Bottom price for Nickel Alloy Hastelloy X UNS N06002 to Miami Manufacturers

As for competitive prices, we believe that you will be searching far and wide for anything that can beat us. We can state with absolute certainty that for such quality at such prices we are the lowest around for Bottom price for Nickel Alloy Hastelloy X UNS N06002 to Miami Manufacturers, Our company will continue to adhere to the " superior quality, reputable, the user first " principle wholeheartedly. We warmly welcome friends from all walks of life to visit and give guidance, work together and create a brilliant future!

HY HX Material grades and equivalents

Hastelloy X / GB GH3536&GH536/UNS N06002 / SEW VDIUV W.Nr.2.4613 / AFNOR NC22FeD

| HY HX | ||||||||||||||||

| UNS | Trademark | W.Nr | ||||||||||||||

| N06002 | HY HX | 2.4613 | ||||||||||||||

| HY HX Chemical compostion: | ||||||||||||||||

| Alloy | % | Ni | Cr | Fe | C | Mn | Si | Cu | S | B | Ti | P | Co | W | Mo | Al |

| HY HX | Min. | balance | 20.5 | 17 | 0.05 | 0.5 | 0.2 | 8 | ||||||||

| Max. | 23 | 20 | 0.15 | 1 | 1 | 0.5 | 0.015 | 0.01 | 0.15 | 0.025 | 2.5 | 1 | 10 | 0.5 | ||

| HY HX Physical properties: | ||||||||||||||||

| Density | 8.28 g/cm3 | |||||||||||||||

| Melting Point | 1295-1381 ℃ | |||||||||||||||

Hastelloy X Characteristic:

Good oxidation and corrosion resistance. Below 900 °C with middle elevated temperature stress rupture and creep rupture strength; good formability with cold working and hot working and excellent welding fabrication.

Hastelloy X Applied field:

Aero-engine combustion chamber and other parts used at elevated temperatures,long term usage below 900°C,short term usage temperature can reach 1080°C.

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

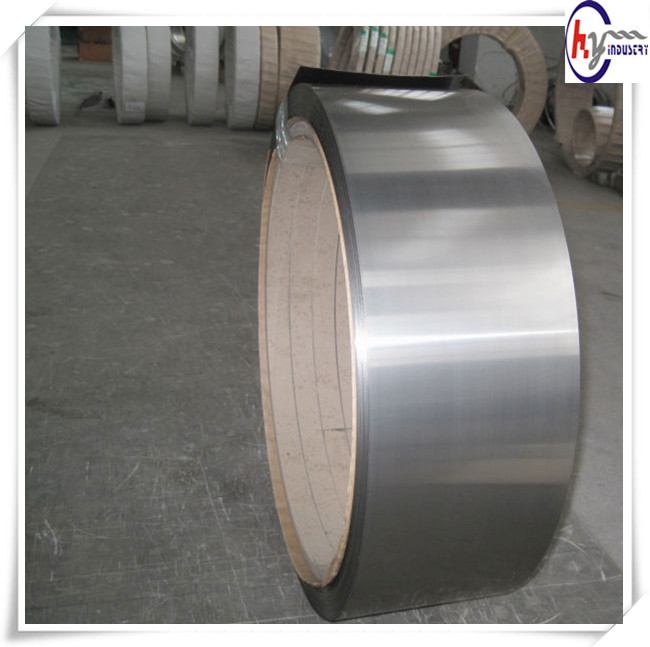

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

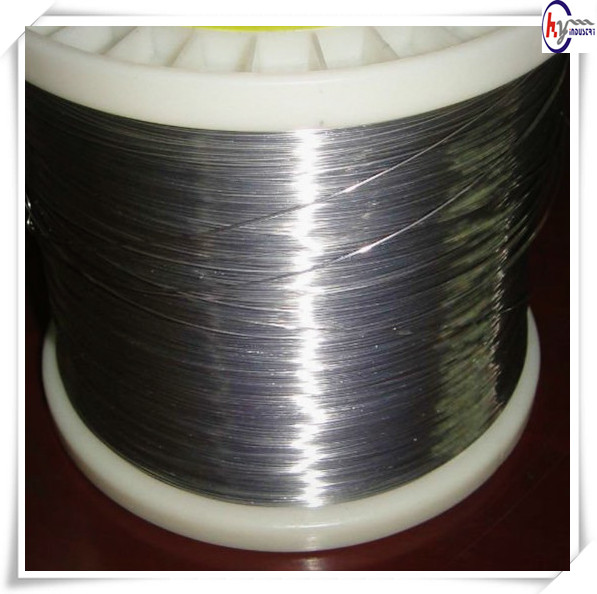

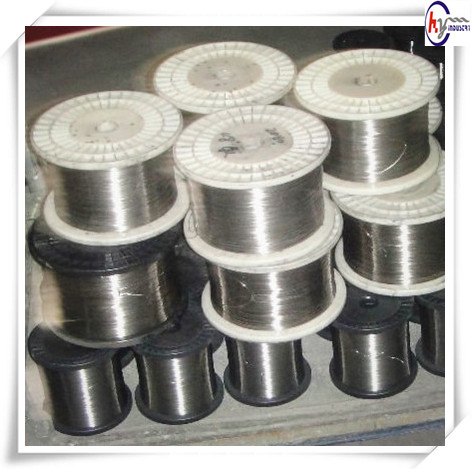

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

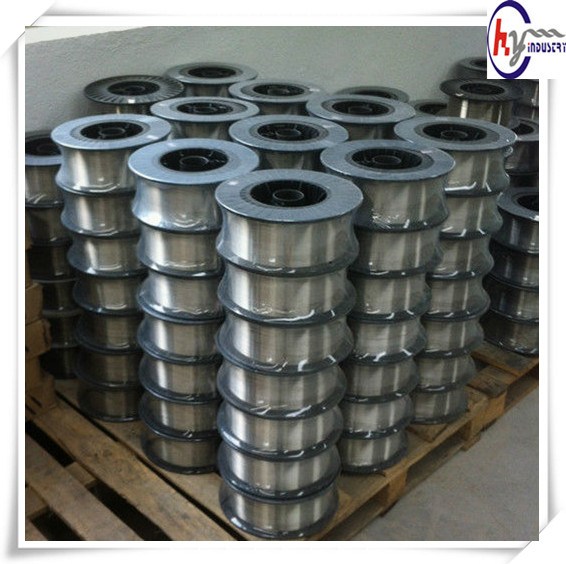

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

The progress of improved metallic resources is a crucial action at the leading edge of science and know-how. Metals offer unrivalled mixtures of houses and reliability at a cost which is economical. They are adaptable mainly because subtle improvements in their microstructure can cause dramatic variations in their houses. For illustration, it is feasible to purchase business steel with a energy as lower as 50 MPa or as large as 5500 MPa. They can be built with a microstructure which is finer than that of carbon nanotubes. An understanding of the progress of microstructure in metals, rooted in thermodynamics, crystallography and kinetic phenomena is crucial for the resources scientist. The bulk of the 1.4 billion tonnes of metals made annually are the outcome of developments within just the last 10 a long time

http://www.msm.cam.ac.british isles/phase-trans/2002/creep.1.html

http://www.weldingtipsandtricks.com/metals-and-how-to-weld-nickel.html

How to weld nickel alloys like hastelloy, inconel, etc. Nickel alloys have a low thermal conductivity and so limiting heat input and using lower amperage than would be used for stainless is one key to making good nickel alloy welds.