Factory wholesale Titanium alloy 10V-2Fe-3Al UNS R56410 Wholesale to Amsterdam

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Factory wholesale Titanium alloy 10V-2Fe-3Al UNS R56410 Wholesale to Amsterdam, Adhering to the business principle of mutual benefits, we have won good reputation among our customers because of our perfect services, quality products and competitive prices. We warmly welcome customers from home and abroad to cooperate with us for common success.

HY Titanium 10-2-3 Material grades and equivalents

10-2-3 Titanium, UNS R56410

Introduction

HY Titanium 10-2-3 is a near beta alloy developed as a high strength forging alloy. This grade provides the best combination of strength and toughness of the commercially available titanium alloys. Its strength permits about a 27% weight savings when compared to Ti-6Al-4V. At the 180 ksi tensile strength level, the K1cvalue is 40 ksi-in ½ minimum. Solution treated and aged material possesses excellent resistance to stress corrosion cracking, typically K1scc being greater than 0.8 K1c. Solution treated material should not be subject to long term exposure in the 500-800°F range. This could result in high strength but low ductility.

High strength condition: Solution treat 60-100°F below the beta transus (typically 1460-1480°F), not less than 30 minutes, water quench. Age 900-975°F not less than 8 hours, air cool. For lower strength, overage in the 950-1150°F range. This alloy is deep hardenable, capable of high strengths in sections up to approximately 4″ thick.

This grade is usually supplied as billet or bar, finish rolled or forged in the alpha-beta field. For the high strength condition, the forging is usually given a pre-form forge above the beta transus, followed by 15-25% reduction below the beta transus.

Chemistry Composition

|

|

V |

Al |

Fe |

C |

N |

O |

H |

Y |

Others, |

Others, |

Ti |

|

MIN |

9.0 |

2.6 |

1.6 |

- |

- |

- |

- |

- |

- |

- |

- |

|

MAX |

11.0 |

3.4 |

2.22 |

0.05 |

0.05 |

0.13 |

0.015 |

0.005 |

0.10 |

0.30 |

Balance |

Features

- High strength and toughness

- Weight savings when compared to Ti-6Al-4V

- Excellent resistance to stress corrosion cracking

Applications

- Hand and die forgings

- Aircraft landing gear

- Golf club driver faces

Physical Properties

Density: 0.168 lb/inch³

Nominal Beta Transus: 1470°F

Poisson’s ratio: 0.32

Thermal Expansion: 75-800°F, 5.4×10-6 in/in°F

Tensile Modulus: 15.9×106 psi

Modulus: 16.2×106 psi

* 70°F to indicated temperature.

Mechanical Properties

Minimum Mechanical Properties AMS 4984, solution treated and aged

|

Ultimate Tensile Strength, ksi |

173 |

|

Ultimate Tensile Strength, ksi |

160 |

|

0.2% Yield Strength, ksi |

4 |

|

Reduction of Area, % |

Report |

|

fracture toughness, k1C |

40 ksi |

AMS 4987, single solution heat treat & overage

|

Ultimate Tensile Strength, ksi |

140 |

|

0.2% Yield Strength, ksi |

130 |

|

Elongation, % |

8 |

|

Reduction of Area, % |

20 |

|

fracture toughness, k1C |

80 ksi |

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

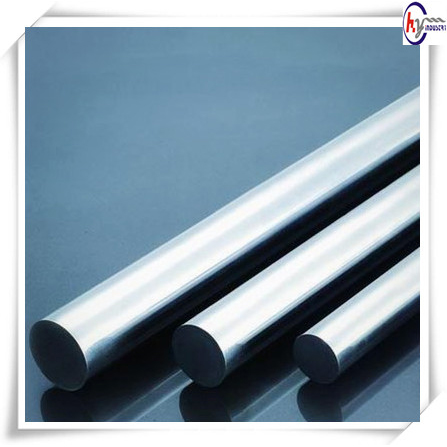

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

NEW 2016 Chrysler three hundred S Alloy Edition Sedan with a Gloss Black Paint finish. AWD that seats five with a three.two L V-six engine and an eight velocity computerized transmission. 19″ alluminum alloy rims with Michelin Primacy MXM4 tires. This sedan will come thoroughly loaded with keyless entry, distant get started, power locks, home windows, mirrors, Beats by Dre audio system, AM/FM, Sirius Sat radio, Lcd display screen in the entrance with back up digicam, leather all over with heated entrance and rear seats and so significantly a lot more. Come check out it out at Ponoka Chrysler and see what else it has to present, we are located on the south conclusion of Ponoka just off of HWY 2A.

Stock# 16C37644

Sarah Johnson,

Ponoka Chrysler

6510 39th Ave Ponoka, AB T4J 1J8

Toll Cost-free: 1(800) 265-6851

Cellphone: (403) 783-5383

Fax: (403) 783-8140

E-mail: sjohnson@ponokachrysler.com

Like us on Fb- https://www.facebook.com/PonokaChrysler/

Abide by us on Instargram- https://www.instagram.com/ponokadodge/

Abide by us on Twitter- https://twitter.com/PonokaDodgeRam

Abide by us on Pintrest- https://www.pinterest.com/ponokachrysler/

Visit my site for additional Recommendations, Films, Do it yourself assignments and additional:

http://www.mjlorton.com/

—————————–Click “Display additional”—————————————

A information on making use of the correct applications to crimp connectors, strip wire and implement warmth shrink.

You should guidance my information generation by making use of my Amazon Retail store:

http://astore.amazon.com/m0711-twenty

Purchase these applications and connectors below: http://astore.amazon.com/m0711-twenty?node=ten&site=one

——————— Click “Display additional” ——————————-

My site and forum:- http://www.mjlorton.com

Donations and contributions:- http://www.mjlorton.com

My techie channel MJLorton – Solar Power and Digital Measurement Products – http://www.youtube.com/MJLorton

My Techie Amazon Retail store: http://astore.amazon.com/m0711-twenty

My other channel VBlogMag – For nearly any matter beneath the sun! – http://www.youtube.com/VBlogMag

My VBlogMag Amazon Retail store: http://astore.amazon.com/vblogmag-twenty

———————————————————————–

=================================================

Online video sponsor, Pass Ltd – their internet websites:

http://www.tester.co.united kingdom/?cmid=QmhzQjcxYjVlc1E9&afid=bFcwbzliNzVDc289&ats=K2EyUjZNTDh3UTA9 – Examination Products and Examination-meter suppliers and

http://www.calibrate.co.united kingdom/?cmid=QmhzQjcxYjVlc1E9&afid=bFcwbzliNzVDc289&ats=S3Yxd2tOMjVISzA9 – Calibration and support of exam tools

=================================================

Additional dialogue and link to NASA information below:

http://mjlorton.com/forum/index.php?matter=244.

In this online video:

* Deciding upon the correct wire gauge (AWG – American Wire Gauge) for the crimp connector.

* Employing the correct applications to strip the insulation from the wire.

* The correct way to insert the wire into the crimp connector

* Employing the correct crimp applications to crimp the connector

* How to implement warmth shrink accurately to the wire and crimp connector.