Free sample for Nickel Alloy Inconel 686 UNS N06686 for Southampton Factory

abide by the contract", conforms to the market requirement, joins in the market competition by its high quality as well as provides more comprehensive and excellent service for clients to let them become big winner. The pursue of the company, is the clients' satisfaction for Free sample for Nickel Alloy Inconel 686 UNS N06686 for Southampton Factory, welcomes all overseas friends and merchants to establish collaboration with us. We will provide you with honest, high quality and efficient service to meet your requirements.

HY 686 Material grades and equivalents

Inconel 686 / UNS N06686 / Werkstoff Nr.2.4606

HY 686 Chemical composition:

|

Type |

% Main Chemical Composition % |

||||||||||

|

Mo |

Cr |

Fe |

W |

C |

Si |

Mn |

P |

S |

Ti |

Ni |

|

|

HY 686 |

15.0~17.0 |

19.0~23.0 |

≤5.0 |

3.0~4.4 |

≤0.01 |

≤0.08 |

≤0.75 |

≤0.04 |

≤0.02 |

0.02-0.25 |

Rest |

HY 686 Physical properties:

| Density | Melting range | Hardness |

| 8.73 | 1338~1380 | HRC36 |

HY 686 Alloy minimum mechanical properties in the room temperature

|

Condition |

Tensile Strength |

Yield strength |

Elongation |

|

Rm N/mm² |

R P 0. 2N/mm² |

A 5 % |

|

|

Solution |

690 |

380 |

45 |

|

Cold Drawing/Hot Rolled |

1115 |

1020 |

23.1 |

HY 686 Characteristic as below

HY 686 is solid solution strengthening and corrosion resistance nickel based alloy of NI-Cr-Mo, which has good corrosion resistance in severe corrosive environment. They mainly apply to heat exchanger, reaction container and delivery pipe in the area of chemical processing, processing, pollution control, papermaking, industry and garbage treatment etc.

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

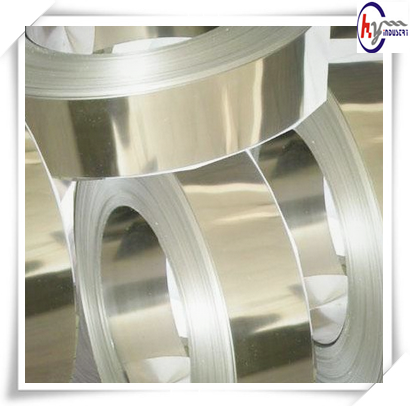

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

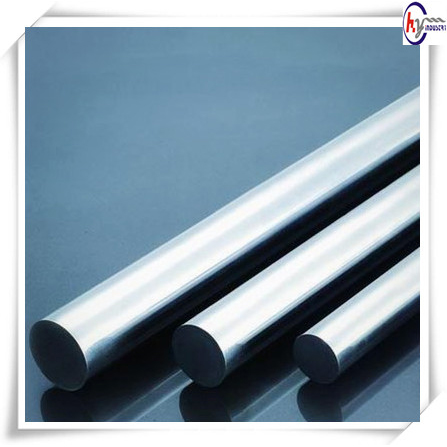

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

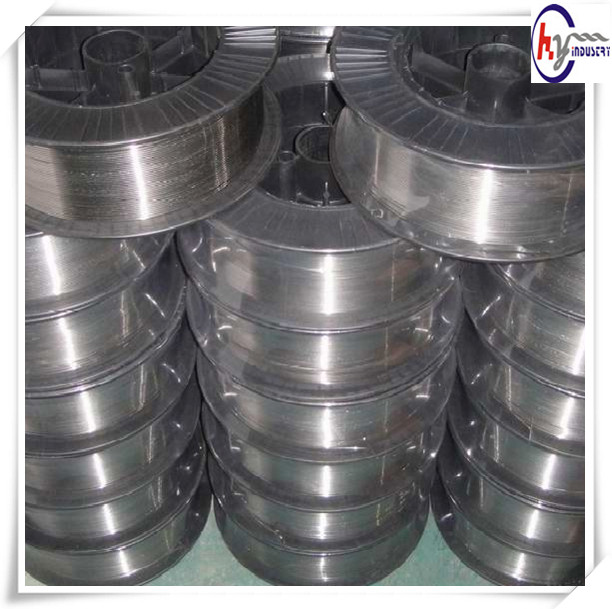

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

This is our 4000 watt Co2 laser slicing process. We can cut Stainless Steel and alloys to .five hundred”, Steel and metal alloys to .750″ and aluminum to .375″. Equally our devices have big bed dimensions, just one is sixty” x 120″ and the 3000 watt is seventy eight” x 157″. Equally devices have automatic loading and shuttle tables for prototyping to manufacturing.

Welding Inconel 718