Factory Outlets Heat Resistant Wire 0Cr25Al5 Fe-Cr-Al Alloy wire to Qatar Factories

"Quality first, Honesty as base, Sincere service and mutual profit" is our idea, in order to develop continuously and pursue the excellence for Factory Outlets Heat Resistant Wire 0Cr25Al5 Fe-Cr-Al Alloy wire to Qatar Factories, If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

HY 0255 Material grades and equivalents

0Cr25Al5 / 0Al5Cr25

HY 0255 Grade property performance

|

Grade property performance |

HY 0255 |

|

|

% Main Chemical Composition |

Cr |

23~26 |

|

Al |

4.5~5.5 |

|

|

Fe |

Balance |

|

|

Mn |

≤0.7 |

|

|

Nb |

— |

|

|

℃ Max contimnous service Temp. of element |

1250 |

|

|

Resistivity mm2/m |

1.42±0.07 |

|

|

10-5/℃ Temp coeff of resistance |

5 |

|

|

g/cm3 Density 密度 |

7.1 |

|

|

Melting point≈ ℃ (approxi) |

1500 |

|

|

Tensile strength N/mm2 |

637~784 |

|

|

% Elongation |

>12 |

|

|

% Reducation of Area |

65~75 |

|

|

Hardness(HB) |

200~260 |

|

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

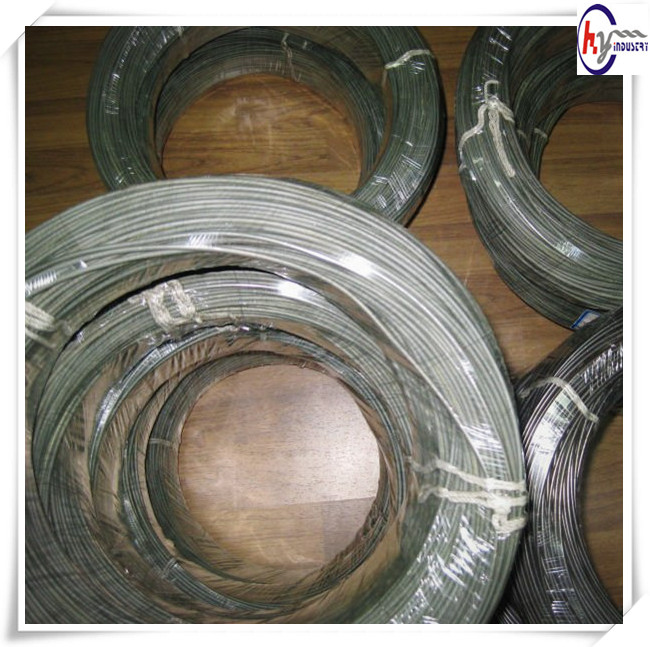

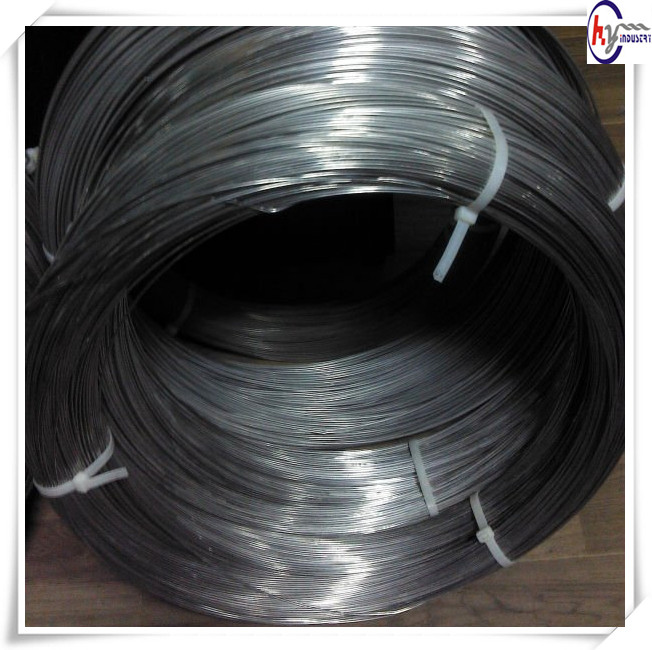

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

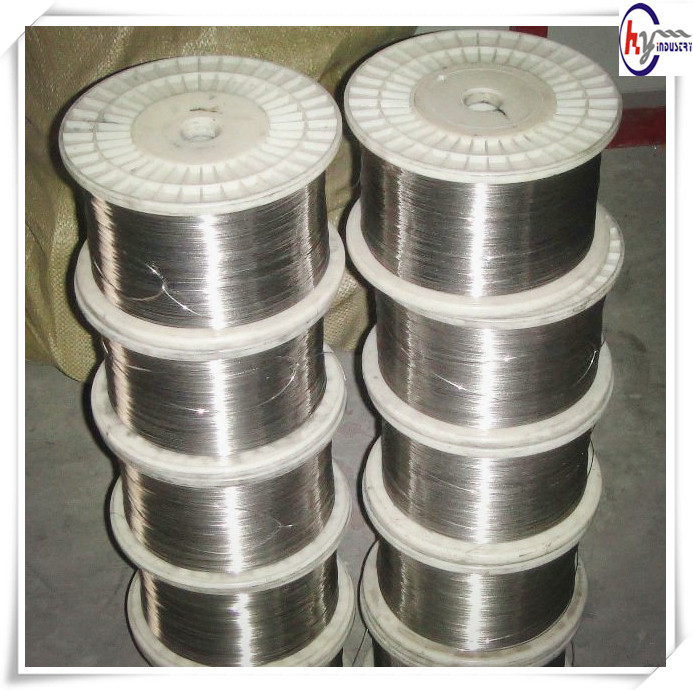

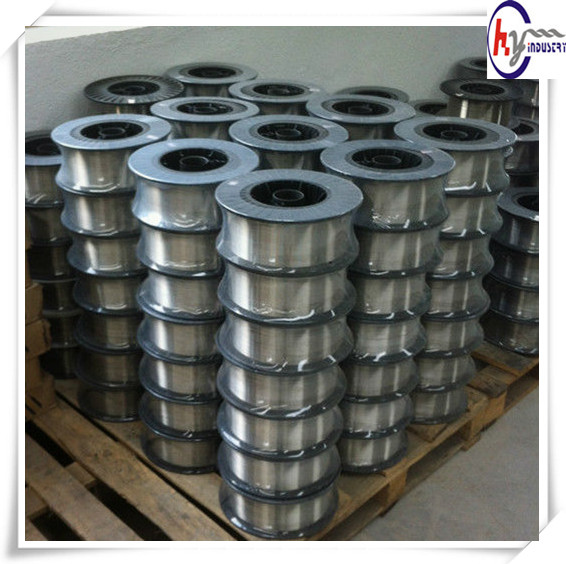

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

Welding Inconel 718

http://www.weldingtipsandtricks.com/metals-and-how-to-weld-nickel.html

How to weld nickel alloys like hastelloy, inconel, etc. Nickel alloys have a low thermal conductivity and so limiting heat input and using lower amperage than would be used for stainless is one key to making good nickel alloy welds.