China Factory for Iron Alloy Precision Alloy 4J29 F15 Factory for Jamaica

Assume full responsibility to meet all demands of our clients; achieve continuous advancements by promoting the growth of our clients; become the final permanent cooperative partner of clients and maximize the interests of clients for China Factory for Iron Alloy Precision Alloy 4J29 F15 Factory for Jamaica, We are sincerely welcome good friends from numerous circles at dwelling and abroad come to cooperate!

HY J29 Material grades and equivalents

4J29/AISI/ASTM F15/JIS EMAS-1001/W.Nr 1.3912

HY J29 Chemical composition

|

Alloy |

% |

Ni |

Cr |

Fe |

Co |

Cu |

C |

Mn |

Si |

P |

S |

Mo |

|

HY J29 |

Min |

28.5 |

Rest |

16.8 |

||||||||

|

Max |

29.5 |

0.2 |

17.8 |

0.20 |

0.03 |

0.50 |

0.30 |

0.02 |

0.02 |

0.20 |

HY J29 Alloy Mechanical properties in the room temperature

|

Grade |

Average linear expansion factor(10-6℃) |

||||||

|

20℃~100℃ |

20℃~300℃ |

20℃~400℃ |

20℃~450℃ |

20℃~500℃ |

20℃~530℃ |

20℃~600℃ |

|

|

HY J29 |

- |

- |

4.6~5.2 |

5.1~5.5 |

- |

- |

- |

HY J29 Characteristic as below

HY J29 having similar coefficient of linear expansion with hard glass within a certain temperature range, applied to vacuum industry to match hard glass.

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

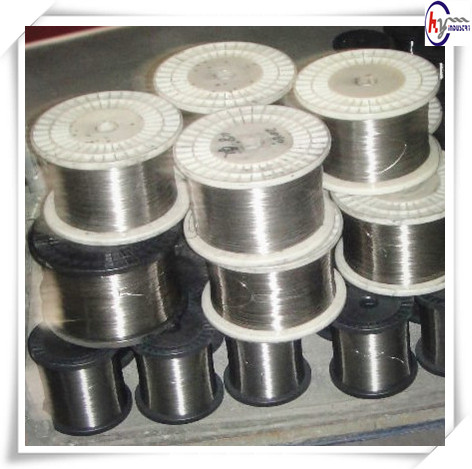

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

A nitinol wire/form memory alloy inchworm that walks across a table employing only warmth. The warmth is supplied by electrical existing heating up the skinny nitinol wire, causing it to return to its remembered form, a compressed coil in this scenario. A V-formed spring returns it to the commencing form.

Guidance RimstarOrg on Patreon https://www.patreon.com/user?u=680159

Subscribe for new films every single week http://www.youtube.com/user/rimstarorg?sub_affirmation=1

Go to the principal channel webpage below https://youtube.com/rimstarorg

See also:

How to Make Nitinol Wire Inchworm (Shape Memory Alloy)

https://www.youtube.com/look at?v=getfzfZJjHM

Nitinol Wire – How to Use it

https://www.youtube.com/look at?v=4Yi4epJ83EE

How a Rocket Performs/Earth to Area Eg SpaceX Falcon 9 and Dragon

https://www.youtube.com/look at?v=L0AMQ6kRNMA

My webpage about this nitinol wire inchworm:

http://rimstar.org/science_electronics_tasks/nitinol_wire_inchworm_form_memory_alloy_handmade.htm

Adhere to at the rear of-the-scenes on:

Twitter https://twitter.com/#!/RimStarz

Google+ https://additionally.google.com/116395125136223897621

Fb https://www.fb.com/rimstarorg

http://rimstar.org

The inspiration came from this one:

https://www.youtube.com/look at?v=DW4WaTmoZ3c

Essence – audio by audionautix.com

» Metal Tubes India is a GOVT. OF INDIA Acknowledged STAR EXPORT Dwelling & PED Accredited Maker

» Metal Tubes India is winner of All India Award for export excellence for 6 Consecutive Many years

» Metal Tubes India is an ISO 9001,ISO 14001,OHSAS 18001 Accredited company, our international CRISIL Ranking is SE 2B

» Metal Tubes India is European Force Machines Directive PED-97/23/EC qualified company

Ni 72., Cr fifteen.5, Fe 8. Mn 1. C .fifteen Cu .5 Si .5 S .015

Significant Efficiency Alloys stocks and produces this grade in the adhering to forms: Bar, wire, sheet, plate, coil, fasteners and forgings. Ask for quote on this grade.

Alloy 600 is a nickel-chromium alloy built for use from cryogenic to elevated temperatures in the selection of 2000 deg F(1093 deg C). The superior nickel material of the alloy allows it to retain substantial resistance less than lessening conditions and makes it resistant to corrosion by a range of natural and inorganic compounds. The nickel material gives it exceptional resistance to chloride-ion pressure-corrosion cracking and also offers exceptional resistance to alkaline options.

Inconel 600 Tube

ASME SB-163 ASME SB-516 ASME SB751 AMS 5580

UNS N06600 also offered in numerous forms like cap, elbow, erw pipes, fasteners, fittings, flange, plate, reducer, spherical bar, seamless pipes, sheet, tee and tube at industrial charge.

+ for extra info & specification about Inconel 600 remember to check out

http://www.steeltubesindia.internet/