonokaDodgeRam

Abide by us on Pintrest- https://www.pinterest.com/ponokachrysler/