Cheap price Nickel Alloy Incoloy 825 UNS N08825 Export to Greek

Our company puts emphasis on the management, the introduction of talented personnel, and the construction of staff building, trying hard to improve the quality and liability consciousness of staff members. Our company successfully attained IS9001 Certification and European CE Certification of Cheap price Nickel Alloy Incoloy 825 UNS N08825 Export to Greek, winning customers' trust is the gold key to our success! If you are interested in our products, please feel free to visit our web site or contact us.

HY 825

Material grades and equivalents

Incoloy 825/GB NS1402/UNS N08825/SEW VDIUV W.Nr.2.4858 NiCr21Mo/BS NA16/AFNOR NC21FeDU

HY 825Chemical composition

|

Alloy |

% |

Ni |

Cr |

Fe |

C |

Mn |

Si |

Cu |

Mo |

Al |

Ti |

P |

S |

|

825 |

Min. |

38 |

19.5 |

balance |

1.5 |

2.5 |

1.0 |

0.6 |

|||||

|

Max. |

46 |

23.5 |

balance |

0.05 |

1 |

0.5 |

3 |

3.5 |

0.2 |

1.2 |

0.02 |

0.03 |

HY 825Physical properties

|

Density |

8.1 g/cm³ |

|

Melting point |

1370-1400°C |

HY 825Alloy mi nimum mechanical properties in the room temperature

|

Alloy state |

Tensile strength |

Yield strength |

Elongation |

Brinell hardness |

|

825 |

550 |

220 |

30 |

≤200 |

Characteristic as below

1. Good stress corrosion cracking resistance performance

2. Good resistance for pitting and crevice corrosion performance

3. Good anti-oxidation and non-oxidzing heat acid performance

4. Good mechanical performance in both room temperature and up to 550°C

5. Have the pressure vessel authenticate when manufacture temperature up to 450°C

HY 825Metallurgical structure

825 is the face-centered cubic lattice structure.

HY 825Corrosion resistance

825 is an all-purpose project alloy, have good corrosion resistance of the acid and alkali metal property in both oxidation and reduction environments. High nickel content made it with effective stress corrosion cracking resistance performance. 825 have excellent corrosion resistance in different kinds of media, such as sulfuric acid, phosphoric acid, nitric acid and organic acid, alkali metal such as sodium hydroxide, potassium hydroxide, and hydrochloric acid. A variety of media corrosion of nuclear-burning dissolver show 825 high integrated prpperty, like sulfuric acid, nitric acid and potassium hydroxide are all dealing in a same device.

HY 825Application field

825widely use in many kinds of industry field that the working temperature no more than 550°C.

HY 825Typical application field

1. Sulfuric acid factory usage for heating pipe, container, basket, chain and so on.

2. Cooling heat exchanger, marine product pipeline system and gas pipeline of acidic environment.

3. Heat exchanger, steam machine, washing, impregnation pipe, etc. for phosphoric acid produce

4. Oil refining in the air heat exchanger

5. Food project

6. Chemical process

7. Application of high pressure oxygen flam-retardant alloy

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

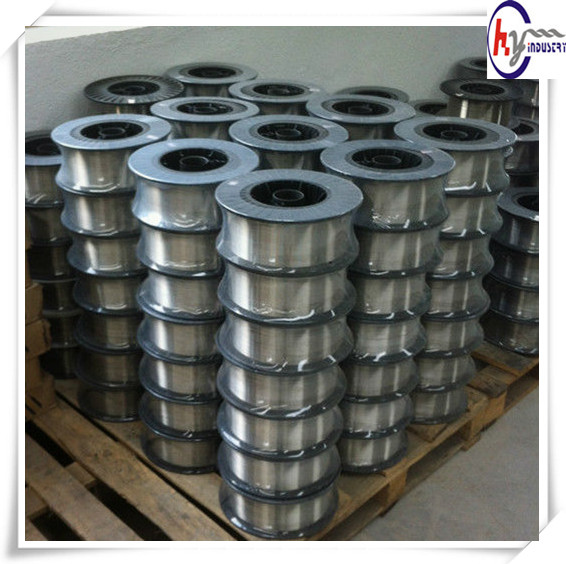

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

Substantial Temp Nickel Centered & Tremendous Alloys – Mechanical Homes Inconel Round Bar, Plate Sheet Offer – Inconel is designed of Mostly Nickel and a number of other aspects. The origin coming from Supernovas. Inconel is a Tremendous Alloy and Michlin Metals sells Inconel Round Bar, Hex Bar, Flat Bar, Plate, Sheet, Tube and Pipe.

The progress of improved metallic resources is a crucial action at the leading edge of science and know-how. Metals offer unrivalled mixtures of houses and reliability at a cost which is economical. They are adaptable mainly because subtle improvements in their microstructure can cause dramatic variations in their houses. For illustration, it is feasible to purchase business steel with a energy as lower as 50 MPa or as large as 5500 MPa. They can be built with a microstructure which is finer than that of carbon nanotubes. An understanding of the progress of microstructure in metals, rooted in thermodynamics, crystallography and kinetic phenomena is crucial for the resources scientist. The bulk of the 1.4 billion tonnes of metals made annually are the outcome of developments within just the last 10 a long time

http://www.msm.cam.ac.british isles/phase-trans/2002/creep.1.html