Factory source manufacturing Titanium alloy 6Al-2Sn-4Zr-2Mo UNS R54620 Supply to UK

we can offer high quality products, competitive price and best customer service. Our destination is "You come here with difficulty and we give you a smile to take away" for Factory source manufacturing Titanium alloy 6Al-2Sn-4Zr-2Mo UNS R54620 Supply to UK, We warmly welcome customers from all over the world for any kind of cooperation with us to build a mutual benefit future. We are devoting ourselves wholeheartedly to offer customers the best service.

HY Titanium 6-2-4-2 Material grades and equivalents

6Al-2Sn-4Zr-2Mo, 6-2-4-2 Titanium, 6-2-4-2, UNS R54620

Introduction

A near-alpha alloy, primarily used for high strength and toughness, with good creep resistance up to 1000°F. Forging and machining characteristics similar to those of Ti 6Al-4V. Applications include compressor components, hot airframe skin, and engine afterburner structures. The weld ability of Ti 6-2-4-2 is fair, using AMS 4952 weld wire. Several different treatments are available.

Chemistry Composition

|

|

Al |

Sn |

Zr |

Mo |

C |

N |

H |

O |

Si |

Fe |

Y |

Others, |

Others, |

Ti |

|

MIN |

5.5 |

1.8 |

3.6 |

1.8 |

- |

- |

- |

- |

0.06 |

- |

- |

- |

- |

- |

|

MAX |

6.5 |

2.2 |

4.4 |

2.2 |

0.05 |

0.05 |

0.015 |

0.12 |

0.1 |

0.25 |

0.005 |

0.1 |

0.3 |

Balance |

Features

- Machinability similar to austenitic stainless steels

- Easily welded if proper precautions are taken to prevent oxygen, nitrogen and hydrogen contaminations

- Long term stability for temperatures up to 800°F

Applications

- Compressor discs, blades

- Airframe structure, skin

- Engine afterburner components

- Hush kits

Physical Properties

Density: 0.160 lb/in3

Beta Transus: 1825±25°F

Thermal Conductivity: 4.00 Btu • hr/ft2 • hr°F

Coefficient of Thermal Expansion: 32-212°F 4.3 x10-6 in/in°F

Modulus of Elasticity: 16.5×106 psi

Mechanical Properties

Minimum Tensile Properties, AMS 4919, Duplex Annealed

|

Thickness, in |

0.025 ≤ 0.062 |

> 0.062 ≤ 1.000 |

> 1.000 ≤ 3.000 |

|

Tensile Strength, ksi |

135,000 |

135,000 |

135,000 |

|

0.2% offset Yield Strength, ksi |

125,000 |

125,000 |

125,000 |

|

Elongation, % |

8 |

10 |

10 |

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

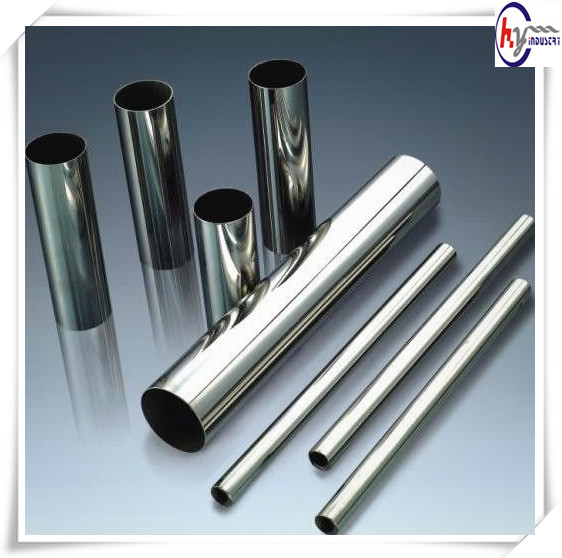

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

A nitinol wire/form memory alloy inchworm that walks across a table employing only warmth. The warmth is supplied by electrical existing heating up the skinny nitinol wire, causing it to return to its remembered form, a compressed coil in this scenario. A V-formed spring returns it to the commencing form.

Guidance RimstarOrg on Patreon https://www.patreon.com/user?u=680159

Subscribe for new films every single week http://www.youtube.com/user/rimstarorg?sub_affirmation=1

Go to the principal channel webpage below https://youtube.com/rimstarorg

See also:

How to Make Nitinol Wire Inchworm (Shape Memory Alloy)

https://www.youtube.com/look at?v=getfzfZJjHM

Nitinol Wire – How to Use it

https://www.youtube.com/look at?v=4Yi4epJ83EE

How a Rocket Performs/Earth to Area Eg SpaceX Falcon 9 and Dragon

https://www.youtube.com/look at?v=L0AMQ6kRNMA

My webpage about this nitinol wire inchworm:

http://rimstar.org/science_electronics_tasks/nitinol_wire_inchworm_form_memory_alloy_handmade.htm

Adhere to at the rear of-the-scenes on:

Twitter https://twitter.com/#!/RimStarz

Google+ https://additionally.google.com/116395125136223897621

Fb https://www.fb.com/rimstarorg

http://rimstar.org

The inspiration came from this one:

https://www.youtube.com/look at?v=DW4WaTmoZ3c

Essence – audio by audionautix.com