China Cheap price Nickel Alloy Hastelloy B UNS N10001 for Comoros Manufacturer

Our company puts emphasis on the management, the introduction of talented personnel, and the construction of staff building, trying hard to improve the quality and liability consciousness of staff members. Our company successfully attained IS9001 Certification and European CE Certification of China Cheap price Nickel Alloy Hastelloy B UNS N10001 for Comoros Manufacturer, Welcome to build the well and long standing business relationships with our company to create a glorious future together .customers' satisfaction is our eternal pursuit

HY HB Chemical compostion:

|

Alloy |

% |

Ni |

Mo |

Fe |

Cr |

Co |

C |

Mn |

V |

Si |

P |

S |

|

HY HB |

Min. |

Balance |

26 |

4 |

0.2 |

|||||||

|

Max. |

30 |

6 |

1 |

2.5 |

0.05 |

1 |

0.4 |

1 |

0.04 |

0.03 |

||

|

HY HB-2 |

Min. |

Balance |

26 |

2 |

||||||||

|

Max. |

30 |

7 |

1 |

1 |

0.02 |

1 |

0.1 |

0.04 |

0.03 |

HY HB Physical properties:

|

Density |

9.24g/cm3 |

|

Melting point |

1330-1380℃ |

HY HB Alloy minimum mechanical properties in the room temperature:

|

Alloy state |

Tensile strength |

Yield strength |

Elongation |

|

HY HB |

690 |

310 |

40 |

Characteristic:

1. Control of iron and chromium content to a minimum to prevent the generation of β-phase Ni4Mo.

2. Excellent corrosion resistance of restore environment.

3. An excellent resist to concentration sulfuric acid medium and large number of non-oxidizing acid corrosion.

4. A very good resistance of chloride reduction of stress corrosion cracking (SCC).

5. Good corrosion resistance of various organic acids.

Metallurgical structure

HY HB is the face-centered cubic lattice structure. By controlling the content of iron and chromium at the minimum to reduce the processing brittle, prevent Ni4Mo precipitation during 700-870 ℃.

Corrosion resistance

Ni-Mo alloy HY HB, the carbon and silicon content is extremely low, reducing the HAZ carbon and other impurities precipitation, so the weld has sufficient corrosion resistance. Alloy HY HBin the reduction of medium with very good corrosion resistance, such as a various temperature and concentration of hydrochloric acid. In the middle of the concentration of sulfuric acid solution (or contain a certain amount of chloride ions) also has very good corrosion resistance. At the same time can be used to acetic acid and phosphoric acid environment. Alloy material suitable only in the metallurgical structure and pure crystal structure in order to have the best corrosion resistance.

Applied field:

Alloy HY HB with a wide range of applications in the field of chemical, petrochemical, energy manufacturing and pollution control , particularly in the sulfuric acid, hydrochloric acid, phosphoric acid, acetic acid, and other industries.

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

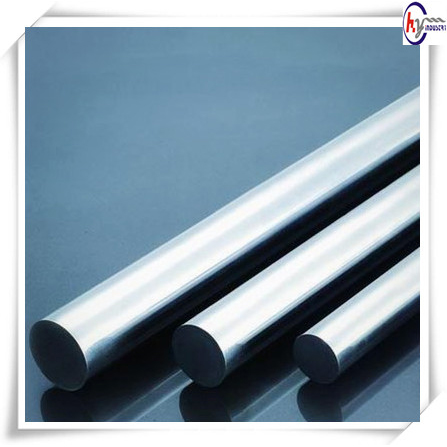

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

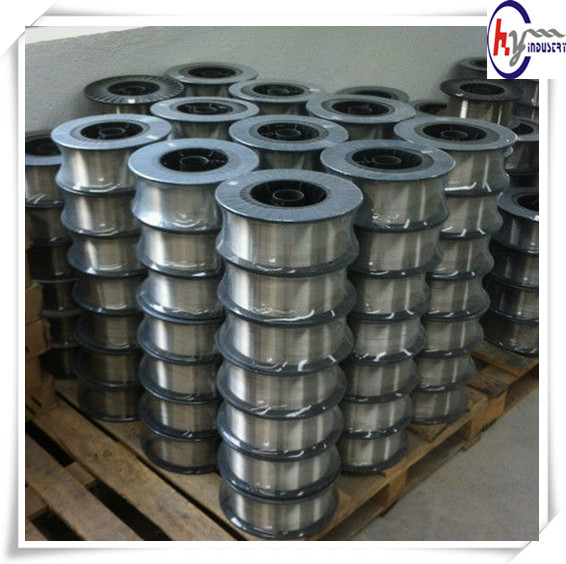

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

Inconel – Nickel Dependent Super Alloy – 600, 625, 718, X-750 Qualities and Programs August 2013 Inconel is a tremendous alloy and mixes effectively with Copper. Inconel arrives in a lot of varieties: Round Bar, Plate, Sheet, Pipe, Tube. Inconel is hard to machine for the reason that it perform hardens, Inconel 625 can be welded a bit.

Qingdao NPA Marketplace Co. Ltd is a foremost manufacturer specialized in centrifugal casting tube and static castings of warmth resistant alloys, which include ethylene cracking furnace tube, reformer furnace tube, CAL(constant annealing traces) &CGL(constant galvanizing traces) furnace roller and radiant tube, glass lehr roller and warmth/have on resistant castings. The annual potential is 9000 tons centrifugal casting tube and 3500 tons static castings (500 tons precision castings).

Internet site: www.npa-china.com