High Quality for Iron alloy Stainless Steel 17-4PH for Swansea Manufacturer

It adheres to the tenet "Honest, industrious, enterprising, innovative" to develop new products constantly. It regards customers, success as its own success. Let us develop prosperous future hand in hand for High Quality for Iron alloy Stainless Steel 17-4PH for Swansea Manufacturer, We fully welcome customers from all over the world to establish stable and mutually beneficial business relationships, to have a bright future together.

|

HY 17-4PH Material grades and equivalents |

|

||

|

UNS |

AISI/ASTM |

JIS |

W.Nr |

|

S17400 |

630,17-4PH |

SUS630 |

1.4542 |

|

HY 17-4PH Chemical composition: |

|

|

|

|

|

|

|

|

|||

|

Alloy |

% |

Ni |

Cr |

Fe |

C |

Mn |

Si |

S |

Cu |

Nb |

P |

|

HY 17-4PH |

Min. |

3 |

15.5 |

balance |

|

|

|

|

3 |

0.15 |

|

|

Max. |

5 |

17.5 |

0.07 |

1 |

1 |

0.03 |

5 |

0.45 |

0.035 |

||

|

HY 17-4PH Physical properties |

||

|

Density |

7.78/cm3 |

|

|

Melting point |

1400-1440 °C |

|

|

HY 17-4PH Minimum mechanical properties in the room temperature |

||||||

|

Status |

Tensile strength |

Yield strength |

Elongation |

HRC(HBS) |

|

|

|

Rm N/mm² |

Rp0.2 N/mm² |

A5 % |

|

|

||

|

480°C age |

≥1310 |

≥1180 |

≥10 |

≥40 |

|

|

|

550°C Age |

≥1060 |

≥1000 |

≥12 |

≥35 |

|

|

|

580°C age |

≥1000 |

≥865 |

≥13 |

≥31 |

|

|

|

620°C age |

≥930 |

≥325 |

≥16 |

≥28 |

|

|

|

HY 17-4PH Characteristic: |

|

|

|

|

|

||

|

High strength and hardness, good welding performance and corrosion resistance |

|||||||

|

|

|

|

|

|

|

|

|

|

HY 17-4PH Application range and field: |

|

|

|

|

|||

|

Used in components with high strength and corroson resistance |

|

||||||

| Regular shape for all kinds of alloys |

|||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

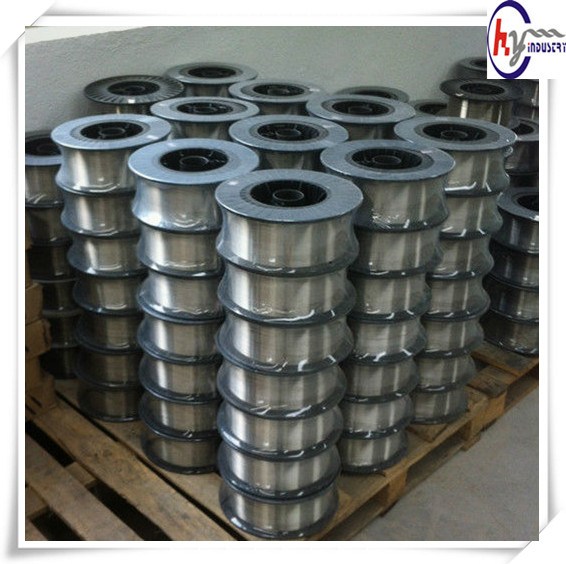

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

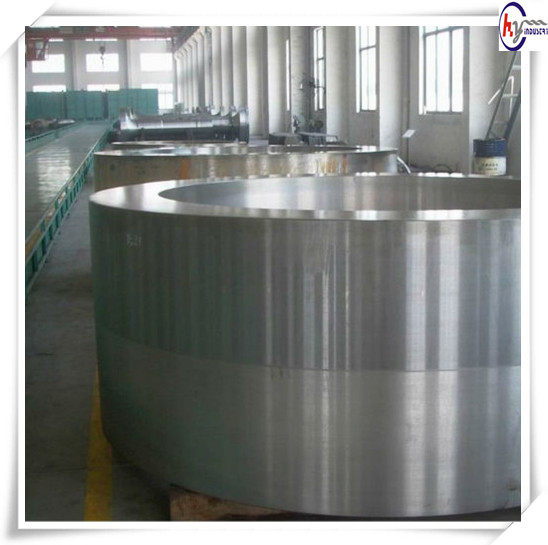

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

Riporto(placcatura)con filo Nimonic 80 dia. one.2 eseguito con inverter multiprocesso Weldtronic Synertech 8004 Digit in pulsato sinergico.

NB .Il lampeggio dell’arco è presente solo nella ripresa effettuata dalla fotocamera digitale usata probabilmente a causa di interferenza con l’intenso arco luminoso.

Details: belda1@tiscali.it

Inconel – Nickel Dependent Super Alloy – 600, 625, 718, X-750 Qualities and Programs August 2013 Inconel is a tremendous alloy and mixes effectively with Copper. Inconel arrives in a lot of varieties: Round Bar, Plate, Sheet, Pipe, Tube. Inconel is hard to machine for the reason that it perform hardens, Inconel 625 can be welded a bit.