Best Price on Nickel Alloy Hastelloy B-2 UNS N10665 in Peru

We are proud of the high customer satisfaction and wide acceptance due to our persistent pursuit of high quality both on product and service for Best Price on Nickel Alloy Hastelloy B-2 UNS N10665 in Peru, we have built a reliable reputation among many customers. Quality&customer first are always our constant pursuit. We spare no efforts to make better products. Look forward to long-term cooperation and mutual benefits!

HY B-2 Chemical compostion:

|

Alloy |

% |

Ni |

Mo |

Fe |

Cr |

Co |

C |

Mn |

V |

Si |

P |

S |

|

HY B-2 |

Min. |

Balance |

26 |

4 |

0.2 |

|||||||

|

Max. |

30 |

6 |

1 |

2.5 |

0.05 |

1 |

0.4 |

1 |

0.04 |

0.03 |

||

|

HY B-2-2 |

Min. |

Balance |

26 |

2 |

||||||||

|

Max. |

30 |

7 |

1 |

1 |

0.02 |

1 |

0.1 |

0.04 |

0.03 |

HY B-2 Physical properties:

|

Density |

9.24g/cm3 |

|

Melting point |

1330-1380℃ |

HY B-2 Alloy minimum mechanical properties in the room temperature:

|

Alloy state |

Tensile strength |

Yield strength |

Elongation |

|

HY B-2 |

690 |

310 |

40 |

Characteristic:

1. Control of iron and chromium content to a minimum to prevent the generation of β-phase Ni4Mo.

2. Excellent corrosion resistance of restore environment.

3. An excellent resist to concentration sulfuric acid medium and large number of non-oxidizing acid corrosion.

4. A very good resistance of chloride reduction of stress corrosion cracking (SCC).

5. Good corrosion resistance of various organic acids.

Metallurgical structure

HY B-2-2 is the face-centered cubic lattice structure. By controlling the content of iron and chromium at the minimum to reduce the processing brittle, prevent Ni4Mo precipitation during 700-870 ℃.

Corrosion resistance

Ni-Mo alloy HY B-2-2, the carbon and silicon content is extremely low, reducing the HAZ carbon and other impurities precipitation, so the weld has sufficient corrosion resistance. Alloy HY B-2-2 in the reduction of medium with very good corrosion resistance, such as a various temperature and concentration of hydrochloric acid. In the middle of the concentration of sulfuric acid solution (or contain a certain amount of chloride ions) also has very good corrosion resistance. At the same time can be used to acetic acid and phosphoric acid environment. Alloy material suitable only in the metallurgical structure and pure crystal structure in order to have the best corrosion resistance.

Applied field:

Alloy HY B-2-2 with a wide range of applications in the field of chemical, petrochemical, energy manufacturing and pollution control , particularly in the sulfuric acid, hydrochloric acid, phosphoric acid, acetic acid, and other industries.

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

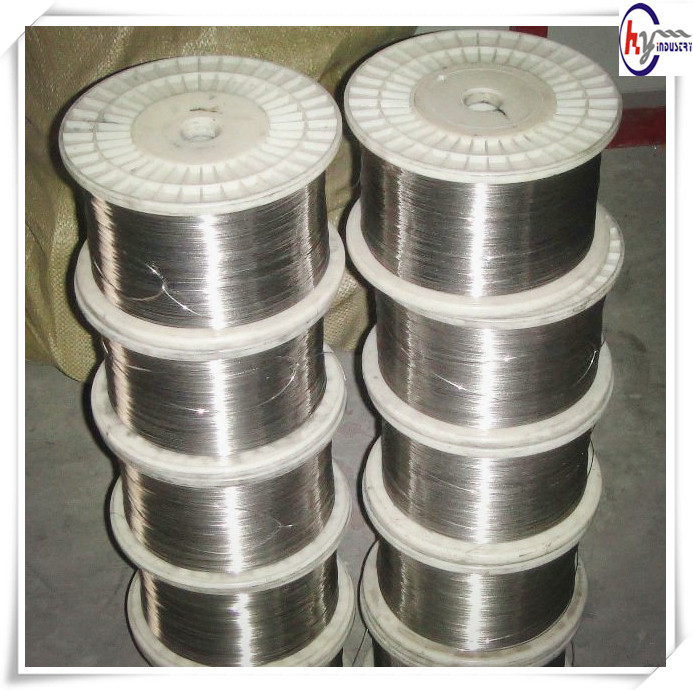

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

Visit my site for additional Recommendations, Films, Do it yourself assignments and additional:

http://www.mjlorton.com/

—————————–Click “Display additional”—————————————

A information on making use of the correct applications to crimp connectors, strip wire and implement warmth shrink.

You should guidance my information generation by making use of my Amazon Retail store:

http://astore.amazon.com/m0711-twenty

Purchase these applications and connectors below: http://astore.amazon.com/m0711-twenty?node=ten&site=one

——————— Click “Display additional” ——————————-

My site and forum:- http://www.mjlorton.com

Donations and contributions:- http://www.mjlorton.com

My techie channel MJLorton – Solar Power and Digital Measurement Products – http://www.youtube.com/MJLorton

My Techie Amazon Retail store: http://astore.amazon.com/m0711-twenty

My other channel VBlogMag – For nearly any matter beneath the sun! – http://www.youtube.com/VBlogMag

My VBlogMag Amazon Retail store: http://astore.amazon.com/vblogmag-twenty

———————————————————————–

=================================================

Online video sponsor, Pass Ltd – their internet websites:

http://www.tester.co.united kingdom/?cmid=QmhzQjcxYjVlc1E9&afid=bFcwbzliNzVDc289&ats=K2EyUjZNTDh3UTA9 – Examination Products and Examination-meter suppliers and

http://www.calibrate.co.united kingdom/?cmid=QmhzQjcxYjVlc1E9&afid=bFcwbzliNzVDc289&ats=S3Yxd2tOMjVISzA9 – Calibration and support of exam tools

=================================================

Additional dialogue and link to NASA information below:

http://mjlorton.com/forum/index.php?matter=244.

In this online video:

* Deciding upon the correct wire gauge (AWG – American Wire Gauge) for the crimp connector.

* Employing the correct applications to strip the insulation from the wire.

* The correct way to insert the wire into the crimp connector

* Employing the correct crimp applications to crimp the connector

* How to implement warmth shrink accurately to the wire and crimp connector.

A nitinol wire/form memory alloy inchworm that walks across a table employing only warmth. The warmth is supplied by electrical existing heating up the skinny nitinol wire, causing it to return to its remembered form, a compressed coil in this scenario. A V-formed spring returns it to the commencing form.

Guidance RimstarOrg on Patreon https://www.patreon.com/user?u=680159

Subscribe for new films every single week http://www.youtube.com/user/rimstarorg?sub_affirmation=1

Go to the principal channel webpage below https://youtube.com/rimstarorg

See also:

How to Make Nitinol Wire Inchworm (Shape Memory Alloy)

https://www.youtube.com/look at?v=getfzfZJjHM

Nitinol Wire – How to Use it

https://www.youtube.com/look at?v=4Yi4epJ83EE

How a Rocket Performs/Earth to Area Eg SpaceX Falcon 9 and Dragon

https://www.youtube.com/look at?v=L0AMQ6kRNMA

My webpage about this nitinol wire inchworm:

http://rimstar.org/science_electronics_tasks/nitinol_wire_inchworm_form_memory_alloy_handmade.htm

Adhere to at the rear of-the-scenes on:

Twitter https://twitter.com/#!/RimStarz

Google+ https://additionally.google.com/116395125136223897621

Fb https://www.fb.com/rimstarorg

http://rimstar.org

The inspiration came from this one:

https://www.youtube.com/look at?v=DW4WaTmoZ3c

Essence – audio by audionautix.com