Manufacturer for Nickel Alloy Inconel 690 UNS N06690 Factory from Israel

With our excellent management, strong technical capability and strict quality control system, we continue to provide our clients with reliable quality, reasonable prices and excellent services. We aim at becoming one of your most reliable partners and earning your satisfaction for Manufacturer for Nickel Alloy Inconel 690 UNS N06690 Factory from Israel, We are confident to make great achievements in the future. We are looking forward to becoming one of your most reliable suppliers.

HY 690 Material grades and equivalents

Inconel 690 / UNS N06690 / W. Nr. 2.4642

HY 690 Chemical composition:

|

Type |

% Main Chemical Composition % |

|||||||

|

Ni |

Cr |

Fe |

Cu |

C |

Si |

Mn |

S |

|

|

HY 690 |

Rest |

27.0~31.0 |

7.0~11.0 |

≤0.05 |

≤0.05 |

≤0.5 |

≤0.5 |

≤0.015 |

HY 690 Physical properties:

|

Density |

Melting range |

Hardness |

|

|

8.73 |

1338~1380 |

HRC36 |

HY 690 Alloy minimum mechanical properties in the room temperature

|

Condition |

Tensile Strength |

Yield strength |

Elongation |

|

A 5 % |

|||

|

Solution |

690~738 |

334~372 |

44~50 |

HY 690 Characteristic as below

HY 690 alloy is a kind of nickel based wrought super alloy which has excellent resistance to many aqueous medium and ability of high temperature atmosphere erosion. It also has high strength , good stability and excellent characteristics for metallurgical processing.

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

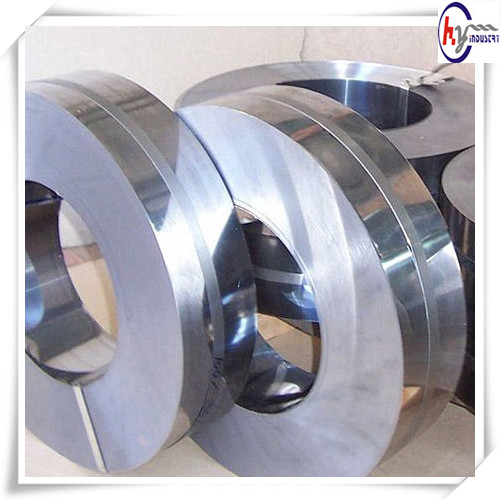

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

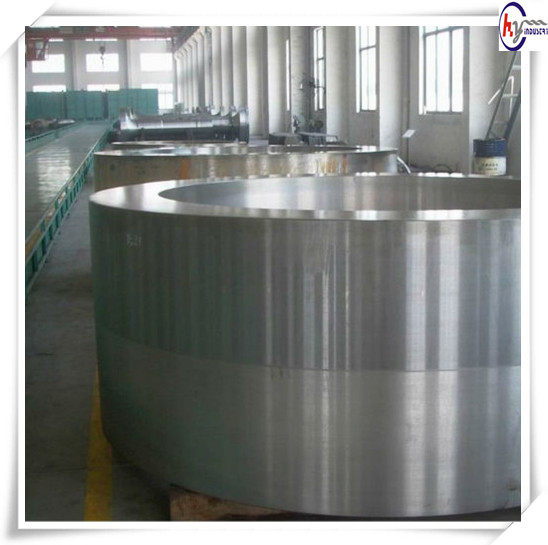

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

Check out additional TIG Welding Video clips from Weld.com:

http://www.weld.com/index.php/Mr-Tig-Blog/

Subscribe on YouTube and Never ever Miss a Video!

http://www.youtube.com/channel/UCM0kHJXSHR1k1wtLuliKmHg?sub_confirmation=one

Pay a visit to the Welding Discussion board to Carry on the Dialogue and Compete in Month to month Contests!

http://www.weld.com/index.php/Weekend-Warrior-Welding-Discussion board/groups.html

Fb: https://www.fb.com/WeldDotCom

Twitter: https://twitter.com/WeldDotCom

—————————————————————————–

Weld.com welding films are a collection of welding displays that are loaded with welding strategies, tricks and hints that will support you drop that perfect bead each individual time! Whether you are making an attempt to become far better in the locations of TIG Welding, MIG Welding, Adhere Welding or Slicing Weld.com has what you will need. All films are shot from “guiding the hood” so you can get the welders standpoint. In addition to exhibiting you how to weld, many periods we will clearly show you popular issues and how to steer clear of them.

New episodes each individual Friday!

Early launch on the discussion board!

http://www.weldingtipsandtricks.com/metals-and-how-to-weld-nickel.html

How to weld nickel alloys like hastelloy, inconel, etc. Nickel alloys have a low thermal conductivity and so limiting heat input and using lower amperage than would be used for stainless is one key to making good nickel alloy welds.