New Delivery for Cobalt Alloy Alloy L605 Haynes 25 UNS R30605 to United Arab emirates Importers

Our development depends on the advanced equipment, excellent talents and continuously strengthened technology forces. New Delivery for Cobalt Alloy Alloy L605 Haynes 25 UNS R30605 to United Arab emirates Importers, We will wholeheartedly welcome all clients in the industry both at home and abroad to cooperate hand in hand, and create a bright future together.

HY L605 Material grades and equivalents: Udimet alloy L605;Alloy L605;Cobalt alloy L605; Haynes 25;UNS R30605

Introduction:

HY L-605 is useful in gas turbine applications such as rings,blades and combustion chamber parts (sheet fabrications) and can also can be used in industrial furnace applications such as muffles or liners in high temperature kilns

HY L605 is a solid solution strengthened cobalt-chromium-tungstennickel alloy with excellent high-temperature strength and excellent oxidation resistance to 2000°F (1093°C). The alloy also offers good resistance to sulfidation and resistance to wear and galling.

HY L605 Chemical composition:

| Alloy | % | Cr | Ni | Co | W | C | Fe | Mn | Si | P | S |

|

HY L605 |

MIN |

19.0 |

9.0 |

- |

14.0 |

0.05 |

- |

1.0 |

- |

- |

- |

|

MAX |

21.0 |

11.0 |

Balance |

16.0 |

0.15 |

3.0 |

2.0 |

0.4 |

0.04 |

0.03 |

HY L605 Physical properties:

| Density | 9.27 g/cm3 |

| Melting point | 1330℃-1410 ℃ |

HY L605 sheet mechanical properties in the room temperature:

| Alloy Status | Tensile strength Rm N/mm² |

Yield strengthRP0.2 N/mm² | Elongation A5 % |

| Solution Treatment | 980 | 460 | 50 |

HY L605 Applications Fileds:

HY L-605 is useful in gas turbine applications such as rings, blades and combustion chamber parts (sheet fabrications) and can also can be used in industrial furnace applications such as muffles or liners in high temperature kilns.

HY L605 also used in the hot sections of aircrafts, parts for gas turbine engines, bearings, springs, and heart valve.

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

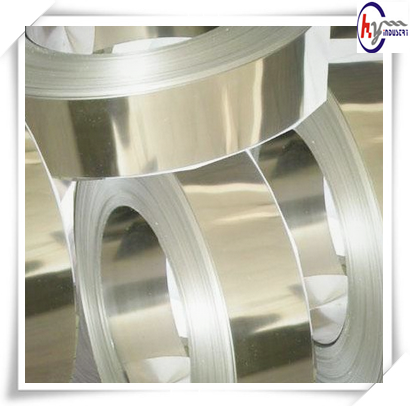

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

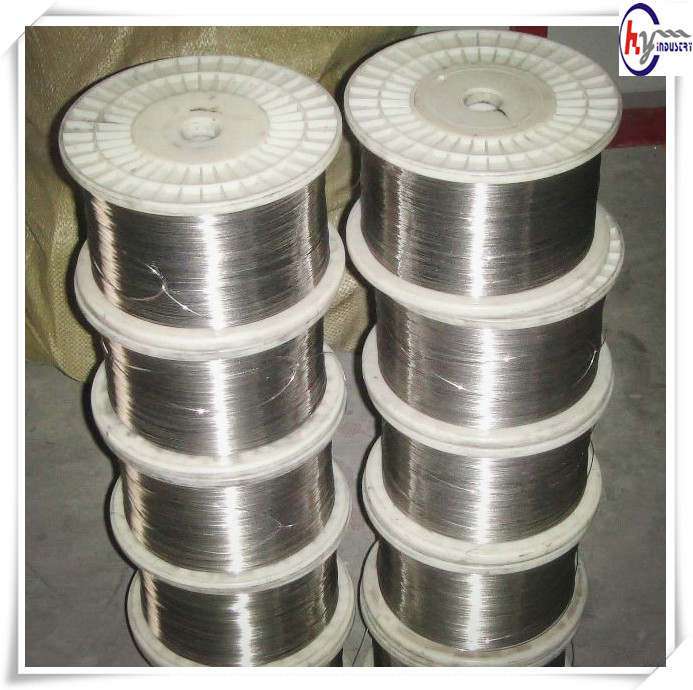

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

Check out additional TIG Welding Video clips from Weld.com:

http://www.weld.com/index.php/Mr-Tig-Blog/

Subscribe on YouTube and Never ever Miss a Video!

http://www.youtube.com/channel/UCM0kHJXSHR1k1wtLuliKmHg?sub_confirmation=one

Pay a visit to the Welding Discussion board to Carry on the Dialogue and Compete in Month to month Contests!

http://www.weld.com/index.php/Weekend-Warrior-Welding-Discussion board/groups.html

Fb: https://www.fb.com/WeldDotCom

Twitter: https://twitter.com/WeldDotCom

—————————————————————————–

Weld.com welding films are a collection of welding displays that are loaded with welding strategies, tricks and hints that will support you drop that perfect bead each individual time! Whether you are making an attempt to become far better in the locations of TIG Welding, MIG Welding, Adhere Welding or Slicing Weld.com has what you will need. All films are shot from “guiding the hood” so you can get the welders standpoint. In addition to exhibiting you how to weld, many periods we will clearly show you popular issues and how to steer clear of them.

New episodes each individual Friday!

Early launch on the discussion board!

High successful HRSA turbine blade roughing on Starrag LX 051

- Materials technical specs: Nimonic 80A, NiCr20TiAl (2.4952)

- MMR: sixteen.nine cm3/min