Cheap price Heat Resistant Wire 1Cr13Al4 Fe-Cr-Al Alloy wire Manufacturer in Gambia

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Cheap price Heat Resistant Wire 1Cr13Al4 Fe-Cr-Al Alloy wire Manufacturer in Gambia, "Passion, Honesty, Sound service, Keen cooperation and Development" are our goals. We are here expecting friends all over the world!

HY 1134 Material grades and equivalents

1Cr13Al4

HY 1134 Grade property performance

|

Grade property performance |

HY 1134 |

|

|

% Main Chemical Composition |

Cr |

12~15 |

|

Al |

4~6 |

|

|

Fe |

Balance |

|

|

Mn |

≤0.7 |

|

|

Nb |

— |

|

|

℃ Max contimnous service Temp. of element |

950 |

|

|

Resistivity mm2/m |

1.25±0.08 |

|

|

10-5/℃ Temp coeff of resistance |

15 |

|

|

g/cm3 Density |

7.4 |

|

|

Melting point≈ ℃ (approxi) |

1450 |

|

|

Tensile strength N/mm2 |

588~735 |

|

|

% Elongation |

>16 |

|

|

% Reducation of Area |

65~75 |

|

|

Hardness(HB) |

200~260 |

|

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

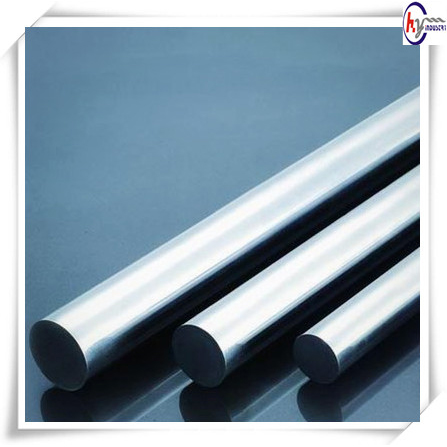

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

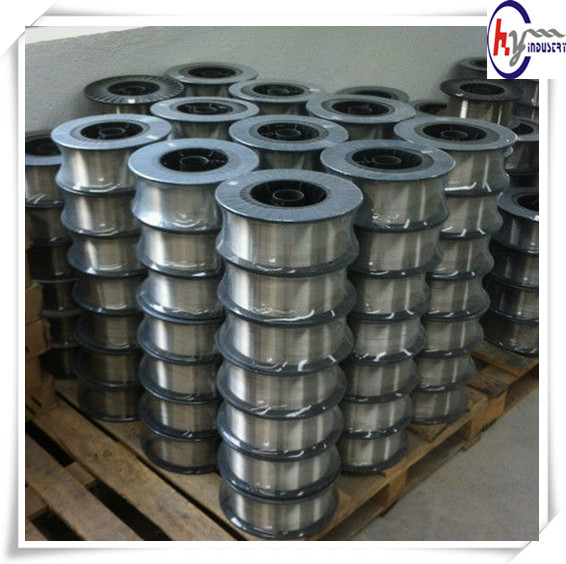

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

Turning insert brochures are obtainable for obtain at http://www.mitsubishicarbide.com/mmus/en/products/catalog/turning.html

Mitsubishi offers particular J-Series breakers and micro-grain grades for turning hard to minimize supplies. Mitsubishi breakers for warmth resistant alloys include the FJ (mild slicing), MJ (medium slicing) and GJ (medium to semi-weighty slicing). The presenting is concluded with the addition of the twin rake MS (medium slicing) breaker and spherical RCMX insert also for medium slicing. FJ and MJ collection insert are obtainable in G Class tolerances for applications that need a sturdy sharp slicing edge. For Titanium and non-ferrous supplies, the polished FJ-P/MJ-P edition is obtainable.

The FJ’s sharp slicing geometry is obtainable in common .002, .004, .008 and .016″ software nose radius. Although the MS and MJ software nose radius begins at .016 and the GJ at .031″ and up. Our warmth resistant alloy breakers are obtainable in a vast range of micro-grain grades particularly design for this market place phase. Our micro-grain grades are obtainable non-coated or topped off with PVD/CVD coatings and edge preparations to suit to the insert software range.

Out there uncoated grades are: RT9005, RT9010, TF15 and Hti10.

Our Miracle Coating (Al, Ti)N PVD grades are: VP05RT, VP10RT and VP15TF.

CVD coated US905 is design to deliver unequalled dress in resistance in stable higher velocity applications. The close microstructure of US905 CVD coatings limits insert flank and deal with dress in at higher speeds when in contrast to other merchandise. US905 has the best hardness cemented carbide substrate appropriate for CVD Coating.

To see all Mitsubishi Cutting Device products channels on YouTube, comply with url:

http://www.youtube.com/user/mitsubishicarbide/video clips?view=one

Or

Go to 1 of our products precise channels below:

The Cutting Edge: http://www.youtube.com/playlist?list=PL1CEA67C978F3029D&feature=view_all

Turning & Dull Channel: http://www.youtube.com/playlist?list=PL0D406ECCFFF53995&feature=view_all

Milling Channel: http://www.youtube.com/playlist?list=PL648BF1B051AE20F0&feature=view_all

Drilling Channel: http://www.youtube.com/playlist?list=PL6960075BD195101A&feature=view_all

Grooving Channel: http://www.youtube.com/playlist?list=PL3AD4CC3127719A38&feature=view_all

Swiss Tooling Channel: http://www.youtube.com/playlist?list=PL0FBAAF2F0230343C&feature=view_all

CBN Channel: http://www.youtube.com/playlist?list=PLBB88F97F9A2B5376&feature=view_all

Strong Carbide Close Mill Channel: http://www.youtube.com/playlist?list=PL7A1549BEF477EDDB&feature=view_all

Mitsubishi Elements Usa – Cutting Applications, Social Media Websites:

Fb: http://www.facebook.com/MitsubishiMaterials.US.CuttingTools

Twitter: http://twitter.com/#!/MMUSCuttingTool

YouTube: http://www.youtube.com/user/mitsubishicarbide

Supplemental Means:

Encounter Mitsubishi Carbide’s Patented On the internet Catalog with downloadable CAD information http://www.mitsubishicarbide.internet/mmus/en/catalogue/index.html

Extra Mitsubishi Cutting Device Films can be discovered at http://www.mitsubishicarbide.com/mmus/en/products/online video/index.html

Issues remember to speak to:

Complex Guidance at one-800-486-2341

Or

E mail MarketingServices@mmus.com

Protected specialized inquires can be submitted to Mitsubishi Elements at https://www.mitsubishicarbide.com/mailform/mmus/en/literature/sort.html

Thank you for using the time to view this online video and remember to take a look at Mitsubishi Elements Usa at http://www.mmus.com

Riporto(placcatura)con filo Nimonic 80 dia. one.2 eseguito con inverter multiprocesso Weldtronic Synertech 8004 Digit in pulsato sinergico.

NB .Il lampeggio dell’arco è presente solo nella ripresa effettuata dalla fotocamera digitale usata probabilmente a causa di interferenza con l’intenso arco luminoso.

Details: belda1@tiscali.it