Professional High Quality Nickel Alloy Hastelloy C UNS N06003 Manufacturer in Curacao

We have a highly efficient team to deal with inquiries from customers. Our goal is "100% customer satisfaction by our product quality, price & our team service" and enjoy a good reputation among clients. With many factories, we can provide a wide range of Professional High Quality Nickel Alloy Hastelloy C UNS N06003 Manufacturer in Curacao, we have built a reliable reputation among many customers. Quality&customer first are always our constant pursuit. We spare no efforts to make better products. Look forward to long-term cooperation and mutual benefits!

HY HC Chemical composition

| Alloy |

% |

Ni |

Cr |

Mo |

Fe |

W |

Co |

C |

Mn |

Si |

V |

P |

S |

|

C |

Min. |

balance |

14.5 |

15 |

4 |

3 |

|||||||

|

Max. |

16.5 |

17 |

7 |

4.5 |

2.5 |

0.08 |

1 |

1 |

0.35 |

0.04 |

0.03 |

||

|

C22 |

Min. |

balance |

20 |

12.5 |

2 |

2.5 |

|||||||

|

Max. |

22.5 |

14.5 |

6 |

3.5 |

2.5 |

0.02 |

0.5 |

0.08 |

0.35 |

0.02 |

0.02 |

HY HC Physical properties

|

Density |

8.9 g/cm3 |

|

Melting point |

1325-1370 °C |

HY HC Alloy minimum mechanical properties in the room temperature

| Alloy state |

Tensile strength Rm N/mm2 |

Yield strength R P 0.2 N/mm2 |

Elongation A 5 % |

|

Hastelloy C22 |

690 |

283 |

40 |

Characteristic as below

HY HC is a omnipotent of nickel, chromium and molybdenum mixed alloy, with better corrosion resistance performance than other alloys, for example, Hastelloy C276 alloy, C4 alloy and 625 alloy. HY HC have a good resistance performance to pitting, crevice corrosion and stress corrosion cracking, have excellent inoxidability water medium performance, including the wet-chlorine, nitric acid or oxidizing acid mixed acid with chloride ion. Meantime, HY HC possesses perfect resistance to reduction and oxidation of processing enviroments, then it can be used in some complicated environment or with many different manufacture target factory depend on the omnipotent performance. HY HC possess prominent resistance performance to different chemical environments, including strong oxidizing matter, such as iron chloride, copper chloride, chlorine, heat pollution liquid(organic and inorganic), formic acid, acetic acid, acetyl oxide, sea water and salting liquid and so on.

HY HC Metallurgical structure

HY HC is face-centered cubic lattice structure.

HY HC Corrosion resistance

HY HC alloy suit for many kinds of chemical process industry which contain the oxidizing medium and reductant. High molybdenum and chromium content make it can resist the chloride corrosion, and tungsten make this corrosion resistance better. HY HC is one of a few material that can resist the corrosion of moist chlorine, hypochlorite and chlorine dioxide, this alloyhave prominent corrosion resistanceto high concentration chlorate( iron chloride and copper chloride)

HY HC Application field

HY HC is widely used in the chemical field and petrifaction field, such as the element of chloride organic and catalyze system. This material especially suit for high temperature environments, impure inorganic acid and organic acid (such as formic acid and acetic acid), sea-water corrosion environments.

HY HC Other application field

1. Acetic acid/acetyl oxide

2.Acid dipping

3.Cellophane paper manufactures

4.Chloride system

5. Complicated mixed acid

6. Electrogalvanizing groove roller

7.Expansion bellows

8.Flue gas washer system

9.Geothermal well

10.Fluorine hydride furnace cleaner

11.Incineration cleaner system

12. Nuclear fuel regeneration

13. Pesticide manufacture

14.Phosphoric acid manufacture

15.Acid cleaning system

16.Plate heat exchanger

17. Selectivity filter system

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

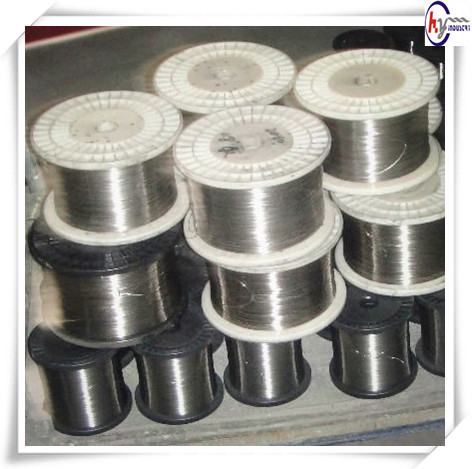

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

Turning insert brochures are obtainable for obtain at http://www.mitsubishicarbide.com/mmus/en/products/catalog/turning.html

Mitsubishi offers particular J-Series breakers and micro-grain grades for turning hard to minimize supplies. Mitsubishi breakers for warmth resistant alloys include the FJ (mild slicing), MJ (medium slicing) and GJ (medium to semi-weighty slicing). The presenting is concluded with the addition of the twin rake MS (medium slicing) breaker and spherical RCMX insert also for medium slicing. FJ and MJ collection insert are obtainable in G Class tolerances for applications that need a sturdy sharp slicing edge. For Titanium and non-ferrous supplies, the polished FJ-P/MJ-P edition is obtainable.

The FJ’s sharp slicing geometry is obtainable in common .002, .004, .008 and .016″ software nose radius. Although the MS and MJ software nose radius begins at .016 and the GJ at .031″ and up. Our warmth resistant alloy breakers are obtainable in a vast range of micro-grain grades particularly design for this market place phase. Our micro-grain grades are obtainable non-coated or topped off with PVD/CVD coatings and edge preparations to suit to the insert software range.

Out there uncoated grades are: RT9005, RT9010, TF15 and Hti10.

Our Miracle Coating (Al, Ti)N PVD grades are: VP05RT, VP10RT and VP15TF.

CVD coated US905 is design to deliver unequalled dress in resistance in stable higher velocity applications. The close microstructure of US905 CVD coatings limits insert flank and deal with dress in at higher speeds when in contrast to other merchandise. US905 has the best hardness cemented carbide substrate appropriate for CVD Coating.

To see all Mitsubishi Cutting Device products channels on YouTube, comply with url:

http://www.youtube.com/user/mitsubishicarbide/video clips?view=one

Or

Go to 1 of our products precise channels below:

The Cutting Edge: http://www.youtube.com/playlist?list=PL1CEA67C978F3029D&feature=view_all

Turning & Dull Channel: http://www.youtube.com/playlist?list=PL0D406ECCFFF53995&feature=view_all

Milling Channel: http://www.youtube.com/playlist?list=PL648BF1B051AE20F0&feature=view_all

Drilling Channel: http://www.youtube.com/playlist?list=PL6960075BD195101A&feature=view_all

Grooving Channel: http://www.youtube.com/playlist?list=PL3AD4CC3127719A38&feature=view_all

Swiss Tooling Channel: http://www.youtube.com/playlist?list=PL0FBAAF2F0230343C&feature=view_all

CBN Channel: http://www.youtube.com/playlist?list=PLBB88F97F9A2B5376&feature=view_all

Strong Carbide Close Mill Channel: http://www.youtube.com/playlist?list=PL7A1549BEF477EDDB&feature=view_all

Mitsubishi Elements Usa – Cutting Applications, Social Media Websites:

Fb: http://www.facebook.com/MitsubishiMaterials.US.CuttingTools

Twitter: http://twitter.com/#!/MMUSCuttingTool

YouTube: http://www.youtube.com/user/mitsubishicarbide

Supplemental Means:

Encounter Mitsubishi Carbide’s Patented On the internet Catalog with downloadable CAD information http://www.mitsubishicarbide.internet/mmus/en/catalogue/index.html

Extra Mitsubishi Cutting Device Films can be discovered at http://www.mitsubishicarbide.com/mmus/en/products/online video/index.html

Issues remember to speak to:

Complex Guidance at one-800-486-2341

Or

E mail MarketingServices@mmus.com

Protected specialized inquires can be submitted to Mitsubishi Elements at https://www.mitsubishicarbide.com/mailform/mmus/en/literature/sort.html

Thank you for using the time to view this online video and remember to take a look at Mitsubishi Elements Usa at http://www.mmus.com

Check out additional TIG Welding Video clips from Weld.com:

http://www.weld.com/index.php/Mr-Tig-Blog/

Subscribe on YouTube and Never ever Miss a Video!

http://www.youtube.com/channel/UCM0kHJXSHR1k1wtLuliKmHg?sub_confirmation=one

Pay a visit to the Welding Discussion board to Carry on the Dialogue and Compete in Month to month Contests!

http://www.weld.com/index.php/Weekend-Warrior-Welding-Discussion board/groups.html

Fb: https://www.fb.com/WeldDotCom

Twitter: https://twitter.com/WeldDotCom

—————————————————————————–

Weld.com welding films are a collection of welding displays that are loaded with welding strategies, tricks and hints that will support you drop that perfect bead each individual time! Whether you are making an attempt to become far better in the locations of TIG Welding, MIG Welding, Adhere Welding or Slicing Weld.com has what you will need. All films are shot from “guiding the hood” so you can get the welders standpoint. In addition to exhibiting you how to weld, many periods we will clearly show you popular issues and how to steer clear of them.

New episodes each individual Friday!

Early launch on the discussion board!