Hot Selling for Titanium alloy 10V-2Fe-3Al UNS R56410 Factory in Sierra Leone

Our goal is to provide high quality products at competitive prices, and top-notch service to customers around the world. We are ISO9001, CE, and GS certified and strictly adhere to their quality specifications for Hot Selling for Titanium alloy 10V-2Fe-3Al UNS R56410 Factory in Sierra Leone, Welcome to build the well and long standing business relationships with our company to create a glorious future together .customers' satisfaction is our eternal pursuit

HY Titanium 10-2-3 Material grades and equivalents

10-2-3 Titanium, UNS R56410

Introduction

HY Titanium 10-2-3 is a near beta alloy developed as a high strength forging alloy. This grade provides the best combination of strength and toughness of the commercially available titanium alloys. Its strength permits about a 27% weight savings when compared to Ti-6Al-4V. At the 180 ksi tensile strength level, the K1cvalue is 40 ksi-in minimum. Solution treated and aged material possesses excellent resistance to stress corrosion cracking, typically K1scc being greater than 0.8 K1c. Solution treated material should not be subject to long term exposure in the 500-800°F range. This could result in high strength but low ductility.

High strength condition: Solution treat 60-100°F below the beta transus (typically 1460-1480°F), not less than 30 minutes, water quench. Age 900-975°F not less than 8 hours, air cool. For lower strength, overage in the 950-1150°F range. This alloy is deep hardenable, capable of high strengths in sections up to approximately 4″ thick.

This grade is usually supplied as billet or bar, finish rolled or forged in the alpha-beta field. For the high strength condition, the forging is usually given a pre-form forge above the beta transus, followed by 15-25% reduction below the beta transus.

Chemistry Composition

|

V |

Al |

Fe |

C |

N |

O |

H |

Y |

Others, |

Others, |

Ti |

|

|

MIN |

9.0 |

2.6 |

1.6 |

- |

- |

- |

- |

- |

- |

- |

- |

|

MAX |

11.0 |

3.4 |

2.22 |

0.05 |

0.05 |

0.13 |

0.015 |

0.005 |

0.10 |

0.30 |

Balance |

Features

High strength and toughnessWeight savings when compared to Ti-6Al-4VExcellent resistance to stress corrosion cracking

Applications

Hand and die forgingsAircraft landing gearGolf club driver faces

Physical Properties

Density: 0.168 lb/inch3

Nominal Beta Transus: 1470°F

Poisson’s ratio: 0.32

Thermal Expansion: 75-800°F, 5.4×10-6 in/in°F

Tensile Modulus: 15.9×106 psi

Modulus: 16.2×106 psi

* 70°F to indicated temperature.

Mechanical Properties

Minimum Mechanical Properties AMS 4984, solution treated and aged

|

Ultimate Tensile Strength, ksi |

173 |

|

Ultimate Tensile Strength, ksi |

160 |

|

0.2% Yield Strength, ksi |

4 |

|

Reduction of Area, % |

Report |

|

fracture toughness, k1C |

40 ksi |

AMS 4987, single solution heat treat & overage

|

Ultimate Tensile Strength, ksi |

140 |

|

0.2% Yield Strength, ksi |

130 |

|

Elongation, % |

8 |

|

Reduction of Area, % |

20 |

|

fracture toughness, k1C |

80 ksi |

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

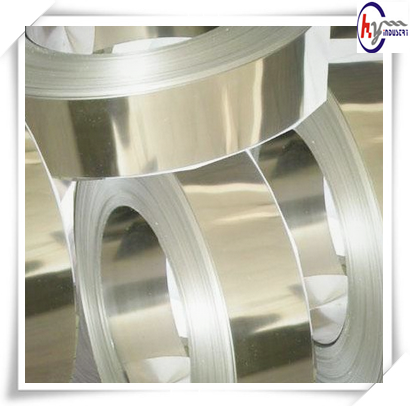

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

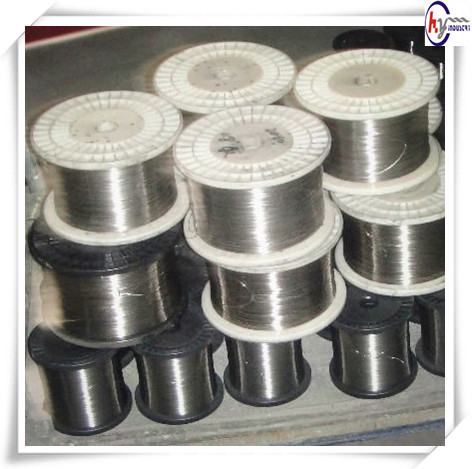

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

http://www.weldingtipsandtricks.com/metals-and-how-to-weld-nickel.html

How to weld nickel alloys like hastelloy, inconel, etc. Nickel alloys have a low thermal conductivity and so limiting heat input and using lower amperage than would be used for stainless is one key to making good nickel alloy welds.

http://www.GovLiquidation.com – This 69,560 lbs of Inconel 625 scrap steel has been bought. To look at a current checklist of obtainable scrap steel material, pay a visit to http://bit.ly/jL05Ke currently!

This Inconel was in matrix roll kind and free in pans. This good deal of significant temp alloy scrap steel consisted of Carbon: max .10%, Chromium: min 20% max 23%, Iron: max 5%, Silicon: max .fifty%, Manganese: max .fifty%, Sulfur: max .015%, Phosphorus: max .015%, Molybdenum: min 8% max 10%, Titanium: max .forty%, Nickel: Stability.

This material was positioned in Anniston, AL.

To look at a current checklist of obtainable scrap steel material, pay a visit to http://bit.ly/jL05Ke currently!