Low price for Nickel Alloy Inconel 617 UNS N06617 in Congo

To be the stage of realizing dreams of our employees! To build a happier, more united and more professional team! To reach a mutual benefit of our customers, suppliers, the society and ourselves for Low price for Nickel Alloy Inconel 617 UNS N06617 in Congo, With the aim of "compete with good quality and develop with creativity" and the service principle of "take customers' demand as orientation", we will earnestly provide qualified products and good service for domestic and international customers.

HY617 Material grades and equivalents

Inconel 617/ UNS N07617 / SEW VDIUV W.Nr.2.4663 NiCr23Co12Mo / AFNOR NC22KDA

HY 617 is a solid-solution, strengthened, nickel-chromium-cobalt- molybdenum alloy with an exceptional combination of high-temperature strength and oxidation resistance. The alloy also has excellent resistance to a wide range of corrosive environments, and it is readily formed and welded by conventional techniques.

The combination of high strength and oxidation resistance at temperatures over 1800°F (980°C) makes HY617 an attractive material for such components as ducting, combustion cans, and transition liners in both aircraft and land-based gas turbines.

HY 617 Chemical composition:

|

Alloy |

% |

Ni |

Cr |

Fe |

C |

Mn |

Si |

Mo |

Co |

Al |

Ti |

P |

S |

|

617 |

Min |

20 |

0.05 |

8 |

10.0 |

0.6 |

0.2 |

||||||

|

Max |

Rest |

23 |

2.0 |

0.1 |

0.7 |

0.7 |

10.0 |

13.0 |

1.5 |

0.6 |

0.012 |

0.008 |

HY 617 Physical properties:

|

Density |

8.4 g/cm3 |

|

Melting Point |

1330-1380℃ |

Corrosion Resistance

elevated temperatures, those elements cause the formation of a thin, subsurface zone of oxide particles.

The zone forms rapidly upon exposure to high temperatures until it reaches a thickness of 0.001 to 0.002

in. (0.025 to 0.05 mm). The oxide zone provides the proper diffusion conditions for the formation of a

protective chromium oxide layer on the surface of the metal. It also helps to prevent spalling of the

protective layer.

HY 617 has excellent resistance to carburization. Table 9 compares alloy 617 and some other

carburization-resistant alloys in a gaseous carburizing environment at 2000°F (1095°C). The weight-gain

measurements indicate the amount of carbon absorbed during the test period. The composition of INCONEL alloy 617 includes substantial amounts of nickel, chromium, and aluminum for

a high degree of resistance to oxidation and carburization at high temperatures. Those elements, along

with the molybdenum content, also enable the alloy to withstand many wet corrosive environments.

Heat Treatment

HY 617 is normally used in the solutionannealed condition. That condition provides a coarse grain

structure for the best creep-rupture strength. It also provides the best bend ductility at room temperature. Solution

annealing is performed at a temperature of 2150°F (1175°C)for a time commensurate with section size.

Cooling should be by water quenching or rapid air cooling.

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

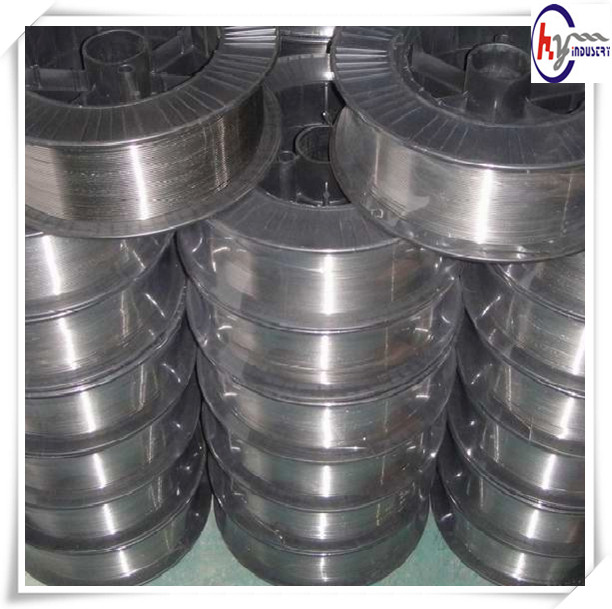

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

Metals playlist: https://www.youtube.com/playlist?record=PL64F10A579EB0A526

far more at http://scitech.quickfound.net/

Aluminum creation system like mining bauxite in Arkansas and Jamaica, transport Jamaican ore from Ocho Rios, reduction of the bauxite at vegetation in the US., and manufacturing of aluminum ingots and forming aluminum sheets and personalized parts. Animated intro is equivalent to present-day Fortunate Strike and Rheingold beer commercials.

“How aluminum contributes to everyday dwelling and national protection: appliances, packaging, airplanes, and so on. With fantastic quit-movement animation.”

Reupload of a previously uploaded film with enhanced online video & audio.

Public domain film from the Library of Congress Prelinger Archives, slightly cropped to take out uneven edges, with the component ratio corrected, and a single-move brightness-distinction-coloration correction & delicate online video noise reduction utilized.

The soundtrack was also processed with volume normalization, noise reduction, clipping reduction, and/or equalization (the resulting audio, while not ideal, is much significantly less noisy than the unique).

http://creativecommons.org/licenses/b…

http://en.wikipedia.org/wiki/Aluminium

Aluminium… is a silvery white member of the boron team of chemical aspects. It has the symbol Al, and its atomic variety is thirteen. It is not soluble in h2o beneath typical instances. Aluminium is the 3rd most considerable element (right after oxygen and silicon), and the most considerable steel, in the Earth’s crust. It would make up about 8% by bodyweight of the Earth’s sound floor. Aluminium steel is much too reactive chemically to manifest natively. As an alternative, it is discovered put together in more than 270 distinct minerals. The chief ore of aluminium is bauxite.

Aluminium is impressive for the metal’s very low density and for its skill to resist corrosion due to the phenomenon of passivation. Structural factors produced from aluminium and its alloys are vital to the aerospace sector and are significant in other places of transportation and structural resources. The most helpful compounds of aluminium, at least on a bodyweight foundation, are the oxides and sulfates…

Bodily

Aluminium is a soft, resilient, light-weight, ductile and malleable steel with appearance ranging from silvery to boring gray, relying on the floor roughness. Aluminium is nonmagnetic and does not simply ignite. A fresh film of aluminium film serves as a excellent reflector (around 92%) of noticeable light and an outstanding reflector (as much as 98%) of medium and much infrared radiation. The generate strength of pure aluminium is seven–11 MPa, even though aluminium alloys have generate strengths ranging from two hundred MPa to 600 MPa. Aluminium has about a single-3rd the density and stiffness of metal. It is simply machined, solid, drawn and extruded.

Corrosion resistance can be outstanding due to a slender floor layer of aluminium oxide that varieties when the steel is exposed to air, proficiently protecting against further oxidation. The strongest aluminium alloys are significantly less corrosion resistant due to galvanic reactions with alloyed copper. This corrosion resistance is also usually drastically decreased when lots of aqueous salts are current, specially in the presence of dissimilar metals…

Aluminium mirror end has the best reflectance of any steel in the two hundred–400 nm (UV) and the 3,000–10,000 nm (much IR) locations in the 400–seven hundred nm noticeable selection it is slightly outperformed by tin and silver and in the seven hundred–3000 (near IR) by silver, gold, and copper.

Aluminium is a excellent thermal and electrical conductor, possessing 59% the conductivity of copper, both of those thermal and electrical…

Aluminium varieties powerful chemical bonds with oxygen. In contrast to most other metals, it is tough to extract from ore, these kinds of as bauxite, due to the vitality essential to minimize aluminium oxide (Al2O3)…

Aluminium electrolysis with the Hall-Héroult system consumes a large amount of vitality, but substitute procedures ended up generally discovered to be significantly less feasible economically and/or ecologically…

In 2005, the People’s Republic of China was the leading producer of aluminium with pretty much a a single-fifth earth share, followed by Russia, Canada, and the Usa, experiences the British Geological Study…

http://en.wikipedia.org/wiki/Reynolds…

The Reynolds Metals Company was founded in 1919 as the U.S. Foil Company in Louisville, Kentucky by Richard S. Reynolds, Sr., a nephew of tobacco king R. J. Reynolds. To begin with, the new organization equipped guide and tin foil wrappers to cigarette and candy firms. In 1924, the U.S. Foil bought the maker of Eskimo Pies, which ended up wrapped in foil. In 1928, Reynolds bought Robertshaw Thermostat, Fulton Sylphon, and portion of Beechnut Foil, introducing them to U.S. Foil to make Reynolds Metals…

The organization started creating aluminum foil for packaging in 1926.

Supplier foil、strip、sheet、coil、plate、wire、rod、bar、tube、pipe、flat ribbon、Profiled wire…

BuildingNo.one,Third Industrial District XiTou Village SongGang Town Bao’An District ShenZhen Town GuangDong Province China