Nickel Alloy Inconel 718 UNS N07718

HY 718 Material grades and equivalents

Inconel 718 / GB GH4169 / UNS N07718 / SEW VDIUV W.Nr.2.4668 NiCr19Fe19Nb5Mo3 / BS NA 51 / AFNOR NC19FeNb

HY 718 Chemical composition

|

Alloy |

% |

Ni |

Cr |

Fe |

Mo |

Nb |

Co |

C |

Mn |

Si |

S |

Cu |

Al |

Ti |

|

718 |

Min. |

50 |

17 |

balance |

2.8 |

4.75 |

0.2 |

0.7 |

||||||

|

Max. |

55 |

21 |

3.3 |

5.5 |

1 |

0.08 |

0.35 |

0.35 |

0.01 |

0.3 |

0.8 |

1.15 |

HY 718 Physical properties

|

Density |

8.2 g/cm³ |

|

Melting point |

1260-1340 ℃ |

HY 718 Alloy minimum mechanical properties in the roomtemperature

|

Alloy |

Tensile strength |

Yield strength |

Elongation |

Brinell hardness |

|

Solution treatment |

965 |

550 |

30 |

≤363 |

718 Characteristic as below:

1.workability

2.High tensile strength,endurance strength,creep strength and rupture strength at 700℃.

3.High inoxidability at1000℃.

4.Steady mechanical performance in the low temperature.

5.Good welding performance.

HY 718 Metallurgical structure

718alloy is Austenitic structure, precipitation hardening generate “γ” made it excellent mechanical performance. G rain boundary generate “δ” made it the best plasticity in the heat treatment.

HY 718 Corrosion resistance

718 alloy with extremely resistance to stress corrosion cracking and pitting ability in high temperature or low temperature environments, especially the inoxidability in the high temperature.

HY 718 Application field:

The elevated temperature strength, excellent corrosion resistance and workability at 700℃ properties made it use in a wide range of high requirement environments.

1.Steam turbine

2.Liquid-fuel rocket

3.Cryogenic engineering

4.Acid environment

5.Nuclear engineering

Specifications

|

Sheet/plate |

AMS 5599/AMS 5879/ASME SB-443 Gr. 1/ASTM B-443 Gr. 1 |

|

Bar/Forging |

AMS 5666/ASME SB-446 Gr. 1/ASTM B-446 Gr. 1 |

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

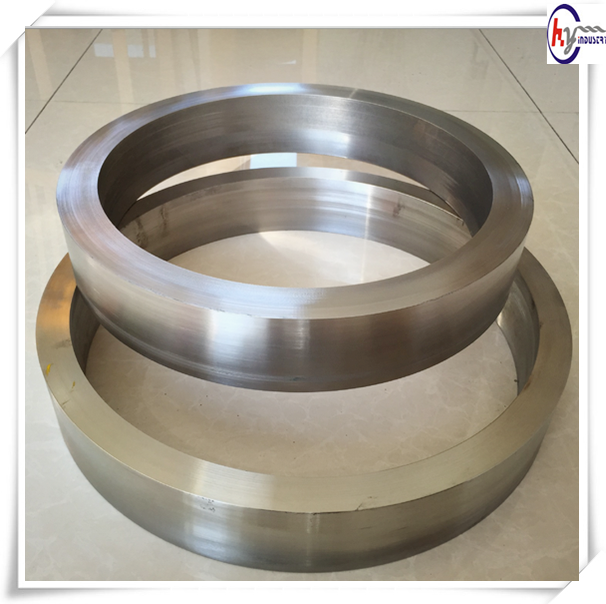

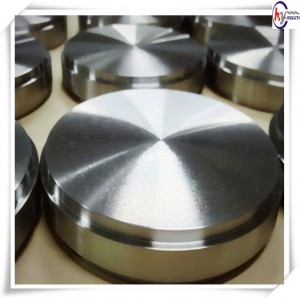

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |