5 Years Factory Nickel cobalt base alloy AMS 5844 MP35N to Auckland Manufacturer

Our company puts emphasis on the management, the introduction of talented personnel, and the construction of staff building, trying hard to improve the quality and liability consciousness of staff members. Our company successfully attained IS9001 Certification and European CE Certification of 5 Years Factory Nickel cobalt base alloy AMS 5844 MP35N to Auckland Manufacturer, Contact with us today! We are ready for the market service now!

HY MP35N Material grades and equivalents

MP35N/UNS R30035/ W.Nr 2.4999/ AMS 5844

Introduction:

HY MP35N is a nickel-cobalt base alloy of the Multiphase alloy system that has a unique combination of properties-ultra high strength, toughness, ductility and outstanding corrosion resistance. The alloy is work-strengthened and aged to obtain strength levels of 260 to 300 ksi(1793-2068 MPa). HY MP35N alloy resists corrosion in hydrogen sulfide, salt water and other chloride solution, as well as the mineral acids(nitric, hydrochloric, sulfuric).In addition, it has exceptional resistance to crevice and stress corrosion cracking in sea water and other hostile environments.

Chemical composition:

|

Weight% |

Ni |

Co |

Cr |

Mo |

Ti |

Fe |

Si |

Mn |

P |

B |

S |

C |

|

HY MP35N |

33 |

Balance |

19 |

9 |

1 |

1 |

0.15 |

0.15 |

0.015 |

0.01 |

0.01 |

0.03 |

|

37 |

21 |

10.5 |

Max |

Max |

Max |

Max |

Max |

Max |

Max |

Max |

Mechanical properties:

|

MP35N Alloy |

Ultimate Tensile |

0.2% Offset Yield |

Elongation in |

Reduction of Area |

Hardness |

Shear |

|

|

Typical Properties |

130 ksi(896 MPa) |

55 ksi(379 MPa) |

65% |

75% |

90 HRB |

— |

|

|

Typical Properties |

290 ksi(2000 MPa) |

280 ksi(1931 MPa) |

10% |

45% |

51 HRC |

— |

|

|

AMS 5844 Specification Requirements after Aging 4 Hours at 1000-1200℉ |

260 ksi(1795 MPa),min. |

230 ksi(1585 MPa),min. |

8%,min. |

35%,min. |

— |

150 ksi(1034 Mpa),min. |

|

The above data are longitudinal properties.

*Tensile properties will change depending on product size.

**Not required by AMS 5844, but this is guaranteed shear strength.

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

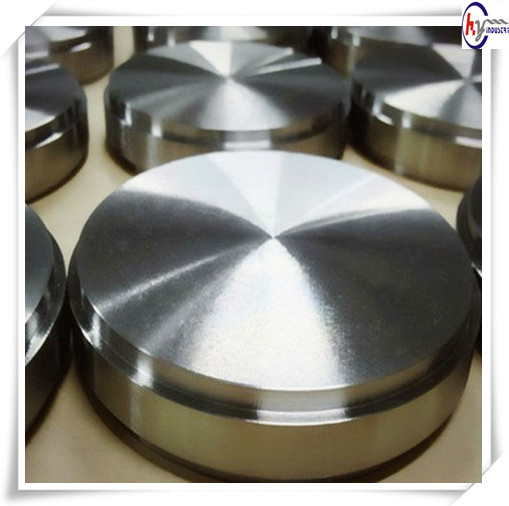

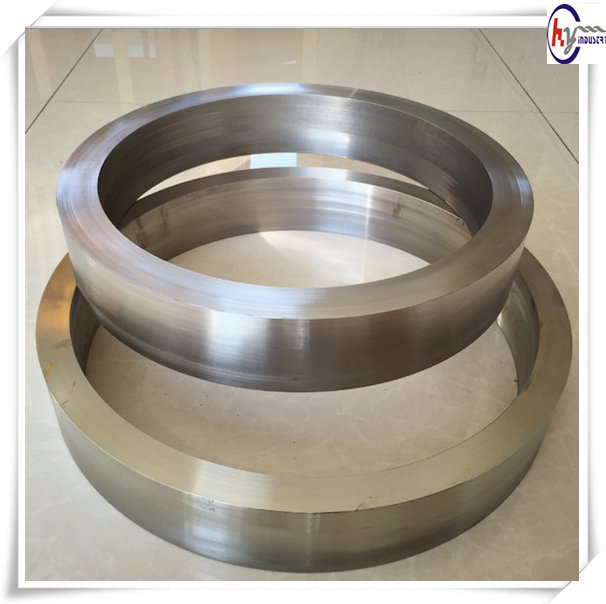

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

A nitinol wire/form memory alloy inchworm that walks across a table employing only warmth. The warmth is supplied by electrical existing heating up the skinny nitinol wire, causing it to return to its remembered form, a compressed coil in this scenario. A V-formed spring returns it to the commencing form.

Guidance RimstarOrg on Patreon https://www.patreon.com/user?u=680159

Subscribe for new films every single week http://www.youtube.com/user/rimstarorg?sub_affirmation=1

Go to the principal channel webpage below https://youtube.com/rimstarorg

See also:

How to Make Nitinol Wire Inchworm (Shape Memory Alloy)

https://www.youtube.com/look at?v=getfzfZJjHM

Nitinol Wire – How to Use it

https://www.youtube.com/look at?v=4Yi4epJ83EE

How a Rocket Performs/Earth to Area Eg SpaceX Falcon 9 and Dragon

https://www.youtube.com/look at?v=L0AMQ6kRNMA

My webpage about this nitinol wire inchworm:

http://rimstar.org/science_electronics_tasks/nitinol_wire_inchworm_form_memory_alloy_handmade.htm

Adhere to at the rear of-the-scenes on:

Twitter https://twitter.com/#!/RimStarz

Google+ https://additionally.google.com/116395125136223897621

Fb https://www.fb.com/rimstarorg

http://rimstar.org

The inspiration came from this one:

https://www.youtube.com/look at?v=DW4WaTmoZ3c

Essence – audio by audionautix.com

Discovery and Science Channel’s How It truly is Designed Alloy Wheels episode.

All copyrights go to their respective homeowners.