Cheap price Nickel Alloy Inconel 625 UNS N06625 Wholesale to Turkmenistan

As for competitive prices, we believe that you will be searching far and wide for anything that can beat us. We can state with absolute certainty that for such quality at such prices we are the lowest around for Cheap price Nickel Alloy Inconel 625 UNS N06625 Wholesale to Turkmenistan, items won certifications with the regional and international primary authorities. For far more detailed information, please contact us!

HY 625 Material grades and equivalents

Inconel 625/ GB NS336 / UNS N06625/ SEW VDIUV W.Nr.2.4856 NiCr22Mo9Nb / BS NA 12 / AFNOR NC22DNB

HY 625 Chemical composition

|

Alloy |

% |

Ni |

Cr |

Mo |

Nb+N |

Fe |

Al |

Ti |

C |

Mn |

Si |

Cu |

P |

S |

|

625 |

Min. |

58 |

20 |

8 |

3.15 |

|||||||||

|

Max. |

23 |

10 |

4.15 |

5 |

0.4 |

0.4 |

0.1 |

0.5 |

0.5 |

0.5 |

0.015 |

0.015 |

HY 625 Pysical properties

|

Density |

8.4 g/cm3 |

|

Melting point |

1290-1350°C |

HY 625 Alloy m inimum mechanical properties in the room temperature

|

Alloy state |

Tensile strength |

Yield strength |

Elongation A 5 % |

Brinell hardness |

|

625 |

760 |

345 |

30 |

≤220 |

Characteristic as below

1. Excellent corrosion resistance of different kinds of media in both oxidation and reduction environments.

2. Excellent resistance of pitting and crevice corrosion, and won’t happen stress corrosion cracking because of chloride.

3.Excellent resistance of the inorganic acid corrosion performance, such as nitric acid, phosphoric acid, sulfuric acid, hydrochloric acid and the mixture of sulfuric acid and hydrochloric acid.

4. Excellent corrosion resistance of different kinds of inorganic acid mixture performance.

5. Good corrosion resistance of a variety of concentrations of hydrochloric acid when the temperature up to 40°C .

6. Good machining and welding, no weld cracking sensitivity.

7. Have pressure vessel authentication for the wall temperature between -196 ~ 450°C .

8. Apply for the highest standard lever VII of acidic environment by the NACE ( MR-01-75) authorized.

HY 625 Corrosion resistance

625 own a very good corrosion resistance in many media, especially with excellent resistance to pitting, crevice corrosion, intercrystalline corrosion, and erode in oxide, also good resistance to inorganic acid corrosion, such as nitric acid, phosphoric acid, sulfuric acid and hydrochloric acid. 625 can resist the alkali and organic acid corrosion in the oxidation and reduction environment. Effect resists the chloride reduction stress corrosion cracking. Normally no corrosion in the sea-water and industry environments since high corrosion resistance to the sea-water and salting liquid,as well as in high temperature, without sensitivity during welding. 625 have the resistance to oxidation and carbonizing in the static and cycle environments, also hacve the resistance the chlorine corrosion.

HY 625 Application field

Soften annealing low carbon alloy 625 widely used in the chemical process industry, good corrosion resistance and high strength made it an good choice for structural parts. 625 have application in sea-water for local mechanical stress attach.

HY 625 Typical application field as below

1 .The Organic chemical process parts contains chloride, especially in the use of acid chloride catalyst.

2. The digester and bleacherin the use of paper pulp and paper making industry.

3.Absorption tower, re-heater,gas import board, fan, blender, fair water fin, flue and so on for using in flue gas desulfurization system.

4. The equipment and parts in the use of acidic gas environments.

5. Acetic acid and anhydride reaction generator

6. Sulfur acid cooling

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

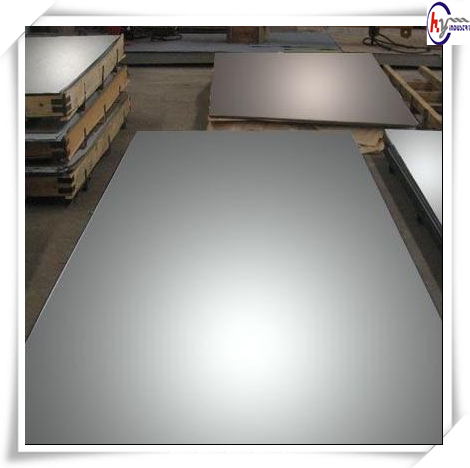

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

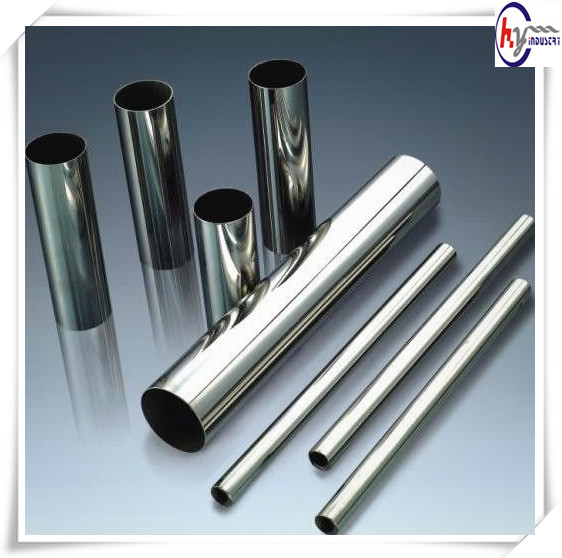

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

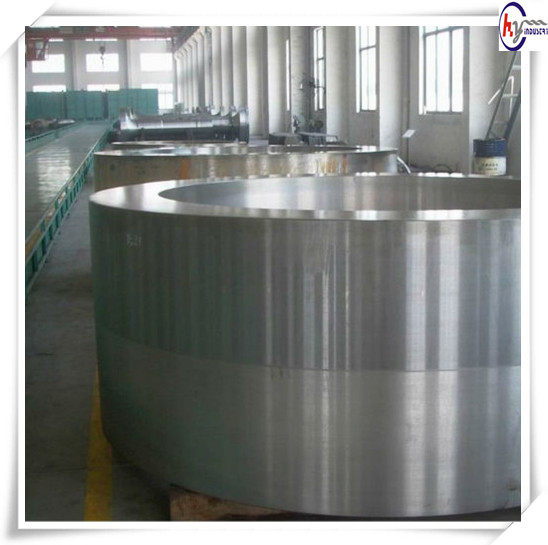

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

Experimentální odlévání monelu na katedře strojírenské technologie při TU v Liberci – Monel je slitina niklu a mědi. Název Monel je registrován jako trademark americké firmy Specific Metals Corporation. Monel vyrobil v roce 1901 Robert Crooks Stanley, slitinu pojmenoval po tehdejším prezidentu firmy Ambrose Monellovi.

Monel vykazuje výborné mechanické vlastnosti a chemickou odolnost v náročném prostředí, např. v dlouhodobém kontaktu se slanou vodou, ale i v chemickém průmyslu. Často bývá využit tam, kde již nedostačují vlastnosti nerezových ocelí.

Monel is a group of nickel alloys, largely composed of nickel (up to sixty seven%) and copper, with tiny quantities of iron, manganese, carbon, and silicon. More powerful than pure nickel, Monel alloys are resistant to corrosion by quite a few agents, like promptly flowing seawater. They can be fabricated quickly by very hot- and chilly-working, machining, and welding.[2]

Monel was made by David H. Browne, main metallurgist for Global Nickel Co. Monel alloy four hundred is a binary alloy of the identical proportions of nickel and copper as is found naturally in the nickel ore from the Sudbury (Ontario) mines and is thus thought of a puritan alloy. Monel was named following business president Ambrose Monell, and patented in 1906.[three] Just one L was dropped, for the reason that loved ones names were being not allowed as trademarks at that time.[one] The title is now a trademark of Specific Metals Corporation.

Visit my site for additional Recommendations, Films, Do it yourself assignments and additional:

http://www.mjlorton.com/

—————————–Click “Display additional”—————————————

A information on making use of the correct applications to crimp connectors, strip wire and implement warmth shrink.

You should guidance my information generation by making use of my Amazon Retail store:

http://astore.amazon.com/m0711-twenty

Purchase these applications and connectors below: http://astore.amazon.com/m0711-twenty?node=ten&site=one

——————— Click “Display additional” ——————————-

My site and forum:- http://www.mjlorton.com

Donations and contributions:- http://www.mjlorton.com

My techie channel MJLorton – Solar Power and Digital Measurement Products – http://www.youtube.com/MJLorton

My Techie Amazon Retail store: http://astore.amazon.com/m0711-twenty

My other channel VBlogMag – For nearly any matter beneath the sun! – http://www.youtube.com/VBlogMag

My VBlogMag Amazon Retail store: http://astore.amazon.com/vblogmag-twenty

———————————————————————–

=================================================

Online video sponsor, Pass Ltd – their internet websites:

http://www.tester.co.united kingdom/?cmid=QmhzQjcxYjVlc1E9&afid=bFcwbzliNzVDc289&ats=K2EyUjZNTDh3UTA9 – Examination Products and Examination-meter suppliers and

http://www.calibrate.co.united kingdom/?cmid=QmhzQjcxYjVlc1E9&afid=bFcwbzliNzVDc289&ats=S3Yxd2tOMjVISzA9 – Calibration and support of exam tools

=================================================

Additional dialogue and link to NASA information below:

http://mjlorton.com/forum/index.php?matter=244.

In this online video:

* Deciding upon the correct wire gauge (AWG – American Wire Gauge) for the crimp connector.

* Employing the correct applications to strip the insulation from the wire.

* The correct way to insert the wire into the crimp connector

* Employing the correct crimp applications to crimp the connector

* How to implement warmth shrink accurately to the wire and crimp connector.