Cheap PriceList for Titanium alloy 6Al-4V UNS R56400 Export to Durban

abide by the contract", conforms to the market requirement, joins in the market competition by its high quality as well as provides more comprehensive and excellent service for clients to let them become big winner. The pursue of the company, is the clients' satisfaction for Cheap PriceList for Titanium alloy 6Al-4V UNS R56400 Export to Durban, Competitive price with high quality and satisfying service make us earned more customers.we wish to work with you and seek common development.

HY Titanium 6-4 Material grades and equivalents

6-4 Titanium, 6-4, Ti 6-4, UNS R56400

Introduction

HY Titanium 6-4 is the most widely used of all the alpha-beta titanium alloys. It is typically used in the annealed condition, at service temperatures through 750°F. However it may be heat treated for high strength in sections under 4″ thick. Hardenability is limited and sections over one inch may not develop full properties. HY Titanium 6-4 is welded with matching or with ELI filler wire.

Mill anneal: 1300-1450°F 2 hours, air cool. Recrystallization anneal bar for better ductility and fatigue strength, 1750°F 2 hours, furnace cool.

For maximum fracture toughness and SCC resistance: Beta anneal 1950°F 1-2 hours, water quench. Then age 1150-1300°F 2 to 4 hours, air cool.

For maximum strength: solution-treated and aged (STA) condition is: For sheet, 1675-1725°F 5 to 25 minutes, water quench. Age 975°F 4 to 6 hours, air cool. For bars and forgings, 1675-1725°F 1 hour, water quench. Age 975-1025°F 3 hours, air cool.

For increased fracture toughness, but lower tensile strength: precipitation treat (overage) 1150-1250°F 4 hours, air cool. Stress relief annealing is commonly 1000-1200°F 1 to 4 hours, air cool.

HY Titanium 6-4 is resistant to general corrosion but may be quickly attacked by environments that cause breakdown of the protective oxide. These include hydrofluoric (HF), hydrochloric (HCl), sulfuric and phosphoric acids. Inhibitors may help for the last four but not for HF. HY Titanium 6-4 resists attack by pure hydrocarbons, and most chlorinated and fluorinated hydrocarbons (provided water has not caused formation of small amounts of HCl and HF).

HY Titanium 6-4 is susceptible to chloride stress corrosion cracking (SCC), although being among the better of the titanium alloys in this regard. For marine environments silver plated bolts are not used, as silver bonds easily with chlorine in this environment. HY Titanium 6-4 is also susceptible to SCC in environments such as methyl alcohol, red fuming HNO3, and N2O4. In the case of red fuming nitric acid, the problem is limited to environments containing less than 1.5% water, or more than 6% NO2. Failure in N2O4 has occurred when oxygen and chlorides were present as impurities.

Chemistry Composition

|

|

Al |

V |

C |

N |

O |

H |

Fe |

Y |

Others, |

Others, |

Ti |

|

MIN |

5.5 |

3.5 |

– |

– |

– |

– |

– |

– |

– |

– |

– |

|

MAX |

6.75 |

4.5 |

0.08 |

0.05 |

0.2 |

0.0125 |

0.3 |

0.005 |

0.1 |

0.4 |

Balance |

Features

- High strength to 600°F

- Excellent general corrosion resistance

- High strength-to-weight ratio

Applications

- Turbine blades, discs and rings

- Aircraft structural components

- Weapons structural components

- Fasteners

- Medical and dental implants

- Hand tools

- Sporting equipment

- Chemical process equipment

Physical Properties

Density: 0.160 lb/inch3

Melting Range: 2929 – 3020°F

Beta Transus: 1825± 25°F

|

Temperature, °F |

70 |

200 |

400 |

600 |

|

Coefficient of Thermal Expansion, in/in°F x 10-6 |

- |

5.3 |

5.4 |

5.5 |

|

Thermal Conductivity, |

4.0 |

4.3 |

5.2 |

6.1 |

|

Modulus of Elasticity, |

16.7 |

16.0 |

15.0 |

14.0 |

Mechanical Properties

Specified, AMS 4911, annealed sheet & plate

|

|

Anneal 1300°F, Air Cool |

Anneal 1300°F, Solution anneal 1750°F , Age 1000°F |

|

Ultimate Tensile Strength, ksi |

138-155 |

150-172 |

|

0.2% Yield Strength, ksi |

128-147 |

137-156 |

|

Elongation, % |

15-20 |

15-17 |

|

Reduction of Area, % |

38-51 |

41-46 |

Typical Tensile Strength and Fracture Toughness, Various Heat Treatments for Flat-rolled Products (MCIC-HB-02 1985 reprint)

|

|

0.2% Yield Strength, ksi |

Fracture Toughness K1C, ksi √in |

|

Annealed |

132 |

128 |

|

Beta Annealed (plate) |

131 |

134 |

|

Beta STA 1250°F b |

128 |

150 |

|

Beta STA 1000°F b |

143 |

120 |

|

STA 1250°Fc |

137 |

105 |

|

STA 1000°Fc |

159 |

80 |

(a) Directional variations,

(b) Beta heat treated followed by solution treating and overaging 1250˚F, or aging 1000˚F

(c) Solution treating and overaging 1250˚F, or aging 1000˚F

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

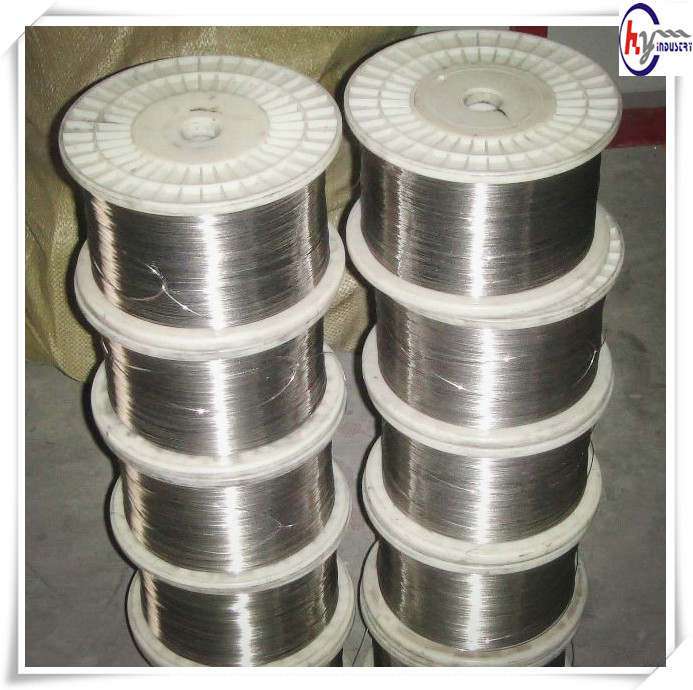

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

Check out additional TIG Welding Video clips from Weld.com:

http://www.weld.com/index.php/Mr-Tig-Blog/

Subscribe on YouTube and Never ever Miss a Video!

http://www.youtube.com/channel/UCM0kHJXSHR1k1wtLuliKmHg?sub_confirmation=one

Pay a visit to the Welding Discussion board to Carry on the Dialogue and Compete in Month to month Contests!

http://www.weld.com/index.php/Weekend-Warrior-Welding-Discussion board/groups.html

Fb: https://www.fb.com/WeldDotCom

Twitter: https://twitter.com/WeldDotCom

—————————————————————————–

Weld.com welding films are a collection of welding displays that are loaded with welding strategies, tricks and hints that will support you drop that perfect bead each individual time! Whether you are making an attempt to become far better in the locations of TIG Welding, MIG Welding, Adhere Welding or Slicing Weld.com has what you will need. All films are shot from “guiding the hood” so you can get the welders standpoint. In addition to exhibiting you how to weld, many periods we will clearly show you popular issues and how to steer clear of them.

New episodes each individual Friday!

Early launch on the discussion board!

To comprehend that the utilizes for particular metals relate to their unique qualities.

To comprehend that the qualities of metals can be improved by generating alloys.

To recall that some of the hottest alloys, called ‘Smart Alloys’ can change their qualities on demand from customers.

Duplicate the table beneath. Working with a companion, entire as a great deal of the table as you can.

Very low density, powerful, resistant to corrosion, very good conductor of energy

Good conductor of energy, resistant to corrosion, quickly formed, flexible

Shiny, very resistant to corrosion, very unreactive, soft, quickly formed

Extremely powerful, very dense.

Lightweight buildings, plane, drinks cans, higher voltage cables.

Electrical wiring, h2o pipes.

Jewelry.

Substantial buildings and significant responsibility engineering these as bridges, trains, autos and so forth.

In pure metals the atoms prepare them selves closely collectively into regular styles. This tends to make them dense and also presents them numerous of their other helpful qualities.

The layer arrangement of the atoms permits the metals to transform form if a pressure is utilized. The layers can slip around every other.

This can be helpful if you want to form the steel but not so helpful if you want it to resist the pressure and be powerful.

By mixing two or additional metals collectively the regular arrangement of the atoms is disrupted. This stops the atoms forming layers and tends to make it harder for the atoms to slide around every other. The alloy is more robust than the pure metals.

Steel B

Steel A

Steel is an alloy. Pure iron is not powerful enough to be employed in buildings. Steel contains a smaller amount of carbon. This disrupts the layers of atoms in the steel and improves the toughness of the steel considerably.

Despite the fact that it is very powerful metal will corrode (rust) quickly and it has to be regularly protected from the consequences of h2o and air.

Stainless metal is an alloy that contains other metals these as Nickel and Chromium. Stainless metal has the toughness of metal mixed with the corrosion resistance of nickel and the shininess of chromium. This tends to make it a helpful materials in programs exactly where you will need toughness mixed with magnificence and corrosion resistance..

Clever Alloys

These are alloys that can ‘remember’ their primary form. If they are deformed they can return to their primary form.

Condition memory glasses

Condition memory Stent to continue to keep a blocked blood vessel open

Metals, Alloys and Clever Alloys

Finding out Objectives:

To comprehend that the utilizes for particular metals relate to their unique qualities.

To comprehend that the qualities of metals can be improved by generating alloys.

To recall that some of the hottest alloys, called ‘Smart Alloys’ can change their qualities on demand from customers.