Hot sale reasonable price Cobalt Alloy Haynes 188 Udimet alloy 188 UNS R30188 Manufacturer in Mali

We are proud of the high customer satisfaction and wide acceptance due to our persistent pursuit of high quality both on product and service for Hot sale reasonable price Cobalt Alloy Haynes 188 Udimet alloy 188 UNS R30188 Manufacturer in Mali, We encourage you to make contact as we are looking for partners in our venture. We are sure you will find doing business with us not only fruitful but also profitable. We are ready to serve you with what you require.

HY 188 Material grades and equivalents: Udimet alloy 188;Werkstoff 2.4683;Alloy 188;Inconel alloy 188; Haynes Alloy 188;UNS R30188

HY 188 is a cobalt base superalloy with a unique combination of high temperature strength and oxidation resistance, along with adequate ductility after prolonged exposure to the 1400-1600°F temperature range.Cobalt alloys have an herent advantage over the nickel base grades in high temperature creep.Alloy 188 is solid solution strengthened by a 14% tungsten addition, and further by M6C and M23C6 carbides

HY 188 Chemical composition:

| Alloy | Cr | Ni | Co | W | La | B | C | Fe | Mn | Si | P | S | |

|

188 |

MIN | 20.0 | 20.0 | - | 13.0 | 0.02 | - | 0.05 | - | - | 0.2 | - | - |

| MAX | 24.0 | 24.0 | Balance | 16.0 | 0.12 | 0.015 | 0.015 | 3.0 | 1.25 | 0.5 | 0.02 | 0.015 |

HY 188 Physical properties:

| Density | 9.14 g/cm3 |

| Melting point | 1300℃-1330 ℃ |

HY 188 alloy sheet mechanical properties in the room temperature:

| Alloy Status | Tensile strength Rm N/mm2 |

Yield strengthRP0.2 N/mm2 | Elongation A5 % |

| Solution Treatment | 963 | 446 | 55 |

HY 188 Applications Fileds:

This alloy useful in gas turbine applications such as combustors, flame holders, liners and transition ducts.

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

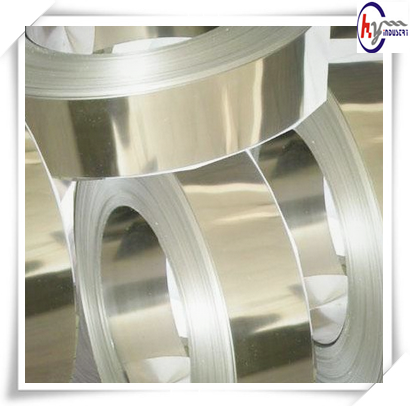

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

Inconel 718, The Severe Metal Alloy. http://www.techsteel.web/alloy/nickel/inconel-718

Turbine Blades have revolutionized air vacation and electricity era.

Hundreds of slim precision blades spinning at a hundred,000 RPM have to have a materials that can stand up to excessive disorders.

Inconel 718 is a distinctive metal alloy that can stand up to excessive temperatures from -423° to 1300°F

This alloy is aged hardened, making it possible for it to be welded without having hardening for the duration of heating and cooling.

The improvement of Inconel began in the fifties for use in vital steam line plants. Originally used for armed service programs it was later on adopted by the professional sector.

Inconel 718‘s tolerance for excessive temperature make it specially perfectly suited for programs such as

turbine blades

nuclear electricity plants, and

aerospace programs. It was used in the space shuttles high force pump.

AMS 5589 | AMS 5596 | AMS 5597 | AMS 5663 | AMS 5664

For extra inconel 718 details take a look at techsteel.web

Tech Steel provides Specialty Alloys and Supplies.

Check out www.techsteel.web or phone 1-631-223-7638

http://www.weldingtipsandtricks.com/metals-and-how-to-weld-nickel.html

How to weld nickel alloys like hastelloy, inconel, etc. Nickel alloys have a low thermal conductivity and so limiting heat input and using lower amperage than would be used for stainless is one key to making good nickel alloy welds.