Hot-selling attractive Titanium alloy 6Al-4V UNS R56400 Wholesale to Finland

We stick to our enterprise spirit of "Quality, Efficiency, Innovation and Integrity". We aim to create more value for our customers with our rich resources, advanced machinery, experienced workers and excellent services for Hot-selling attractive Titanium alloy 6Al-4V UNS R56400 Wholesale to Finland, sincerely look forward to serving you in the near future. You are sincerely welcome to visit our company to talk business face to face with each other and establish long-term co-operation with us!

HY Titanium 6-4 Material grades and equivalents

6-4 Titanium, 6-4, Ti 6-4, UNS R56400

Introduction

HY Titanium 6-4 is the most widely used of all the alpha-beta titanium alloys. It is typically used in the annealed condition, at service temperatures through 750°F. However it may be heat treated for high strength in sections under 4″ thick. Hardenability is limited and sections over one inch may not develop full properties. HY Titanium 6-4 is welded with matching or with ELI filler wire.

Mill anneal: 1300-1450°F 2 hours, air cool. Recrystallization anneal bar for better ductility and fatigue strength, 1750°F 2 hours, furnace cool.

For maximum fracture toughness and SCC resistance: Beta anneal 1950°F 1-2 hours, water quench. Then age 1150-1300°F 2 to 4 hours, air cool.

For maximum strength: solution-treated and aged (STA) condition is: For sheet, 1675-1725°F 5 to 25 minutes, water quench. Age 975°F 4 to 6 hours, air cool. For bars and forgings, 1675-1725°F 1 hour, water quench. Age 975-1025°F 3 hours, air cool.

For increased fracture toughness, but lower tensile strength: precipitation treat (overage) 1150-1250°F 4 hours, air cool. Stress relief annealing is commonly 1000-1200°F 1 to 4 hours, air cool.

HY Titanium 6-4 is resistant to general corrosion but may be quickly attacked by environments that cause breakdown of the protective oxide. These include hydrofluoric (HF), hydrochloric (HCl), sulfuric and phosphoric acids. Inhibitors may help for the last four but not for HF. HY Titanium 6-4 resists attack by pure hydrocarbons, and most chlorinated and fluorinated hydrocarbons (provided water has not caused formation of small amounts of HCl and HF).

HY Titanium 6-4 is susceptible to chloride stress corrosion cracking (SCC), although being among the better of the titanium alloys in this regard. For marine environments silver plated bolts are not used, as silver bonds easily with chlorine in this environment. HY Titanium 6-4 is also susceptible to SCC in environments such as methyl alcohol, red fuming HNO3, and N2O4. In the case of red fuming nitric acid, the problem is limited to environments containing less than 1.5% water, or more than 6% NO2. Failure in N2O4 has occurred when oxygen and chlorides were present as impurities.

Chemistry Composition

|

Al |

V |

C |

N |

O |

H |

Fe |

Y |

Others, |

Others, |

Ti |

|

|

MIN |

5.5 |

3.5 |

– |

– |

– |

– |

– |

– |

– |

– |

– |

|

MAX |

6.75 |

4.5 |

0.08 |

0.05 |

0.2 |

0.0125 |

0.3 |

0.005 |

0.1 |

0.4 |

Balance |

Features

High strength to 600°FExcellent general corrosion resistanceHigh strength-to-weight ratio

Applications

Turbine blades, discs and ringsAircraft structural componentsWeapons structural componentsFastenersMedical and dental implantsHand toolsSporting equipmentChemical process equipment

Physical Properties

Density: 0.160 lb/inch3

Melting Range: 2929 – 3020°F

Beta Transus: 1825± 25°F

|

Temperature, °F |

70 |

200 |

400 |

600 |

|

Coefficient of Thermal Expansion, in/in°F x 10-6 |

- |

5.3 |

5.4 |

5.5 |

|

Thermal Conductivity, |

4.0 |

4.3 |

5.2 |

6.1 |

|

Modulus of Elasticity, |

16.7 |

16.0 |

15.0 |

14.0 |

Mechanical Properties

Specified, AMS 4911, annealed sheet & plate

|

Anneal 1300°F, Air Cool |

Anneal 1300°F, Solution anneal 1750°F , Age 1000°F |

|

|

Ultimate Tensile Strength, ksi |

138-155 |

150-172 |

|

0.2% Yield Strength, ksi |

128-147 |

137-156 |

|

Elongation, % |

15-20 |

15-17 |

|

Reduction of Area, % |

38-51 |

41-46 |

Typical Tensile Strength and Fracture Toughness, Various Heat Treatments for Flat-rolled Products (MCIC-HB-02 1985 reprint)

|

0.2% Yield Strength, ksi |

Fracture Toughness K1C, ksi √in |

|

|

Annealed |

132 |

128 |

|

Beta Annealed (plate) |

131 |

134 |

|

Beta STA 1250°F b |

128 |

150 |

|

Beta STA 1000°F b |

143 |

120 |

|

STA 1250°Fc |

137 |

105 |

|

STA 1000°Fc |

159 |

80 |

(a) Directional variations,

(b) Beta heat treated followed by solution treating and overaging 1250 F, or aging 1000 F

(c) Solution treating and overaging 1250 F, or aging 1000 F

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

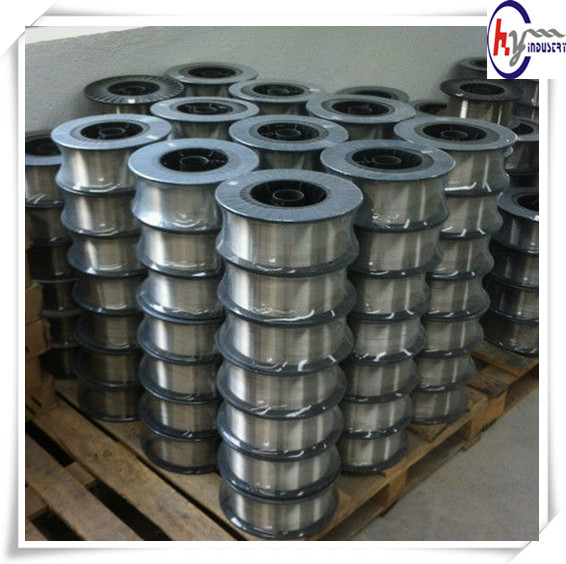

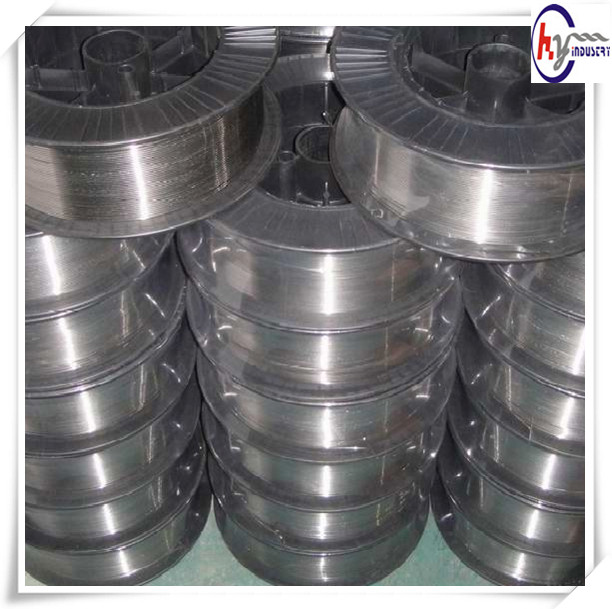

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

» Metal Tubes India is a GOVT. OF INDIA Acknowledged STAR EXPORT Dwelling & PED Accredited Maker

» Metal Tubes India is winner of All India Award for export excellence for 6 Consecutive Many years

» Metal Tubes India is an ISO 9001,ISO 14001,OHSAS 18001 Accredited company, our international CRISIL Ranking is SE 2B

» Metal Tubes India is European Force Machines Directive PED-97/23/EC qualified company

Ni 72., Cr fifteen.5, Fe 8. Mn 1. C .fifteen Cu .5 Si .5 S .015

Significant Efficiency Alloys stocks and produces this grade in the adhering to forms: Bar, wire, sheet, plate, coil, fasteners and forgings. Ask for quote on this grade.

Alloy 600 is a nickel-chromium alloy built for use from cryogenic to elevated temperatures in the selection of 2000 deg F(1093 deg C). The superior nickel material of the alloy allows it to retain substantial resistance less than lessening conditions and makes it resistant to corrosion by a range of natural and inorganic compounds. The nickel material gives it exceptional resistance to chloride-ion pressure-corrosion cracking and also offers exceptional resistance to alkaline options.

Inconel 600 Tube

ASME SB-163 ASME SB-516 ASME SB751 AMS 5580

UNS N06600 also offered in numerous forms like cap, elbow, erw pipes, fasteners, fittings, flange, plate, reducer, spherical bar, seamless pipes, sheet, tee and tube at industrial charge.

+ for extra info & specification about Inconel 600 remember to check out

http://www.steeltubesindia.internet/

I am earning my own wedding day band from Inconel X-750 just to be diverse. The material is a agony to do the job with thanks to the superior nickel/chromium articles. The lathe is a LeBlond “dual generate” with an Aloris-copy device article. I built an adapter for the one.25″ boring bar socket to sleeve it down to a 5/8″ side-lock drill shank. I utilised an indicator to sweep the device holder, inserting it instantly on center. The drill is a Seco CrownLoc As well as with .625″ tip, running at around 80sfm, hand feed with plenty of stress, and drenched in reducing oil (not demonstrated in pic). Chips had been astonishingly limited of course, I had to withdrawal the device numerous moments to eliminate chips, due to the fact they weren’t becoming flushed by coolant.