High Efficiency Factory Nickel Alloy Hastelloy X UNS N06002 to San Diego Factories

Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction for High Efficiency Factory Nickel Alloy Hastelloy X UNS N06002 to San Diego Factories, We sincerely welcome domestic and foreign merchants who calls, letters asking, or to plants to negotiate, we will offer you quality products and the most enthusiastic service,We look forward to your visit and your cooperation.

HY HX Material grades and equivalents

Hastelloy X / GB GH3536&GH536/UNS N06002 / SEW VDIUV W.Nr.2.4613 / AFNOR NC22FeD

| HY HX | ||||||||||||||||

| UNS | Trademark | W.Nr | ||||||||||||||

| N06002 | HY HX | 2.4613 | ||||||||||||||

| HY HX Chemical compostion: | ||||||||||||||||

| Alloy | % | Ni | Cr | Fe | C | Mn | Si | Cu | S | B | Ti | P | Co | W | Mo | Al |

| HY HX | Min. | balance | 20.5 | 17 | 0.05 | 0.5 | 0.2 | 8 | ||||||||

| Max. | 23 | 20 | 0.15 | 1 | 1 | 0.5 | 0.015 | 0.01 | 0.15 | 0.025 | 2.5 | 1 | 10 | 0.5 | ||

| HY HX Physical properties: | ||||||||||||||||

| Density | 8.28 g/cm3 | |||||||||||||||

| Melting Point | 1295-1381 ℃ | |||||||||||||||

Hastelloy X Characteristic:

Good oxidation and corrosion resistance. Below 900 °C with middle elevated temperature stress rupture and creep rupture strength; good formability with cold working and hot working and excellent welding fabrication.

Hastelloy X Applied field:

Aero-engine combustion chamber and other parts used at elevated temperatures,long term usage below 900°C,short term usage temperature can reach 1080°C.

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

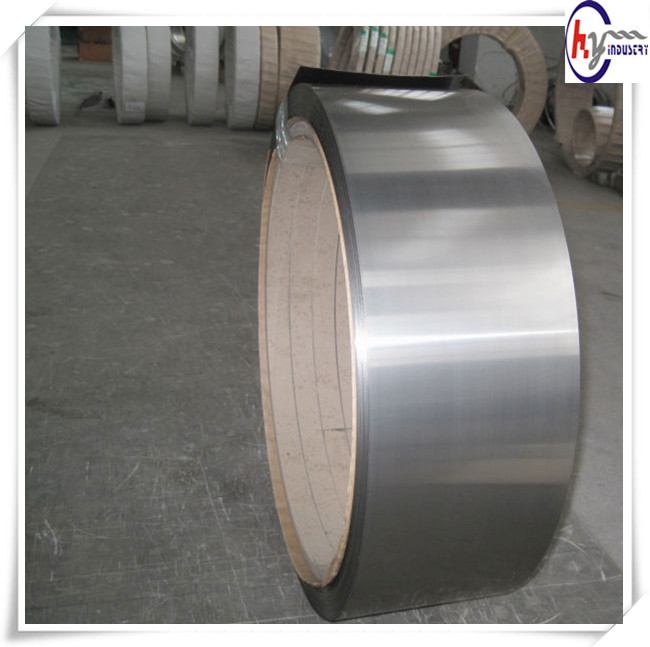

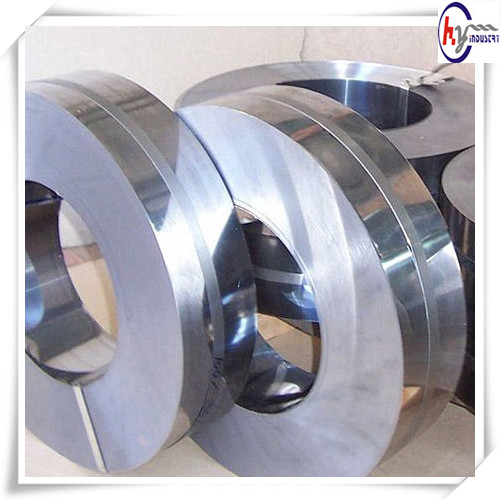

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

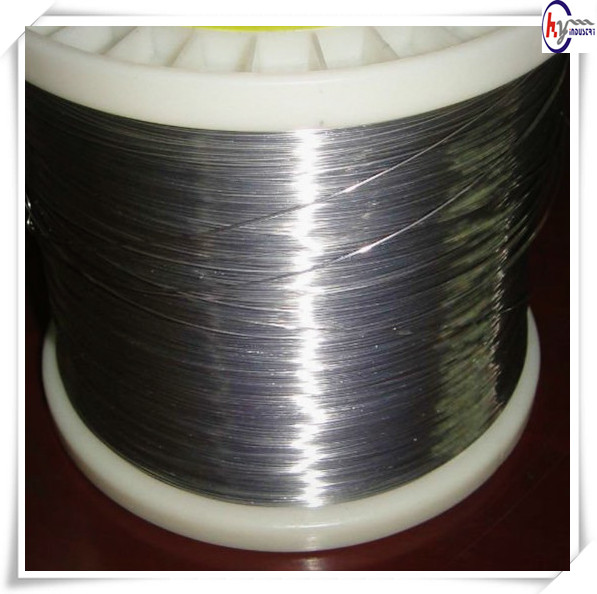

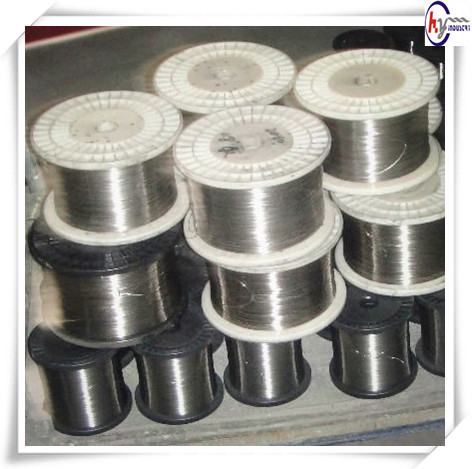

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

http://www.weldingtipsandtricks.com/metals-and-how-to-weld-nickel.html

How to weld nickel alloys like hastelloy, inconel, etc. Nickel alloys have a low thermal conductivity and so limiting heat input and using lower amperage than would be used for stainless is one key to making good nickel alloy welds.

Supplier foil、strip、sheet、coil、plate、wire、rod、bar、tube、pipe、flat ribbon、Profiled wire…

BuildingNo.1,Third Industrial District XiTou Village SongGang Town Bao’An District ShenZhen City GuangDong Province China