Factory Free sample Pure nickel Alloy Nickel 201 UNS N02201 for South Korea Manufacturers

Reliable quality and good credit standing are our principles, which will help us at a top-ranking position. Adhering to the tenet of "quality first, customer supreme" for Factory Free sample Pure nickel Alloy Nickel 201 UNS N02201 for South Korea Manufacturers, Welcome to build the well and long standing business relationships with our company to create a glorious future together .customers' satisfaction is our eternal pursuit

Material grades and equivalents

Nickel 201 /N02201/ W.Nr 2.4061

HY N201Chemical composition

|

Alloy |

% |

Ni |

Fe |

C |

Mn |

Si |

Cu |

S |

|

HY N201 |

Min. |

Balance | ||||||

|

Max. |

0.4 |

0.02 |

0.35 |

0.35 |

0.25 |

0.01 |

HY N201Pysical properties

|

Density |

8.89 g/cm³ |

|

Melting point |

1440℃ |

HY N201 Alloy minimum mechanical properties in the room temperature

|

Product Form |

Condition |

Tensile strength |

Yield strength |

Elongation A5 % |

Brinell hardness |

|

Rod & Bar |

Hot Finished |

60-85 |

15-45 |

35-55 |

45-80 |

|

Rod & Bar |

Cold Drawn/Annealed or Hot-Finished/Annealed |

55-75 |

15-30 |

40-55 |

45-70 |

|

Plate |

Hot-Rolled/Annealed |

55-80 |

15-40 |

40-60 |

45-75 |

|

Sheet |

Annealed |

55-75 |

15-30 |

40-55 |

70 max |

|

Tube & Pipe |

Seamless Annealed |

55-75 |

12-30 |

40-60 |

70 max |

HY N201Characteristic as below:

Highly resistant to various reducing chemicals

Excellent resistance to caustic alkalies

High electrical conductivity

Excellent corrosion resistance to distilled and natural waters

Resistance to neutral and alkaline salt solutions

Excellent resistance to dry fluorine

Widely used to handle caustic soda

Good thermal, electrical and magnetostrictive properties

Offers some resistance to hydrochloric and sulfuric acids at modest temperatures and concentrations

HY N201 Application field :

Food processing equipment

Marine and offshore engineering

Salt production

Caustic handling equipment

Manufacture and handling of sodium hydroxide, particularly at temperatures above 300° F

Reactors and vessels in which fluorine is generated and reacted with hydrocarbons

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

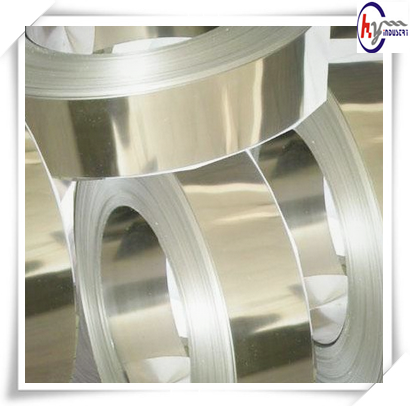

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

Discovery and Science Channel’s How It truly is Designed Alloy Wheels episode.

All copyrights go to their respective homeowners.

The progress of improved metallic resources is a crucial action at the leading edge of science and know-how. Metals offer unrivalled mixtures of houses and reliability at a cost which is economical. They are adaptable mainly because subtle improvements in their microstructure can cause dramatic variations in their houses. For illustration, it is feasible to purchase business steel with a energy as lower as 50 MPa or as large as 5500 MPa. They can be built with a microstructure which is finer than that of carbon nanotubes. An understanding of the progress of microstructure in metals, rooted in thermodynamics, crystallography and kinetic phenomena is crucial for the resources scientist. The bulk of the 1.4 billion tonnes of metals made annually are the outcome of developments within just the last 10 a long time

http://www.msm.cam.ac.british isles/phase-trans/2002/creep.1.html