China Wholesale for Iron Alloy Precision Alloy Invar 36 UNS K93600 Supply to Portugal

Reliable quality and good credit standing are our principles, which will help us at a top-ranking position. Adhering to the tenet of "quality first, customer supreme" for China Wholesale for Iron Alloy Precision Alloy Invar 36 UNS K93600 Supply to Portugal, If you are interested in our products, please feel free to send us your inquiry. We sincerely hope to establish win-win business relationships with you.

HY I36 Material grades and equivalents

GB 4J36/UNS K93600/AISI/ASTM Invar36/W.Nr.1.3912/Pernifer 36

Chemical composition

|

Alloy |

% |

Ni |

Cr |

Fe |

C |

Mn |

Si |

Co |

Mo |

P |

S |

|

HY I36 |

Min. |

35 |

Balance |

||||||||

|

Max. |

38 |

0.5 |

0.1 |

0.06 |

0.35 |

1.0 |

0.5 |

0.02 |

0.025 |

Physical properties

|

Density |

8.1 g/cm3 |

|

Melting point |

1430 °C |

Mechanical properties in the room temperature

|

Alloy state |

Tensile strength Rm N/mm2 |

Yield strength RP0.2N/mm2 |

Elongation A5 % |

Brinell hardness HB |

|

HY I36 |

490 |

240 |

42 |

≤200 |

Characteristic

HY I36 alloy is a special ultra-low coefficient of heat expansion of low-iron-nickel alloy. One of carbon and manganese element of control is very important. Cold deformation can reduce the coefficient of thermal expansion, in particular within the framework of the heat treatment temperature coefficient of thermal expansion will enable stabilization. Has the following characteristics:

1.Has very low coefficient of heat expansion between the temperature of -250°C and 200°C.

2.Good toughness and plastic

Metallurgical structure

HY I36 is the face centered cubic lattice structure

Corrosion resistance

HY I36 has corrosion resistance in the dry air of room temperature. In other harsh environments, such as the humid air, there may be corrosion (rust).

Applied field

HY I36 suit for need to apply ultra-low coefficient of heat expansion environment. Typical applications are as follows:

1.Liquefied gas production, storage and transport

2.The measurement and control instruments work temperature lower than 200°C, such as temperature regulating device

3.Metals and other materials use the screw connector bush

4.Bimetal and bimetallic temperature controller

5.Film framework

6.Shadow mask

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

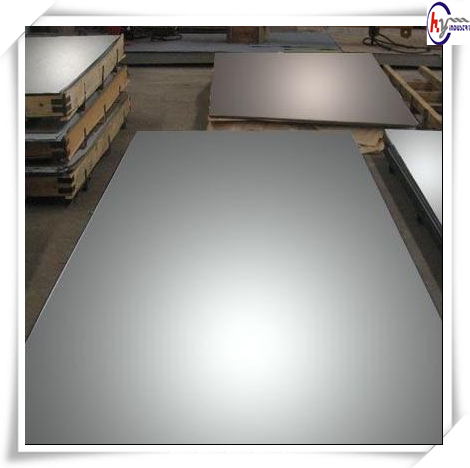

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

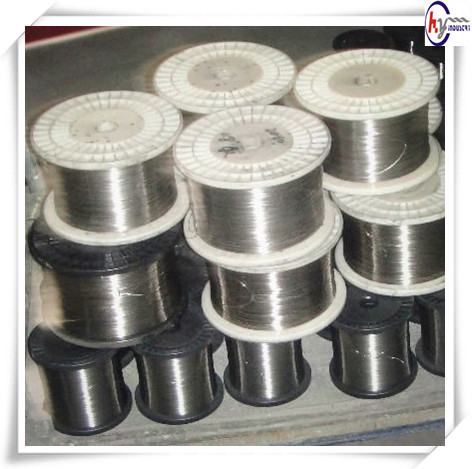

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

Inconel – Nickel Dependent Super Alloy – 600, 625, 718, X-750 Qualities and Programs August 2013 Inconel is a tremendous alloy and mixes effectively with Copper. Inconel arrives in a lot of varieties: Round Bar, Plate, Sheet, Pipe, Tube. Inconel is hard to machine for the reason that it perform hardens, Inconel 625 can be welded a bit.

Inconel 718, The Severe Metal Alloy. http://www.techsteel.web/alloy/nickel/inconel-718

Turbine Blades have revolutionized air vacation and electricity era.

Hundreds of slim precision blades spinning at a hundred,000 RPM have to have a materials that can stand up to excessive disorders.

Inconel 718 is a distinctive metal alloy that can stand up to excessive temperatures from -423° to 1300°F

This alloy is aged hardened, making it possible for it to be welded without having hardening for the duration of heating and cooling.

The improvement of Inconel began in the fifties for use in vital steam line plants. Originally used for armed service programs it was later on adopted by the professional sector.

Inconel 718‘s tolerance for excessive temperature make it specially perfectly suited for programs such as

turbine blades

nuclear electricity plants, and

aerospace programs. It was used in the space shuttles high force pump.

AMS 5589 | AMS 5596 | AMS 5597 | AMS 5663 | AMS 5664

For extra inconel 718 details take a look at techsteel.web

Tech Steel provides Specialty Alloys and Supplies.

Check out www.techsteel.web or phone 1-631-223-7638