High Definition For Titanium alloy 6Al-4V STA UNS R56400 for Latvia Factories

we can offer high quality products, competitive price and best customer service. Our destination is "You come here with difficulty and we give you a smile to take away" for High Definition For Titanium alloy 6Al-4V STA UNS R56400 for Latvia Factories, sincerely look forward to serving you in the near future. You are sincerely welcome to visit our company to talk business face to face with each other and establish long-term co-operation with us!

HY Titanium 6-4 STA Material grades and equivalents

6-4 STA Titanium, 6-4 STA, Ti 6-4 STA, UNS R56400

Introduction

HY Titanium 6-4 STA (Solution Treated and Aged) is a modified version of Ti 6Al-4V. It is heat treated for high strength in sections under 4″ thick. Ti-6Al-4V has excellent hardenability in sections up to 1″ thick with strengths as high as 165 ksi.

For maximum strength: solution-treated and aged (STA) condition is: For sheet, 1675-1725°F 5 to 25 minutes, water quench. Age 975°F 4 to 6 hours, air cool. For bars and forgings, 1675-1725°F 1 hour, water quench. Age 975-1025°F 4 to 8 hours, air cool.

HY Titanium 6-4 STA is resistant to general corrosion but may be quickly attacked by environments that cause breakdown of the protective oxide. These include hydrofluoric (HF), hydrochloric (HCl), sulfuric and phosphoric acids. Inhibitors may help for the last three but not for HF. Ti 6Al-4V STA resists attack by pure hydrocarbons, and most chlorinated and fluorinated hydrocarbons (provided water has not caused formation of small amounts of HCl and HF).

Chemistry Composition

|

|

Al |

V |

C |

N |

O |

H |

Fe |

Y |

Others, |

Others, |

Ti |

|

MIN |

5.5 |

3.5 |

– |

– |

– |

– |

– |

– |

– |

– |

– |

|

MAX |

6.75 |

4.5 |

0.08 |

0.05 |

0.2 |

0.0125 |

0.3 |

0.005 |

0.1 |

0.4 |

Balance |

Features

- High strength to 750°F

- Excellent general corrosion resistance

- High strength-to-weight ratio

Applications

- Aerospace, turbine engine and airframe applications

- Fasteners

- Medical and dental implants

- High performance Automotive

Physical Properties

Density: 0.160 lb/inch3

Melting Range: 2920 – 3020°F

Beta Transus: 1825± 25°F

|

Temperature, °F |

70 |

200 |

400 |

600 |

|

Coefficient of Thermal Expansion, in/in°F x 10-6 |

- |

5.3 |

5.4 |

5.5 |

|

Thermal Conductivity, |

4.0 |

4.3 |

5.2 |

6.1 |

|

Modulus of Elasticity, |

16.7 |

16.0 |

15.0 |

14.0 |

Mechanical Properties

Specified, STA sheet & plate

|

Tensile Strength, ksi |

0.2% Yield Strength, ksi |

Elongation in 2″, % |

|

170 |

160 |

10 |

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

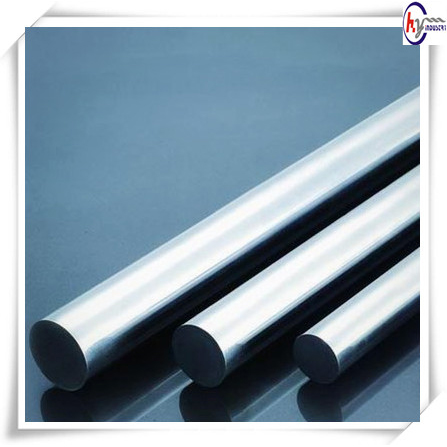

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

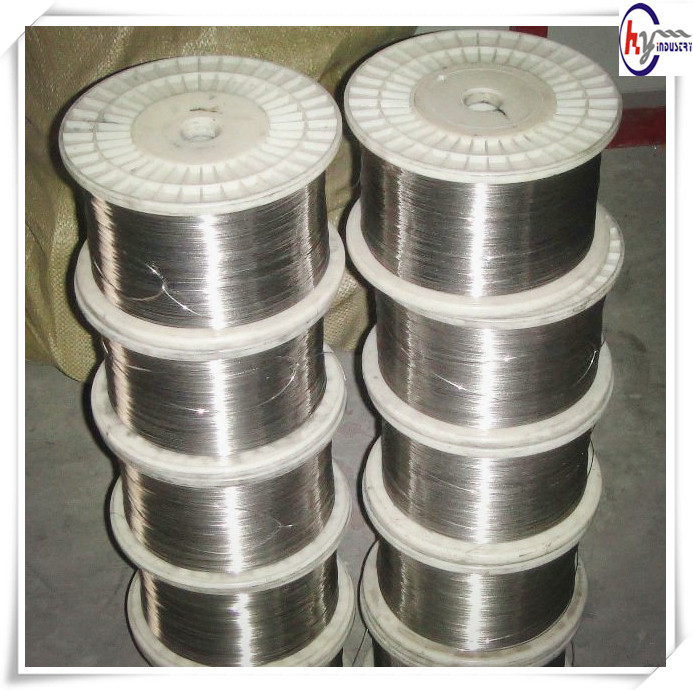

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

This is our 4000 watt Co2 laser slicing process. We can cut Stainless Steel and alloys to .five hundred”, Steel and metal alloys to .750″ and aluminum to .375″. Equally our devices have big bed dimensions, just one is sixty” x 120″ and the 3000 watt is seventy eight” x 157″. Equally devices have automatic loading and shuttle tables for prototyping to manufacturing.

Riporto(placcatura)con filo Nimonic 80 dia. one.2 eseguito con inverter multiprocesso Weldtronic Synertech 8004 Digit in pulsato sinergico.

NB .Il lampeggio dell’arco è presente solo nella ripresa effettuata dalla fotocamera digitale usata probabilmente a causa di interferenza con l’intenso arco luminoso.

Details: belda1@tiscali.it