New Delivery for Titanium alloy 6Al-4V ELI UNS R56401 to Austria Factories

In the past few years, our company absorbed and digested advanced technologies both at home and abroad. Meanwhile, our company staffs a team of experts devoted to the development of New Delivery for Titanium alloy 6Al-4V ELI UNS R56401 to Austria Factories, winning customers' trust is the gold key to our success! If you are interested in our products, please feel free to visit our web site or contact us.

HY Titanium 6-4 ELI Material grades and equivalents

6-4 ELI Titanium, 6-4 ELI, UNS R56401

Introduction

Low interstitial version of HY Titanium 6-4 ELI, for maximum toughness. Preferred for marine and cryogenic applications. This grade is normally used in the annealed condition. HY Titanium 6-4 ELI is the preferred choice for the medical implant field.

Stress relief 900-1200°F 1 to 4 hours, air cool. Duplex anneal, bar and forgings: Solution anneal 50-100°F below the beta transus, hold 1 hour minimum, air cool. Then reheat within the range 1300-1400°F, hold 1 hour minimum, air cool. Stress – relief annealing is performed after welding.

Chemistry Composition

|

|

Al |

V |

Fe |

O |

C |

N |

H |

Y |

Others, |

Others, |

Ti |

|

MIN |

5.5 |

3.5 |

– |

– |

– |

– |

– |

– |

– |

– |

– |

|

MAX |

6.5 |

4.5 |

0.25 |

0.13 |

0.08 |

0.03 |

0.0125 |

0.005 |

0.1 |

0.4 |

Balance |

Features

- Resistant to bodily fluids

- Resistant to a variety of corrosive environments

- Freedom from chloride stress corrosion cracking

- Good strength and toughness over a wide temperature range

- High resistance to erosion corrosion and corrosion fatigue

- Useful resistance to dry chlorine, fluorine, hydrogen chloride and hydrogen fluoride gases

Applications

- Medical and dental implants

- Cryogenics

- Aerospace

- Chemical processing

Physical Properties

Density: 0.160 lb/in3

Melting Range: 2370 – 2460°F

Beta Transus: 91790+25°F

Minimum Tensile Properties, AMS 4919, Duplex Annealed

|

Temperature, °F |

68-212 |

68-600 |

68-1000 |

68-1200 |

68-1500 |

|

Coefficient* of Thermal Expansion, in/in°F x 10-6 |

9.18 |

9.54 |

10.08 |

10.44 |

10.8 |

Mechanical Properties

Typical hardness Rockwell: C 30-34 Specific minimums, AMS 4931, bar and forging

Representative Tensile Properties, Sheet

|

Diameter, in |

< 3.0 |

< 3.0 < 4.0 |

< 4.0) < 6.0 |

|

Tensile Strength, ksi |

125 |

123 |

120 |

|

0.2 % Yield Strength, ksi |

115 |

110 |

110 |

|

Elongation, % *L (**ST) |

10 (8) |

10 (8) |

8 (8) |

|

Reduction of Area, % *L (**ST) |

25 (–) |

20 (15) |

15 (15) |

* Longitudinal ** Short Transverse

Typical Elevated temperature Properties

|

Temperature, °F |

93 (200) |

149 (300) |

204 (400) |

260 (500) |

|

Ultimate Tensile Strength, ksi |

843.3 (121) |

772.2 (112) |

723.9 (105) |

657.7 (98) |

|

0.2 % Yield Strength, ksi |

710.2 (103) |

641.2 (93) |

586.1 (85) |

531.0 (77) |

|

Elongation, % |

13 |

15 |

16 |

16 |

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

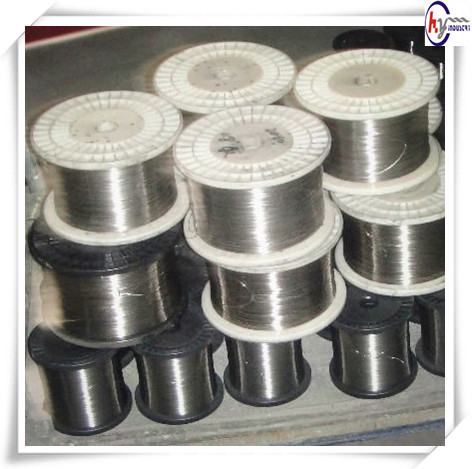

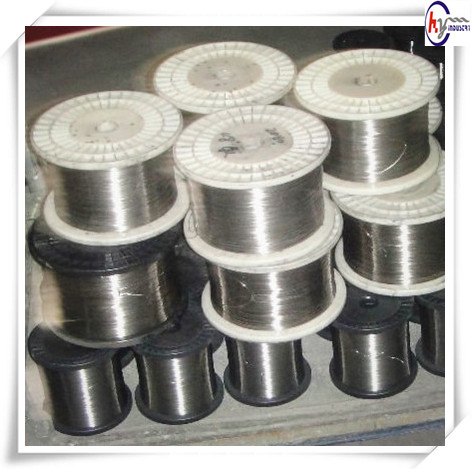

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

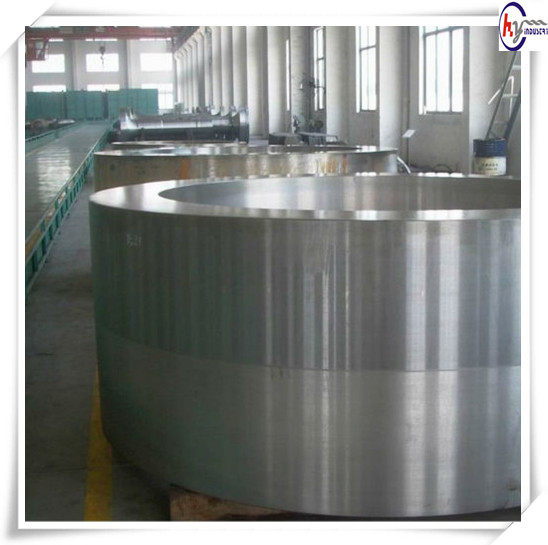

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

Visit my site for additional Recommendations, Films, Do it yourself assignments and additional:

http://www.mjlorton.com/

—————————–Click “Display additional”—————————————

A information on making use of the correct applications to crimp connectors, strip wire and implement warmth shrink.

You should guidance my information generation by making use of my Amazon Retail store:

http://astore.amazon.com/m0711-twenty

Purchase these applications and connectors below: http://astore.amazon.com/m0711-twenty?node=ten&site=one

——————— Click “Display additional” ——————————-

My site and forum:- http://www.mjlorton.com

Donations and contributions:- http://www.mjlorton.com

My techie channel MJLorton – Solar Power and Digital Measurement Products – http://www.youtube.com/MJLorton

My Techie Amazon Retail store: http://astore.amazon.com/m0711-twenty

My other channel VBlogMag – For nearly any matter beneath the sun! – http://www.youtube.com/VBlogMag

My VBlogMag Amazon Retail store: http://astore.amazon.com/vblogmag-twenty

———————————————————————–

=================================================

Online video sponsor, Pass Ltd – their internet websites:

http://www.tester.co.united kingdom/?cmid=QmhzQjcxYjVlc1E9&afid=bFcwbzliNzVDc289&ats=K2EyUjZNTDh3UTA9 – Examination Products and Examination-meter suppliers and

http://www.calibrate.co.united kingdom/?cmid=QmhzQjcxYjVlc1E9&afid=bFcwbzliNzVDc289&ats=S3Yxd2tOMjVISzA9 – Calibration and support of exam tools

=================================================

Additional dialogue and link to NASA information below:

http://mjlorton.com/forum/index.php?matter=244.

In this online video:

* Deciding upon the correct wire gauge (AWG – American Wire Gauge) for the crimp connector.

* Employing the correct applications to strip the insulation from the wire.

* The correct way to insert the wire into the crimp connector

* Employing the correct crimp applications to crimp the connector

* How to implement warmth shrink accurately to the wire and crimp connector.

Discovery and Science Channel’s How It truly is Designed Alloy Wheels episode.

All copyrights go to their respective homeowners.