High Performance Nickel Alloy Hastelloy C UNS N06003 Manufacturer in Malawi

Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction for High Performance Nickel Alloy Hastelloy C UNS N06003 Manufacturer in Malawi, Competitive price with high quality and satisfying service make us earned more customers.we wish to work with you and seek common development.

HY HC Chemical composition

| Alloy |

% |

Ni |

Cr |

Mo |

Fe |

W |

Co |

C |

Mn |

Si |

V |

P |

S |

|

C |

Min. |

balance |

14.5 |

15 |

4 |

3 |

|||||||

|

Max. |

16.5 |

17 |

7 |

4.5 |

2.5 |

0.08 |

1 |

1 |

0.35 |

0.04 |

0.03 |

||

|

C22 |

Min. |

balance |

20 |

12.5 |

2 |

2.5 |

|||||||

|

Max. |

22.5 |

14.5 |

6 |

3.5 |

2.5 |

0.02 |

0.5 |

0.08 |

0.35 |

0.02 |

0.02 |

HY HC Physical properties

|

Density |

8.9 g/cm3 |

|

Melting point |

1325-1370 °C |

HY HC Alloy minimum mechanical properties in the room temperature

| Alloy state |

Tensile strength Rm N/mm2 |

Yield strength R P 0.2 N/mm2 |

Elongation A 5 % |

|

Hastelloy C22 |

690 |

283 |

40 |

Characteristic as below

HY HC is a omnipotent of nickel, chromium and molybdenum mixed alloy, with better corrosion resistance performance than other alloys, for example, Hastelloy C276 alloy, C4 alloy and 625 alloy. HY HC have a good resistance performance to pitting, crevice corrosion and stress corrosion cracking, have excellent inoxidability water medium performance, including the wet-chlorine, nitric acid or oxidizing acid mixed acid with chloride ion. Meantime, HY HC possesses perfect resistance to reduction and oxidation of processing enviroments, then it can be used in some complicated environment or with many different manufacture target factory depend on the omnipotent performance. HY HC possess prominent resistance performance to different chemical environments, including strong oxidizing matter, such as iron chloride, copper chloride, chlorine, heat pollution liquid(organic and inorganic), formic acid, acetic acid, acetyl oxide, sea water and salting liquid and so on.

HY HC Metallurgical structure

HY HC is face-centered cubic lattice structure.

HY HC Corrosion resistance

HY HC alloy suit for many kinds of chemical process industry which contain the oxidizing medium and reductant. High molybdenum and chromium content make it can resist the chloride corrosion, and tungsten make this corrosion resistance better. HY HC is one of a few material that can resist the corrosion of moist chlorine, hypochlorite and chlorine dioxide, this alloyhave prominent corrosion resistanceto high concentration chlorate( iron chloride and copper chloride)

HY HC Application field

HY HC is widely used in the chemical field and petrifaction field, such as the element of chloride organic and catalyze system. This material especially suit for high temperature environments, impure inorganic acid and organic acid (such as formic acid and acetic acid), sea-water corrosion environments.

HY HC Other application field

1. Acetic acid/acetyl oxide

2.Acid dipping

3.Cellophane paper manufactures

4.Chloride system

5. Complicated mixed acid

6. Electrogalvanizing groove roller

7.Expansion bellows

8.Flue gas washer system

9.Geothermal well

10.Fluorine hydride furnace cleaner

11.Incineration cleaner system

12. Nuclear fuel regeneration

13. Pesticide manufacture

14.Phosphoric acid manufacture

15.Acid cleaning system

16.Plate heat exchanger

17. Selectivity filter system

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

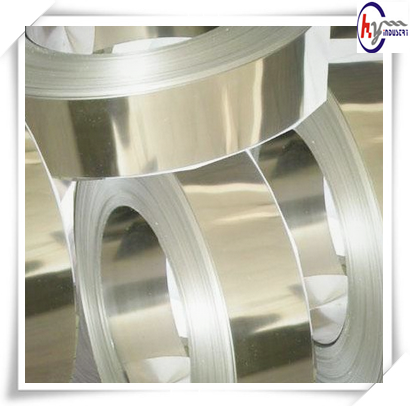

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

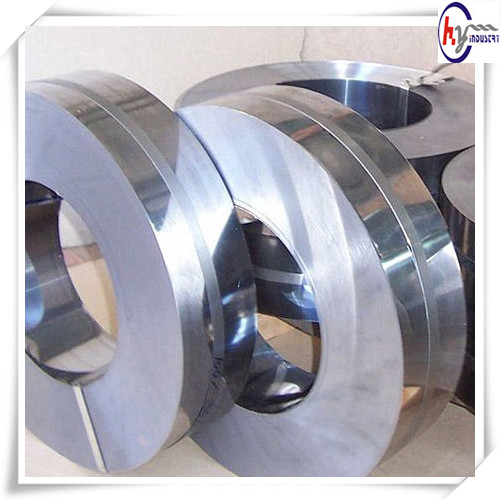

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

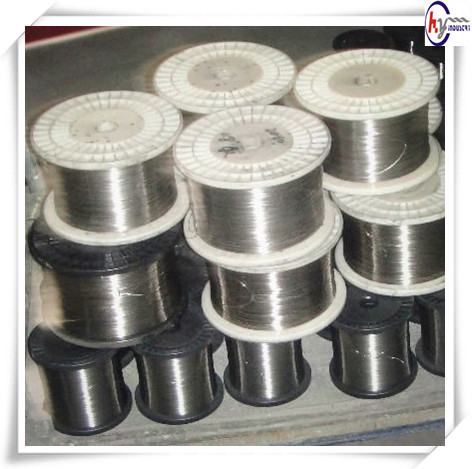

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

Substantial Temp Nickel Centered & Tremendous Alloys – Mechanical Homes Inconel Round Bar, Plate Sheet Offer – Inconel is designed of Mostly Nickel and a number of other aspects. The origin coming from Supernovas. Inconel is a Tremendous Alloy and Michlin Metals sells Inconel Round Bar, Hex Bar, Flat Bar, Plate, Sheet, Tube and Pipe.

Inconel 718, The Severe Metal Alloy. http://www.techsteel.web/alloy/nickel/inconel-718

Turbine Blades have revolutionized air vacation and electricity era.

Hundreds of slim precision blades spinning at a hundred,000 RPM have to have a materials that can stand up to excessive disorders.

Inconel 718 is a distinctive metal alloy that can stand up to excessive temperatures from -423° to 1300°F

This alloy is aged hardened, making it possible for it to be welded without having hardening for the duration of heating and cooling.

The improvement of Inconel began in the fifties for use in vital steam line plants. Originally used for armed service programs it was later on adopted by the professional sector.

Inconel 718‘s tolerance for excessive temperature make it specially perfectly suited for programs such as

turbine blades

nuclear electricity plants, and

aerospace programs. It was used in the space shuttles high force pump.

AMS 5589 | AMS 5596 | AMS 5597 | AMS 5663 | AMS 5664

For extra inconel 718 details take a look at techsteel.web

Tech Steel provides Specialty Alloys and Supplies.

Check out www.techsteel.web or phone 1-631-223-7638