Chinese wholesale Nickel Alloy Incoloy 800HT UNS N08811 Wholesale to Ukraine

Our development depends on the advanced equipment, excellent talents and continuously strengthened technology forces. Chinese wholesale Nickel Alloy Incoloy 800HT UNS N08811 Wholesale to Ukraine, Please send us your specifications and requirements, or feel free to contact us with any questions or inquiries that you may have.

HY 800HT

Material grades and equivalents

Incoloy 800HT/ UNS N08811/W.Nr.1.4959 X 8 NiCrAlTi 32-21/BS NA 15 (HT)

Incoloy 800H Chemical composition:

|

Alloy |

% |

Ni |

Cr |

Fe |

C |

Mn |

Si |

Cu |

S |

Al |

Ti |

|

800 |

Min. |

30 |

19 |

0.15 |

0.15 |

||||||

|

Max. |

35 |

23 |

balance |

0.1 |

1.5 |

1 |

0.75 |

0.015 |

0.6 |

0.6 |

|

|

800H |

Min. |

30 |

19 |

0.05 |

0.15 |

0.15 |

|||||

|

Max. |

35 |

23 |

balance |

0.1 |

1.5 |

1 |

0.75 |

0.015 |

0.6 |

0.6 |

|

|

800HT |

Min. |

30 |

19 |

0.06 |

0.15 |

0.15 |

|||||

|

Max. |

35 |

23 |

balance |

0.1 |

1.5 |

1 |

0.75 |

0.015 |

0.6 |

0.6 |

|

|

AI+Ti: 0.85-1.20 |

|||||||||||

Incoloy 800H Physical properties

|

Density |

8.0 g/cm³ |

|

Melting point |

1350-1400 ℃ |

Incoloy 800H Alloy minimum mechanical properties in the room temperature

|

Alloy |

Tensile strength |

Yield strength |

Elongation |

|

Rm N/mm² |

R P 0. 2N/mm² |

A 5 % |

|

|

800 |

500 |

210 |

35 |

|

800H |

450 |

180 |

35 |

800H Characteristic as below:

1.Excellent corrosion resistance in the water media of the extremely high temperature of 500℃.

2.Good stress corrosion resistance

3.Good machining

HY 800HTMetallurgical structure:

800H is face-centered cubic lattice structure. very low carbon centent and increased Ti:C rate

improve the stability of the structure, anti-allergy , and anti-intergranular corrosion. Low temperature annealing of 950℃ ensure the fine grain structure.

HY 800HTCorrosion resistance:

800H can not be corroded in many kinds of media. Its high nickel content made it have good stress corrosion resistance cracking property in the water corrosion condition.High Chromium content made it can better resist pitting and crevice corrosion cracking. This alloy can resist nitric acid and organic acid corrosion, but it is not so fine in the sulfuric acid and hydrochloric acid.

800H not only good corrosion resistance in both oxidation and non-oxidizing salt, maybe a little pitting in halide, but also very good corrosion resistance property in the mixture of water,smoke, steam,air and carbon dioxide.

HY 800HTApplication range and field:

1.Nitrate condenser—Corrosion resistance of nitrc acid

2.Steam heating pipes–Very good mechanical property

3.Heat up element tube–Very good mechanical property

For the application of up to 500℃ enviornment, alloy supply state change to annealing.

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

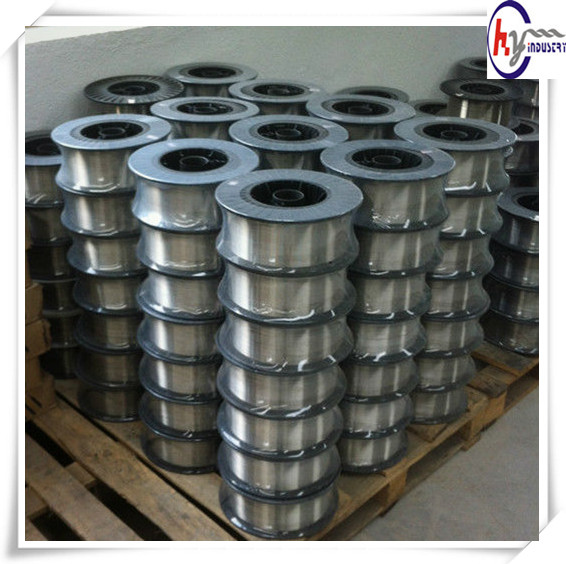

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

.025″ slash, 140sfm, VBMT 331 insert

» Metal Tubes India is a GOVT. OF INDIA Acknowledged STAR EXPORT Dwelling & PED Accredited Maker

» Metal Tubes India is winner of All India Award for export excellence for 6 Consecutive Many years

» Metal Tubes India is an ISO 9001,ISO 14001,OHSAS 18001 Accredited company, our international CRISIL Ranking is SE 2B

» Metal Tubes India is European Force Machines Directive PED-97/23/EC qualified company

Ni 72., Cr fifteen.5, Fe 8. Mn 1. C .fifteen Cu .5 Si .5 S .015

Significant Efficiency Alloys stocks and produces this grade in the adhering to forms: Bar, wire, sheet, plate, coil, fasteners and forgings. Ask for quote on this grade.

Alloy 600 is a nickel-chromium alloy built for use from cryogenic to elevated temperatures in the selection of 2000 deg F(1093 deg C). The superior nickel material of the alloy allows it to retain substantial resistance less than lessening conditions and makes it resistant to corrosion by a range of natural and inorganic compounds. The nickel material gives it exceptional resistance to chloride-ion pressure-corrosion cracking and also offers exceptional resistance to alkaline options.

Inconel 600 Tube

ASME SB-163 ASME SB-516 ASME SB751 AMS 5580

UNS N06600 also offered in numerous forms like cap, elbow, erw pipes, fasteners, fittings, flange, plate, reducer, spherical bar, seamless pipes, sheet, tee and tube at industrial charge.

+ for extra info & specification about Inconel 600 remember to check out

http://www.steeltubesindia.internet/