Cheap PriceList for Iron Alloy Precision Alloy Invar 36 UNS K93600 to Malta Factory

The customer satisfaction is our primary target. We uphold a consistent level of professionalism, quality, credibility and service for

Cheap PriceList for Iron Alloy Precision Alloy Invar 36 UNS K93600 to Malta Factory, With the aim of "compete with good quality and develop with creativity" and the service principle of "take customers' demand as orientation", we will earnestly provide qualified products and good service for domestic and international customers.

HY I36 Material grades and equivalents

GB 4J36/UNS K93600/AISI/ASTM Invar36/W.Nr.1.3912/Pernifer 36

Chemical composition

|

Alloy |

% |

Ni |

Cr |

Fe |

C |

Mn |

Si |

Co |

Mo |

P |

S |

|

HY I36 |

Min. |

35 |

Balance |

||||||||

|

Max. |

38 |

0.5 |

0.1 |

0.06 |

0.35 |

1.0 |

0.5 |

0.02 |

0.025 |

Physical properties

|

Density |

8.1 g/cm3 |

|

Melting point |

1430 °C |

Mechanical properties in the room temperature

|

Alloy state |

Tensile strength Rm N/mm2 |

Yield strength RP0.2N/mm2 |

Elongation A5 % |

Brinell hardness HB |

|

HY I36 |

490 |

240 |

42 |

≤200 |

Characteristic

HY I36 alloy is a special ultra-low coefficient of heat expansion of low-iron-nickel alloy. One of carbon and manganese element of control is very important. Cold deformation can reduce the coefficient of thermal expansion, in particular within the framework of the heat treatment temperature coefficient of thermal expansion will enable stabilization. Has the following characteristics:

1.Has very low coefficient of heat expansion between the temperature of -250°C and 200°C.

2.Good toughness and plastic

Metallurgical structure

HY I36 is the face centered cubic lattice structure

Corrosion resistance

HY I36 has corrosion resistance in the dry air of room temperature. In other harsh environments, such as the humid air, there may be corrosion (rust).

Applied field

HY I36 suit for need to apply ultra-low coefficient of heat expansion environment. Typical applications are as follows:

1.Liquefied gas production, storage and transport

2.The measurement and control instruments work temperature lower than 200°C, such as temperature regulating device

3.Metals and other materials use the screw connector bush

4.Bimetal and bimetallic temperature controller

5.Film framework

6.Shadow mask

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

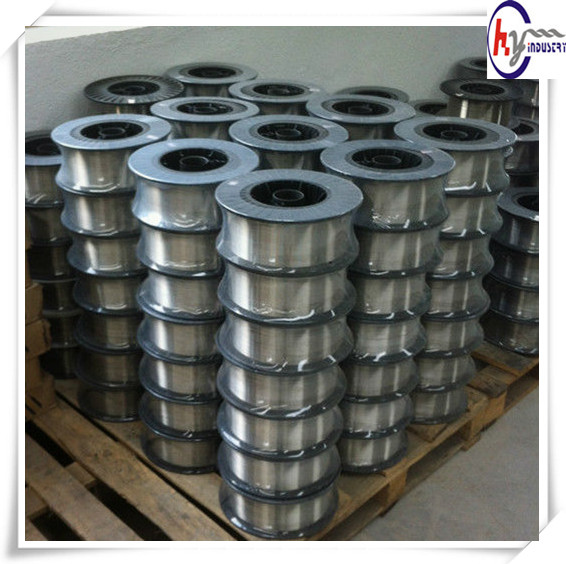

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

Provider foil、strip、sheet、coil、plate、wire、rod、bar、tube、pipe、flat ribbon、Profiled wire…

BuildingNo.one,3rd Industrial District XiTou Village SongGang City Bao’An District ShenZhen Town GuangDong Province China

Experimentální odlévání monelu na katedře strojírenské technologie při TU v Liberci – Monel je slitina niklu a mědi. Název Monel je registrován jako trademark americké firmy Specific Metals Corporation. Monel vyrobil v roce 1901 Robert Crooks Stanley, slitinu pojmenoval po tehdejším prezidentu firmy Ambrose Monellovi.

Monel vykazuje výborné mechanické vlastnosti a chemickou odolnost v náročném prostředí, např. v dlouhodobém kontaktu se slanou vodou, ale i v chemickém průmyslu. Často bývá využit tam, kde již nedostačují vlastnosti nerezových ocelí.

Monel is a group of nickel alloys, largely composed of nickel (up to sixty seven%) and copper, with tiny quantities of iron, manganese, carbon, and silicon. More powerful than pure nickel, Monel alloys are resistant to corrosion by quite a few agents, like promptly flowing seawater. They can be fabricated quickly by very hot- and chilly-working, machining, and welding.[2]

Monel was made by David H. Browne, main metallurgist for Global Nickel Co. Monel alloy four hundred is a binary alloy of the identical proportions of nickel and copper as is found naturally in the nickel ore from the Sudbury (Ontario) mines and is thus thought of a puritan alloy. Monel was named following business president Ambrose Monell, and patented in 1906.[three] Just one L was dropped, for the reason that loved ones names were being not allowed as trademarks at that time.[one] The title is now a trademark of Specific Metals Corporation.