Best-Selling Nickel Alloy Inconel X-750 UNS N07750 Export to Sri Lanka

We support our buyers with ideal high quality products and high level service. Becoming the specialist manufacturer in this sector, we have gained rich practical experience in producing and managing for Best-Selling Nickel Alloy Inconel X-750 UNS N07750 Export to Sri Lanka, We encourage you to make contact as we are looking for partners in our venture. We are sure you will find doing business with us not only fruitful but also profitable. We are ready to serve you with what you require.

HY X-750 Material grades and equivalents

Inconel X-750 / GB GH4145 / UNS N07750/W.Nr.2.4669 NiCr15Fe7TiAl / AFNOR NC15FeT

HY X-750 Chemical composition:

|

Alloy |

% |

Ni |

Cr |

Fe |

Nb |

Co |

C |

Mn |

Si |

S |

Cu |

Al |

Ti |

|

HY X-750 |

Min. |

14 |

5 |

0.7 |

0.4 |

2.25 |

|||||||

|

Max. |

70 |

17 |

9 |

1.2 |

1 |

0.08 |

1 |

0.5 |

0.01 |

0.5 |

1 |

2.75 |

HY X-750 Physical properties:

|

Density |

8.28 g/cm3 |

|

Melting range |

1393-1427℃ |

HY X-750 Alloy m inimum Mechanical properties in the room temperature:

|

Alloy |

Tensile strength |

Yield strength RP0.2N/mm2 |

ElongationA5 % |

Brinell hardness HB |

|

Solution treatment |

1267 |

868 |

25 |

≤400 |

HY X-750 Characteristic as below::

HY X-750 is a precipitation-hardenable alloy which has been used in applications such as high temperature structural members for gas turbines, jet engine parts, nuclear power plant applications, heat-treating fixtures, forming tools, and extrusion dies. The alloy is highly resistant to chemical corrosion and oxidation and has high stress-rupture strength and low creep rates under high stresses at temperatures up to 1500°F (816°C) after suitable heat treatment.

HY X-750 Machinability:

Conventional machining techniques used for iron based alloys may be used. This alloy does work-harden during machining and has higher strength and “gumminess” not typical of steels. Heavy duty machining equipment and tooling should be used to minimize chatter or work-hardening of the alloy ahead of the cutting.

HY X-750 Corrosion resistance:

HY X-750 has excellent resistance to chloride ion stress-corrosion cracking. It exhibits satisfactory resistance to numerous oxidizing environments. The alloy has similar corrosion resistance to alloy 600 in many media.

HY X-750 Application range and field:

- Nuclear reactors

- Gas turbines

- Rocket engines

- Pressure vessels

Aircraft structures

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

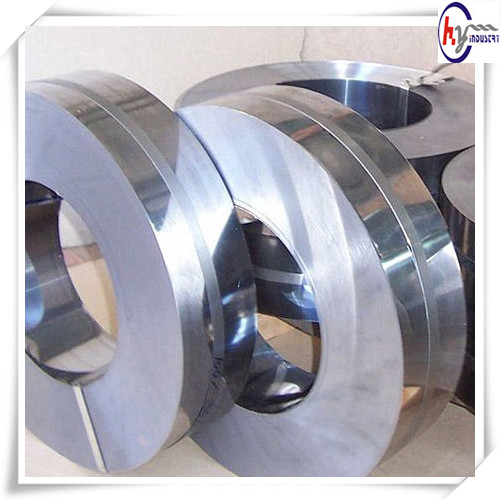

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

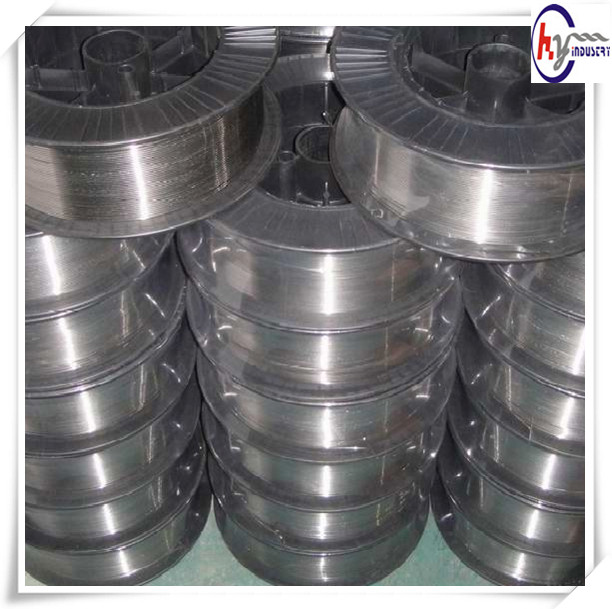

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

Supplier foil、strip、sheet、coil、plate、wire、rod、bar、tube、pipe、flat ribbon、Profiled wire…

BuildingNo.1,Third Industrial District XiTou Village SongGang Town Bao’An District ShenZhen City GuangDong Province China

Qingdao NPA Marketplace Co. Ltd is a foremost manufacturer specialized in centrifugal casting tube and static castings of warmth resistant alloys, which include ethylene cracking furnace tube, reformer furnace tube, CAL(constant annealing traces) &CGL(constant galvanizing traces) furnace roller and radiant tube, glass lehr roller and warmth/have on resistant castings. The annual potential is 9000 tons centrifugal casting tube and 3500 tons static castings (500 tons precision castings).

Internet site: www.npa-china.com