China Professional Supplier Nickel Alloy Inconel 601 UNS N06601 Factory from Auckland

To constantly improve the management system by virtue of the rule of "sincerely, good faith and quality are the base of enterprise development", we widely absorb the essence of related products internationally, and constantly develop new products to meet the demands of customers for China Professional Supplier Nickel Alloy Inconel 601 UNS N06601 Factory from Auckland, We sincerely welcome overseas customers to consult for the long-term cooperation and the mutual development.

HY 601 Material grades and equivalents

Inconel 601 / GB NS313 / UNS N06601/W.Nr.2.4851 NiCr23Fe / AFNOR NC23FeA

HY 601 Chemaical composition:

|

Alloy |

% |

Ni |

Cr |

Fe |

C |

Mn |

Si |

Cu |

Al |

P |

S |

|

601 |

Min. |

58 |

21 |

1.0 |

|||||||

|

Max. |

63 |

25 |

balance |

0.1 |

1.5 |

0.5 |

1 |

1.7 |

0.02 |

0.015 |

HY 601 Physical properties

|

Density |

8.1g/cm3 |

|

Melting point |

1320-1370℃ |

HY 601 Alloy m inimum mechanical properties in the room temperature

|

Alloy state |

Tensile strength |

Yield strength |

Elongation |

Brinell hardness |

|

Annealing treatment |

650 |

300 |

30 |

- |

|

Solution treatment |

600 |

240 |

30 |

≤220 |

Characteristic as below:

1. Excellent inoxidability in the high temperature.

2. Good resistance to carbonizing.

3. Good inoxidabilitiy in sulfur atmosphere

4.Good mechanical property in both room temperature and high temperature.

5.Good resistance to stress corrosion cracking, 601 have high creep rupture strength since it limits the carbon content and grain size, so recommend to use for above 500℃ environment.

HY 601 Metallurgical structure:

601 is face-centered cubic lattice structure.

HY 601 Corrosion resistance

One of the mainly performance of 601 is inexorability in high temperature, even in very inclement conditions. If in the process of heating and cooling cycle, 601 can generate the dense layer of oxide film to get high spalling resistance. 601 have good carbonation resistance. With excellent inoxidability in the high temperature of sulfur atmosphere since it has high chromium and aluminum content.

HY 601 Application field:

1.The tray,basket and tool clamp in the heat treatment factory.

2.Steel shares at annealing and radiation control, high-speed gas burners, Industrial furnace silk screen.

3.Separate tank of ammonia reforming and catalytic support grid of nitric acid producing.

4.Exhaust system parts

5.Solid waste incinerator’s combustion chamber

6.Channel support and soot dealing parts.

7.Detoxification exhaust system components

8.Oxygen re-heater

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

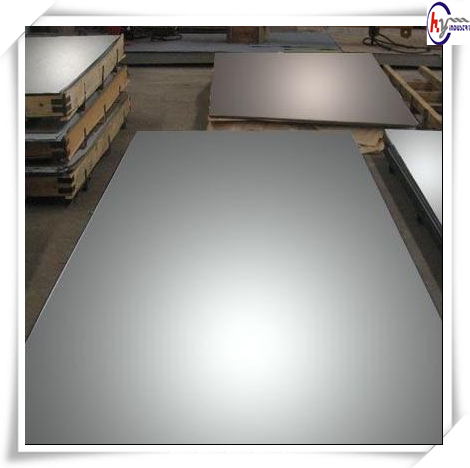

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

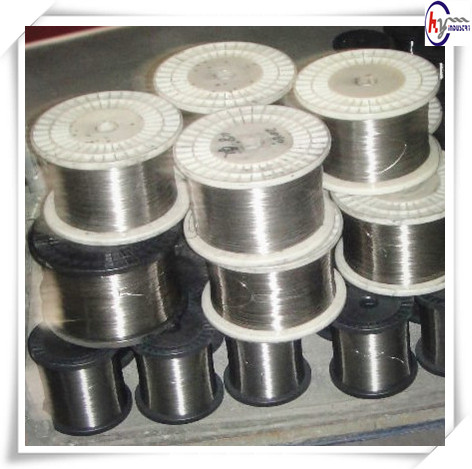

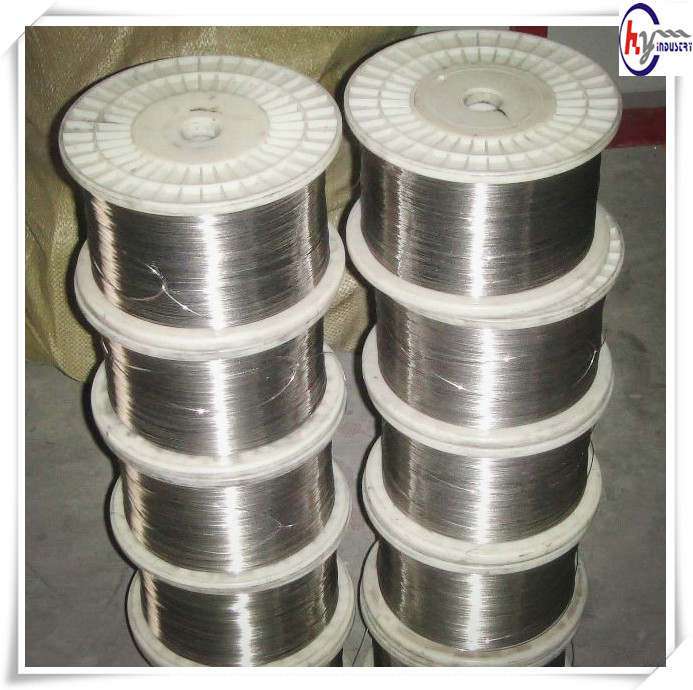

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

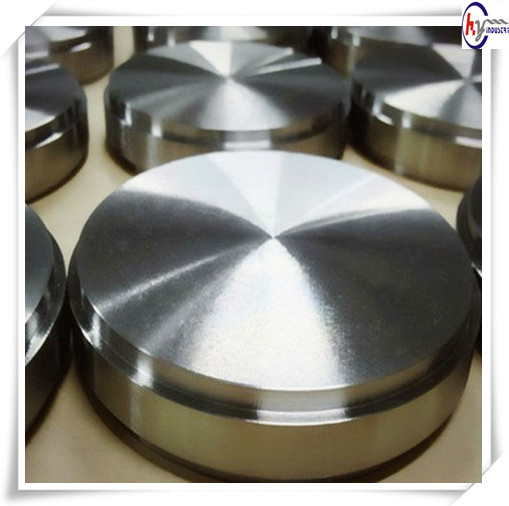

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

Melting down 1 gram bars of Silver, Copper, Nickel and Brass with hydrogen and oxygen. Brass is previously an alloy of copper and zinc, and did not soften down effortless as a I figured out from my Brass, Guide and Gunpowder video clip. I then blend the a few workable metals Silver, copper and nickel to generate…….Silvcopickel

SUBSCRIBE: http://comprehensive.sc/1bnslc9

Facebook: http://comprehensive.sc/1dT2aaM

RHNB Vs. Watermelon – http://comprehensive.sc/1bns60F

RHNB Vs. Jello – http://comprehensive.s/1bns0WF RHNB Vs. Elmers Glue – http://comprehensive.sc/1dT1TEM

RHNB Entire Playlist – http://comprehensive.sc/1dT1WjP -Want to ship an object / materials / substance to be RHNB’d or HHO’d? Send Here with a comprehensive credit of your donation! PO Box 21 96 Seymour St. Tonawanda NY 14150 Usa

Discovery and Science Channel’s How It truly is Designed Alloy Wheels episode.

All copyrights go to their respective homeowners.