Good User Reputation for Titanium alloy 6Al-4V ELI UNS R56401 for New Zealand Factory

Our company promises all users of the first-class products and the most satisfying post-sale service. We warmly welcome our regular and new customers to join us for Good User Reputation for Titanium alloy 6Al-4V ELI UNS R56401 for New Zealand Factory, Adhering to the business principle of mutual benefits, we have won good reputation among our customers because of our perfect services, quality products and competitive prices. We warmly welcome customers from home and abroad to cooperate with us for common success.

HY Titanium 6-4 ELI Material grades and equivalents

6-4 ELI Titanium, 6-4 ELI, UNS R56401

Introduction

Low interstitial version of HY Titanium 6-4 ELI, for maximum toughness. Preferred for marine and cryogenic applications. This grade is normally used in the annealed condition. HY Titanium 6-4 ELI is the preferred choice for the medical implant field.

Stress relief 900-1200°F 1 to 4 hours, air cool. Duplex anneal, bar and forgings: Solution anneal 50-100°F below the beta transus, hold 1 hour minimum, air cool. Then reheat within the range 1300-1400°F, hold 1 hour minimum, air cool. Stress – relief annealing is performed after welding.

Chemistry Composition

|

|

Al |

V |

Fe |

O |

C |

N |

H |

Y |

Others, |

Others, |

Ti |

|

MIN |

5.5 |

3.5 |

– |

– |

– |

– |

– |

– |

– |

– |

– |

|

MAX |

6.5 |

4.5 |

0.25 |

0.13 |

0.08 |

0.03 |

0.0125 |

0.005 |

0.1 |

0.4 |

Balance |

Features

- Resistant to bodily fluids

- Resistant to a variety of corrosive environments

- Freedom from chloride stress corrosion cracking

- Good strength and toughness over a wide temperature range

- High resistance to erosion corrosion and corrosion fatigue

- Useful resistance to dry chlorine, fluorine, hydrogen chloride and hydrogen fluoride gases

Applications

- Medical and dental implants

- Cryogenics

- Aerospace

- Chemical processing

Physical Properties

Density: 0.160 lb/in3

Melting Range: 2370 – 2460°F

Beta Transus: 91790+25°F

Minimum Tensile Properties, AMS 4919, Duplex Annealed

|

Temperature, °F |

68-212 |

68-600 |

68-1000 |

68-1200 |

68-1500 |

|

Coefficient* of Thermal Expansion, in/in°F x 10-6 |

9.18 |

9.54 |

10.08 |

10.44 |

10.8 |

Mechanical Properties

Typical hardness Rockwell: C 30-34 Specific minimums, AMS 4931, bar and forging

Representative Tensile Properties, Sheet

|

Diameter, in |

< 3.0 |

< 3.0 < 4.0 |

< 4.0) < 6.0 |

|

Tensile Strength, ksi |

125 |

123 |

120 |

|

0.2 % Yield Strength, ksi |

115 |

110 |

110 |

|

Elongation, % *L (**ST) |

10 (8) |

10 (8) |

8 (8) |

|

Reduction of Area, % *L (**ST) |

25 (–) |

20 (15) |

15 (15) |

* Longitudinal ** Short Transverse

Typical Elevated temperature Properties

|

Temperature, °F |

93 (200) |

149 (300) |

204 (400) |

260 (500) |

|

Ultimate Tensile Strength, ksi |

843.3 (121) |

772.2 (112) |

723.9 (105) |

657.7 (98) |

|

0.2 % Yield Strength, ksi |

710.2 (103) |

641.2 (93) |

586.1 (85) |

531.0 (77) |

|

Elongation, % |

13 |

15 |

16 |

16 |

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

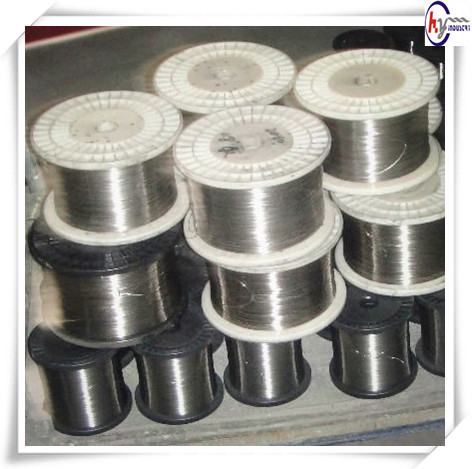

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

I am earning my own wedding day band from Inconel X-750 just to be diverse. The material is a agony to do the job with thanks to the superior nickel/chromium articles. The lathe is a LeBlond “dual generate” with an Aloris-copy device article. I built an adapter for the one.25″ boring bar socket to sleeve it down to a 5/8″ side-lock drill shank. I utilised an indicator to sweep the device holder, inserting it instantly on center. The drill is a Seco CrownLoc As well as with .625″ tip, running at around 80sfm, hand feed with plenty of stress, and drenched in reducing oil (not demonstrated in pic). Chips had been astonishingly limited of course, I had to withdrawal the device numerous moments to eliminate chips, due to the fact they weren’t becoming flushed by coolant.

Qingdao NPA Marketplace Co. Ltd is a foremost manufacturer specialized in centrifugal casting tube and static castings of warmth resistant alloys, which include ethylene cracking furnace tube, reformer furnace tube, CAL(constant annealing traces) &CGL(constant galvanizing traces) furnace roller and radiant tube, glass lehr roller and warmth/have on resistant castings. The annual potential is 9000 tons centrifugal casting tube and 3500 tons static castings (500 tons precision castings).

Internet site: www.npa-china.com