Fixed Competitive Price Nickel Alloy Inconel 617 UNS N06617 Factory in Sri Lanka

owing to good service, a variety of high quality products, competitive prices and efficient delivery, we enjoy a good reputation among our customers. We are an energetic company with wide market for Fixed Competitive Price Nickel Alloy Inconel 617 UNS N06617 Factory in Sri Lanka, If you have any comments about our company or products, please feel free to contact us, your coming mail will be highly appreciated.

HY617 Material grades and equivalents

Inconel 617/ UNS N07617 / SEW VDIUV W.Nr.2.4663 NiCr23Co12Mo / AFNOR NC22KDA

HY 617 is a solid-solution, strengthened, nickel-chromium-cobalt- molybdenum alloy with an exceptional combination of high-temperature strength and oxidation resistance. The alloy also has excellent resistance to a wide range of corrosive environments, and it is readily formed and welded by conventional techniques.

The combination of high strength and oxidation resistance at temperatures over 1800°F (980°C) makes HY617 an attractive material for such components as ducting, combustion cans, and transition liners in both aircraft and land-based gas turbines.

HY 617 Chemical composition:

|

Alloy |

% |

Ni |

Cr |

Fe |

C |

Mn |

Si |

Mo |

Co |

Al |

Ti |

P |

S |

|

617 |

Min |

20 |

0.05 |

8 |

10.0 |

0.6 |

0.2 |

||||||

|

Max |

Rest |

23 |

2.0 |

0.1 |

0.7 |

0.7 |

10.0 |

13.0 |

1.5 |

0.6 |

0.012 |

0.008 |

HY 617 Physical properties:

|

Density |

8.4 g/cm3 |

|

Melting Point |

1330-1380℃ |

Corrosion Resistance

elevated temperatures, those elements cause the formation of a thin, subsurface zone of oxide particles.

The zone forms rapidly upon exposure to high temperatures until it reaches a thickness of 0.001 to 0.002

in. (0.025 to 0.05 mm). The oxide zone provides the proper diffusion conditions for the formation of a

protective chromium oxide layer on the surface of the metal. It also helps to prevent spalling of the

protective layer.

HY 617 has excellent resistance to carburization. Table 9 compares alloy 617 and some other

carburization-resistant alloys in a gaseous carburizing environment at 2000°F (1095°C). The weight-gain

measurements indicate the amount of carbon absorbed during the test period. The composition of INCONEL alloy 617 includes substantial amounts of nickel, chromium, and aluminum for

a high degree of resistance to oxidation and carburization at high temperatures. Those elements, along

with the molybdenum content, also enable the alloy to withstand many wet corrosive environments.

Heat Treatment

HY 617 is normally used in the solutionannealed condition. That condition provides a coarse grain

structure for the best creep-rupture strength. It also provides the best bend ductility at room temperature. Solution

annealing is performed at a temperature of 2150°F (1175°C)for a time commensurate with section size.

Cooling should be by water quenching or rapid air cooling.

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

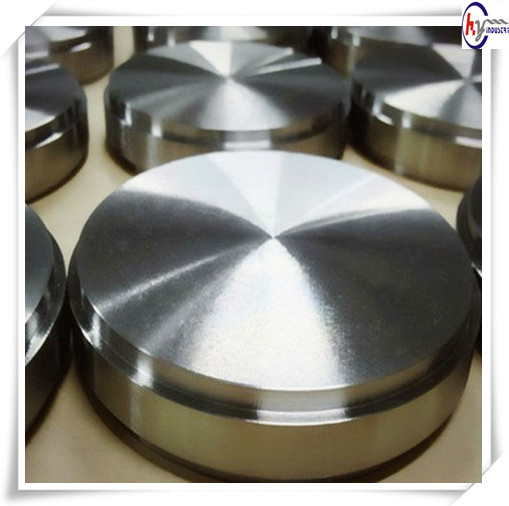

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

This is our 4000 watt Co2 laser slicing process. We can cut Stainless Steel and alloys to .five hundred”, Steel and metal alloys to .750″ and aluminum to .375″. Equally our devices have big bed dimensions, just one is sixty” x 120″ and the 3000 watt is seventy eight” x 157″. Equally devices have automatic loading and shuttle tables for prototyping to manufacturing.

Inconel 718, The Severe Metal Alloy. http://www.techsteel.web/alloy/nickel/inconel-718

Turbine Blades have revolutionized air vacation and electricity era.

Hundreds of slim precision blades spinning at a hundred,000 RPM have to have a materials that can stand up to excessive disorders.

Inconel 718 is a distinctive metal alloy that can stand up to excessive temperatures from -423° to 1300°F

This alloy is aged hardened, making it possible for it to be welded without having hardening for the duration of heating and cooling.

The improvement of Inconel began in the fifties for use in vital steam line plants. Originally used for armed service programs it was later on adopted by the professional sector.

Inconel 718‘s tolerance for excessive temperature make it specially perfectly suited for programs such as

turbine blades

nuclear electricity plants, and

aerospace programs. It was used in the space shuttles high force pump.

AMS 5589 | AMS 5596 | AMS 5597 | AMS 5663 | AMS 5664

For extra inconel 718 details take a look at techsteel.web

Tech Steel provides Specialty Alloys and Supplies.

Check out www.techsteel.web or phone 1-631-223-7638