HY 738LC/ Inconel 738LC

HY 738LC Material grades and equivalents

Inconel 738LC

Short Introduction:

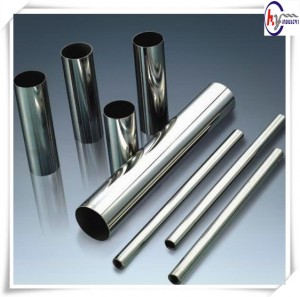

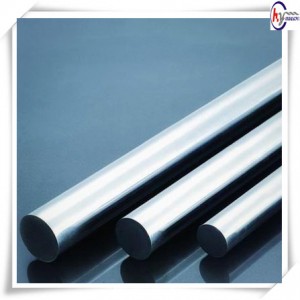

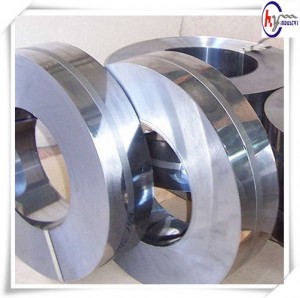

HY 783LC is a precipitation hardenable nickel-base alloy with superior corrosion resistance and high temperature creep-rupture strength. HY 738 LC is used in gas turbine blades and other high-temperature industrial applications. HY Industry Co. manufactures HY 783LC in varying compositions and forms such as powder, plate, rod, wire, and sputtering target.

HY 738LC Chemical composition:

|

Element |

C |

Mn |

Si |

W |

S |

P |

Cr |

Mo |

Ai+Ti |

|

Min |

0.09 |

- |

- |

2.4 |

- |

- |

15.7 |

1.5 |

6.5 |

|

Max |

0.13 |

0.2 |

0.3 |

2.8 |

0.015 |

0.015 |

16.3 |

2.0 |

7.2 |

|

Element |

Cb |

Ti |

Ai |

B |

Zr |

Co |

Ta |

Fe |

Ni |

|

Min |

0.6 |

3.2 |

3.2 |

0.007 |

0.03 |

8.0 |

1.4 |

- |

Balance |

|

Max |

1.1 |

3.7 |

3.7 |

0.012 |

0.08 |

9.0 |

2.0 |

0.35 |

Heat Treatment Procedure

| Precipitation Hardening | |||

| Solution Annealing | Temperature | Holding time | Remarks |

| 1120 oC | 2 hours | 25-40 oC ⁄ min to below 800 oC | |

| Aging | Temperature | Holding time | Remarks |

| 845 oC | 24 hours | Air cool | |

Physical properties:

Tensile :

| Temperature(℃) | Yield, N/mm2min | UTS, N/mm2min | Elongation, minA5 (%) | Reduction ofArea, min (%) |

| 25 |

792 |

895 | 4 | 5 |

| 650 |

690 |

895 | 4 | 5 |

Creep Rupture Properties:

| Temperature (℃) | Stress (N/mm2) | Life (Hours) | Elongation (A4) (%) | Reduction of Area (Z)(%) |

| 982 | 152 | ≥ 30 | ≥ 5 | ≥ 10 |

Write your message here and send it to us