OEM Manufacturer Titanium alloy 6Al-4V STA UNS R56400 to New Zealand Factory

We keep improving and perfecting our products and service. At the same time, we work actively to do research and development for OEM Manufacturer Titanium alloy 6Al-4V STA UNS R56400 to New Zealand Factory, we are looking forward to even greater cooperation with overseas customers based on mutual benefits. Please feel free to contact us for more detail

HY Titanium 6-4 STA Material grades and equivalents

6-4 STA Titanium, 6-4 STA, Ti 6-4 STA, UNS R56400

Introduction

HY Titanium 6-4 STA (Solution Treated and Aged) is a modified version of Ti 6Al-4V. It is heat treated for high strength in sections under 4″ thick. Ti-6Al-4V has excellent hardenability in sections up to 1″ thick with strengths as high as 165 ksi.

For maximum strength: solution-treated and aged (STA) condition is: For sheet, 1675-1725°F 5 to 25 minutes, water quench. Age 975°F 4 to 6 hours, air cool. For bars and forgings, 1675-1725°F 1 hour, water quench. Age 975-1025°F 4 to 8 hours, air cool.

HY Titanium 6-4 STA is resistant to general corrosion but may be quickly attacked by environments that cause breakdown of the protective oxide. These include hydrofluoric (HF), hydrochloric (HCl), sulfuric and phosphoric acids. Inhibitors may help for the last three but not for HF. Ti 6Al-4V STA resists attack by pure hydrocarbons, and most chlorinated and fluorinated hydrocarbons (provided water has not caused formation of small amounts of HCl and HF).

Chemistry Composition

|

|

Al |

V |

C |

N |

O |

H |

Fe |

Y |

Others, |

Others, |

Ti |

|

MIN |

5.5 |

3.5 |

– |

– |

– |

– |

– |

– |

– |

– |

– |

|

MAX |

6.75 |

4.5 |

0.08 |

0.05 |

0.2 |

0.0125 |

0.3 |

0.005 |

0.1 |

0.4 |

Balance |

Features

- High strength to 750°F

- Excellent general corrosion resistance

- High strength-to-weight ratio

Applications

- Aerospace, turbine engine and airframe applications

- Fasteners

- Medical and dental implants

- High performance Automotive

Physical Properties

Density: 0.160 lb/inch3

Melting Range: 2920 – 3020°F

Beta Transus: 1825± 25°F

|

Temperature, °F |

70 |

200 |

400 |

600 |

|

Coefficient of Thermal Expansion, in/in°F x 10-6 |

- |

5.3 |

5.4 |

5.5 |

|

Thermal Conductivity, |

4.0 |

4.3 |

5.2 |

6.1 |

|

Modulus of Elasticity, |

16.7 |

16.0 |

15.0 |

14.0 |

Mechanical Properties

Specified, STA sheet & plate

|

Tensile Strength, ksi |

0.2% Yield Strength, ksi |

Elongation in 2″, % |

|

170 |

160 |

10 |

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

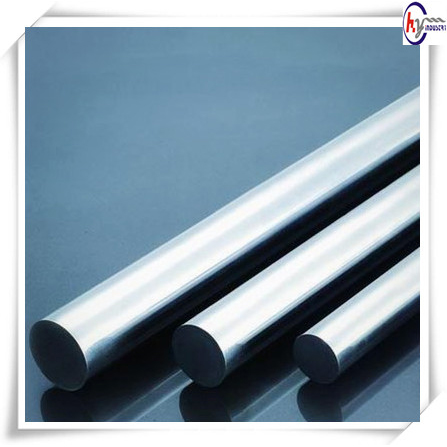

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

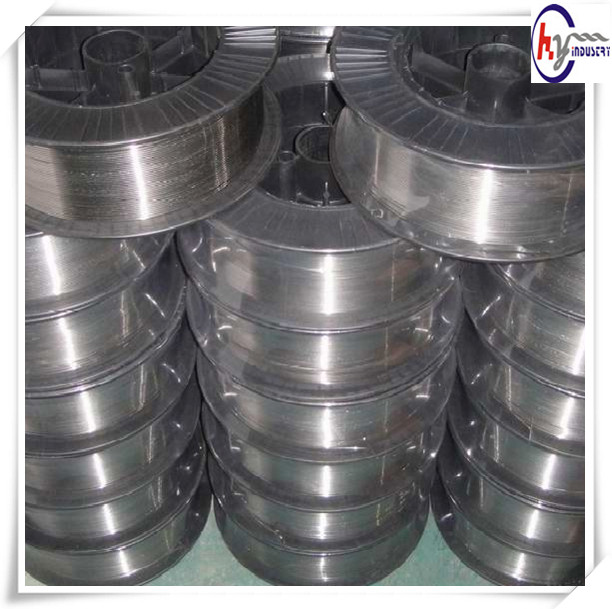

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

» Metal Tubes India is a GOVT. OF INDIA Acknowledged STAR EXPORT Dwelling & PED Accredited Maker

» Metal Tubes India is winner of All India Award for export excellence for 6 Consecutive Many years

» Metal Tubes India is an ISO 9001,ISO 14001,OHSAS 18001 Accredited company, our international CRISIL Ranking is SE 2B

» Metal Tubes India is European Force Machines Directive PED-97/23/EC qualified company

Ni 72., Cr fifteen.5, Fe 8. Mn 1. C .fifteen Cu .5 Si .5 S .015

Significant Efficiency Alloys stocks and produces this grade in the adhering to forms: Bar, wire, sheet, plate, coil, fasteners and forgings. Ask for quote on this grade.

Alloy 600 is a nickel-chromium alloy built for use from cryogenic to elevated temperatures in the selection of 2000 deg F(1093 deg C). The superior nickel material of the alloy allows it to retain substantial resistance less than lessening conditions and makes it resistant to corrosion by a range of natural and inorganic compounds. The nickel material gives it exceptional resistance to chloride-ion pressure-corrosion cracking and also offers exceptional resistance to alkaline options.

Inconel 600 Tube

ASME SB-163 ASME SB-516 ASME SB751 AMS 5580

UNS N06600 also offered in numerous forms like cap, elbow, erw pipes, fasteners, fittings, flange, plate, reducer, spherical bar, seamless pipes, sheet, tee and tube at industrial charge.

+ for extra info & specification about Inconel 600 remember to check out

http://www.steeltubesindia.internet/

Turning insert brochures are obtainable for obtain at http://www.mitsubishicarbide.com/mmus/en/products/catalog/turning.html

Mitsubishi offers particular J-Series breakers and micro-grain grades for turning hard to minimize supplies. Mitsubishi breakers for warmth resistant alloys include the FJ (mild slicing), MJ (medium slicing) and GJ (medium to semi-weighty slicing). The presenting is concluded with the addition of the twin rake MS (medium slicing) breaker and spherical RCMX insert also for medium slicing. FJ and MJ collection insert are obtainable in G Class tolerances for applications that need a sturdy sharp slicing edge. For Titanium and non-ferrous supplies, the polished FJ-P/MJ-P edition is obtainable.

The FJ’s sharp slicing geometry is obtainable in common .002, .004, .008 and .016″ software nose radius. Although the MS and MJ software nose radius begins at .016 and the GJ at .031″ and up. Our warmth resistant alloy breakers are obtainable in a vast range of micro-grain grades particularly design for this market place phase. Our micro-grain grades are obtainable non-coated or topped off with PVD/CVD coatings and edge preparations to suit to the insert software range.

Out there uncoated grades are: RT9005, RT9010, TF15 and Hti10.

Our Miracle Coating (Al, Ti)N PVD grades are: VP05RT, VP10RT and VP15TF.

CVD coated US905 is design to deliver unequalled dress in resistance in stable higher velocity applications. The close microstructure of US905 CVD coatings limits insert flank and deal with dress in at higher speeds when in contrast to other merchandise. US905 has the best hardness cemented carbide substrate appropriate for CVD Coating.

To see all Mitsubishi Cutting Device products channels on YouTube, comply with url:

http://www.youtube.com/user/mitsubishicarbide/video clips?view=one

Or

Go to 1 of our products precise channels below:

The Cutting Edge: http://www.youtube.com/playlist?list=PL1CEA67C978F3029D&feature=view_all

Turning & Dull Channel: http://www.youtube.com/playlist?list=PL0D406ECCFFF53995&feature=view_all

Milling Channel: http://www.youtube.com/playlist?list=PL648BF1B051AE20F0&feature=view_all

Drilling Channel: http://www.youtube.com/playlist?list=PL6960075BD195101A&feature=view_all

Grooving Channel: http://www.youtube.com/playlist?list=PL3AD4CC3127719A38&feature=view_all

Swiss Tooling Channel: http://www.youtube.com/playlist?list=PL0FBAAF2F0230343C&feature=view_all

CBN Channel: http://www.youtube.com/playlist?list=PLBB88F97F9A2B5376&feature=view_all

Strong Carbide Close Mill Channel: http://www.youtube.com/playlist?list=PL7A1549BEF477EDDB&feature=view_all

Mitsubishi Elements Usa – Cutting Applications, Social Media Websites:

Fb: http://www.facebook.com/MitsubishiMaterials.US.CuttingTools

Twitter: http://twitter.com/#!/MMUSCuttingTool

YouTube: http://www.youtube.com/user/mitsubishicarbide

Supplemental Means:

Encounter Mitsubishi Carbide’s Patented On the internet Catalog with downloadable CAD information http://www.mitsubishicarbide.internet/mmus/en/catalogue/index.html

Extra Mitsubishi Cutting Device Films can be discovered at http://www.mitsubishicarbide.com/mmus/en/products/online video/index.html

Issues remember to speak to:

Complex Guidance at one-800-486-2341

Or

E mail MarketingServices@mmus.com

Protected specialized inquires can be submitted to Mitsubishi Elements at https://www.mitsubishicarbide.com/mailform/mmus/en/literature/sort.html

Thank you for using the time to view this online video and remember to take a look at Mitsubishi Elements Usa at http://www.mmus.com