Hot sale reasonable price Cobalt Alloy Haynes 188 Udimet alloy 188 UNS R30188 for Madagascar Manufacturers

Our company puts emphasis on the management, the introduction of talented personnel, and the construction of staff building, trying hard to improve the quality and liability consciousness of staff members. Our company successfully attained IS9001 Certification and European CE Certification of Hot sale reasonable price Cobalt Alloy Haynes 188 Udimet alloy 188 UNS R30188 for Madagascar Manufacturers, If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

HY 188 Material grades and equivalents: Udimet alloy 188;Werkstoff 2.4683;Alloy 188;Inconel alloy 188; Haynes Alloy 188;UNS R30188

HY 188 is a cobalt base superalloy with a unique combination of high temperature strength and oxidation resistance, along with adequate ductility after prolonged exposure to the 1400-1600°F temperature range.Cobalt alloys have an herent advantage over the nickel base grades in high temperature creep.Alloy 188 is solid solution strengthened by a 14% tungsten addition, and further by M6C and M23C6 carbides

HY 188 Chemical composition:

| Alloy | Cr | Ni | Co | W | La | B | C | Fe | Mn | Si | P | S | |

|

188 |

MIN | 20.0 | 20.0 | - | 13.0 | 0.02 | - | 0.05 | - | - | 0.2 | - | - |

| MAX | 24.0 | 24.0 | Balance | 16.0 | 0.12 | 0.015 | 0.015 | 3.0 | 1.25 | 0.5 | 0.02 | 0.015 |

HY 188 Physical properties:

| Density | 9.14 g/cm3 |

| Melting point | 1300℃-1330 ℃ |

HY 188 alloy sheet mechanical properties in the room temperature:

| Alloy Status | Tensile strength Rm N/mm² |

Yield strengthRP0.2 N/mm² | Elongation A5 % |

| Solution Treatment | 963 | 446 | 55 |

HY 188 Applications Fileds:

This alloy useful in gas turbine applications such as combustors, flame holders, liners and transition ducts.

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

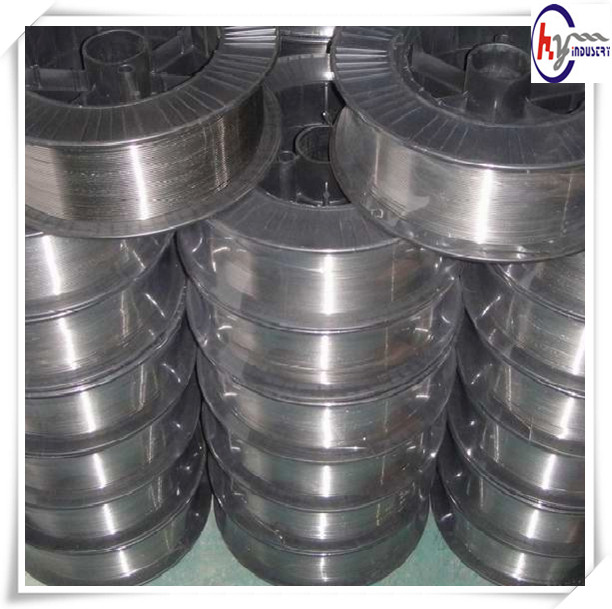

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

Welding Inconel 718

Inconel – Nickel Dependent Super Alloy – 600, 625, 718, X-750 Qualities and Programs August 2013 Inconel is a tremendous alloy and mixes effectively with Copper. Inconel arrives in a lot of varieties: Round Bar, Plate, Sheet, Pipe, Tube. Inconel is hard to machine for the reason that it perform hardens, Inconel 625 can be welded a bit.