Cheapest Price Nickel Alloy Inconel 617 UNS N06617 to Ireland Factory

We are proud of the high customer satisfaction and wide acceptance due to our persistent pursuit of high quality both on product and service for Cheapest Price Nickel Alloy Inconel 617 UNS N06617 to Ireland Factory, With the aim of "compete with good quality and develop with creativity" and the service principle of "take customers' demand as orientation", we will earnestly provide qualified products and good service for domestic and international customers.

HY617 Material grades and equivalents

Inconel 617/ UNS N07617 / SEW VDIUV W.Nr.2.4663 NiCr23Co12Mo / AFNOR NC22KDA

HY 617 is a solid-solution, strengthened, nickel-chromium-cobalt- molybdenum alloy with an exceptional combination of high-temperature strength and oxidation resistance. The alloy also has excellent resistance to a wide range of corrosive environments, and it is readily formed and welded by conventional techniques.

The combination of high strength and oxidation resistance at temperatures over 1800°F (980°C) makes HY617 an attractive material for such components as ducting, combustion cans, and transition liners in both aircraft and land-based gas turbines.

HY 617 Chemical composition:

|

Alloy |

% |

Ni |

Cr |

Fe |

C |

Mn |

Si |

Mo |

Co |

Al |

Ti |

P |

S |

|

617 |

Min |

20 |

0.05 |

8 |

10.0 |

0.6 |

0.2 |

||||||

|

Max |

Rest |

23 |

2.0 |

0.1 |

0.7 |

0.7 |

10.0 |

13.0 |

1.5 |

0.6 |

0.012 |

0.008 |

HY 617 Physical properties:

|

Density |

8.4 g/cm³ |

|

Melting Point |

1330-1380℃ |

Corrosion Resistance

elevated temperatures, those elements cause the formation of a thin, subsurface zone of oxide particles.

The zone forms rapidly upon exposure to high temperatures until it reaches a thickness of 0.001 to 0.002

in. (0.025 to 0.05 mm). The oxide zone provides the proper diffusion conditions for the formation of a

protective chromium oxide layer on the surface of the metal. It also helps to prevent spalling of the

protective layer.

HY 617 has excellent resistance to carburization. Table 9 compares alloy 617 and some other

carburization-resistant alloys in a gaseous carburizing environment at 2000°F (1095°C). The weight-gain

measurements indicate the amount of carbon absorbed during the test period. The composition of INCONEL alloy 617 includes substantial amounts of nickel, chromium, and aluminum for

a high degree of resistance to oxidation and carburization at high temperatures. Those elements, along

with the molybdenum content, also enable the alloy to withstand many wet corrosive environments.

Heat Treatment

HY 617 is normally used in the solutionannealed condition. That condition provides a coarse grain

structure for the best creep-rupture strength. It also provides the best bend ductility at room temperature. Solution

annealing is performed at a temperature of 2150°F (1175°C)for a time commensurate with section size.

Cooling should be by water quenching or rapid air cooling.

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

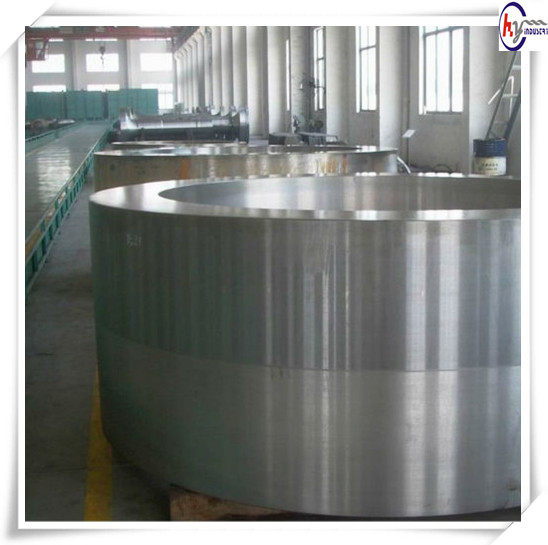

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

High successful HRSA turbine blade roughing on Starrag LX 051

- Materials technical specs: Nimonic 80A, NiCr20TiAl (2.4952)

- MMR: sixteen.nine cm3/min

To comprehend that the utilizes for particular metals relate to their unique qualities.

To comprehend that the qualities of metals can be improved by generating alloys.

To recall that some of the hottest alloys, called ‘Smart Alloys’ can change their qualities on demand from customers.

Duplicate the table beneath. Working with a companion, entire as a great deal of the table as you can.

Very low density, powerful, resistant to corrosion, very good conductor of energy

Good conductor of energy, resistant to corrosion, quickly formed, flexible

Shiny, very resistant to corrosion, very unreactive, soft, quickly formed

Extremely powerful, very dense.

Lightweight buildings, plane, drinks cans, higher voltage cables.

Electrical wiring, h2o pipes.

Jewelry.

Substantial buildings and significant responsibility engineering these as bridges, trains, autos and so forth.

In pure metals the atoms prepare them selves closely collectively into regular styles. This tends to make them dense and also presents them numerous of their other helpful qualities.

The layer arrangement of the atoms permits the metals to transform form if a pressure is utilized. The layers can slip around every other.

This can be helpful if you want to form the steel but not so helpful if you want it to resist the pressure and be powerful.

By mixing two or additional metals collectively the regular arrangement of the atoms is disrupted. This stops the atoms forming layers and tends to make it harder for the atoms to slide around every other. The alloy is more robust than the pure metals.

Steel B

Steel A

Steel is an alloy. Pure iron is not powerful enough to be employed in buildings. Steel contains a smaller amount of carbon. This disrupts the layers of atoms in the steel and improves the toughness of the steel considerably.

Despite the fact that it is very powerful metal will corrode (rust) quickly and it has to be regularly protected from the consequences of h2o and air.

Stainless metal is an alloy that contains other metals these as Nickel and Chromium. Stainless metal has the toughness of metal mixed with the corrosion resistance of nickel and the shininess of chromium. This tends to make it a helpful materials in programs exactly where you will need toughness mixed with magnificence and corrosion resistance..

Clever Alloys

These are alloys that can ‘remember’ their primary form. If they are deformed they can return to their primary form.

Condition memory glasses

Condition memory Stent to continue to keep a blocked blood vessel open

Metals, Alloys and Clever Alloys

Finding out Objectives:

To comprehend that the utilizes for particular metals relate to their unique qualities.

To comprehend that the qualities of metals can be improved by generating alloys.

To recall that some of the hottest alloys, called ‘Smart Alloys’ can change their qualities on demand from customers.