Quality Inspection for Nickel Alloy Incoloy 825 UNS N08825 for Malaysia Factory

With our excellent management, strong technical capability and strict quality control system, we continue to provide our clients with reliable quality, reasonable prices and excellent services. We aim at becoming one of your most reliable partners and earning your satisfaction for Quality Inspection for Nickel Alloy Incoloy 825 UNS N08825 for Malaysia Factory, If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

HY 825

Material grades and equivalents

Incoloy 825/GB NS1402/UNS N08825/SEW VDIUV W.Nr.2.4858 NiCr21Mo/BS NA16/AFNOR NC21FeDU

HY 825Chemical composition

|

Alloy |

% |

Ni |

Cr |

Fe |

C |

Mn |

Si |

Cu |

Mo |

Al |

Ti |

P |

S |

|

825 |

Min. |

38 |

19.5 |

balance |

1.5 |

2.5 |

1.0 |

0.6 |

|||||

|

Max. |

46 |

23.5 |

balance |

0.05 |

1 |

0.5 |

3 |

3.5 |

0.2 |

1.2 |

0.02 |

0.03 |

HY 825Physical properties

|

Density |

8.1 g/cm³ |

|

Melting point |

1370-1400°C |

HY 825Alloy mi nimum mechanical properties in the room temperature

|

Alloy state |

Tensile strength |

Yield strength |

Elongation |

Brinell hardness |

|

825 |

550 |

220 |

30 |

≤200 |

Characteristic as below

1. Good stress corrosion cracking resistance performance

2. Good resistance for pitting and crevice corrosion performance

3. Good anti-oxidation and non-oxidzing heat acid performance

4. Good mechanical performance in both room temperature and up to 550°C

5. Have the pressure vessel authenticate when manufacture temperature up to 450°C

HY 825Metallurgical structure

825 is the face-centered cubic lattice structure.

HY 825Corrosion resistance

825 is an all-purpose project alloy, have good corrosion resistance of the acid and alkali metal property in both oxidation and reduction environments. High nickel content made it with effective stress corrosion cracking resistance performance. 825 have excellent corrosion resistance in different kinds of media, such as sulfuric acid, phosphoric acid, nitric acid and organic acid, alkali metal such as sodium hydroxide, potassium hydroxide, and hydrochloric acid. A variety of media corrosion of nuclear-burning dissolver show 825 high integrated prpperty, like sulfuric acid, nitric acid and potassium hydroxide are all dealing in a same device.

HY 825Application field

825widely use in many kinds of industry field that the working temperature no more than 550°C.

HY 825Typical application field

1. Sulfuric acid factory usage for heating pipe, container, basket, chain and so on.

2. Cooling heat exchanger, marine product pipeline system and gas pipeline of acidic environment.

3. Heat exchanger, steam machine, washing, impregnation pipe, etc. for phosphoric acid produce

4. Oil refining in the air heat exchanger

5. Food project

6. Chemical process

7. Application of high pressure oxygen flam-retardant alloy

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

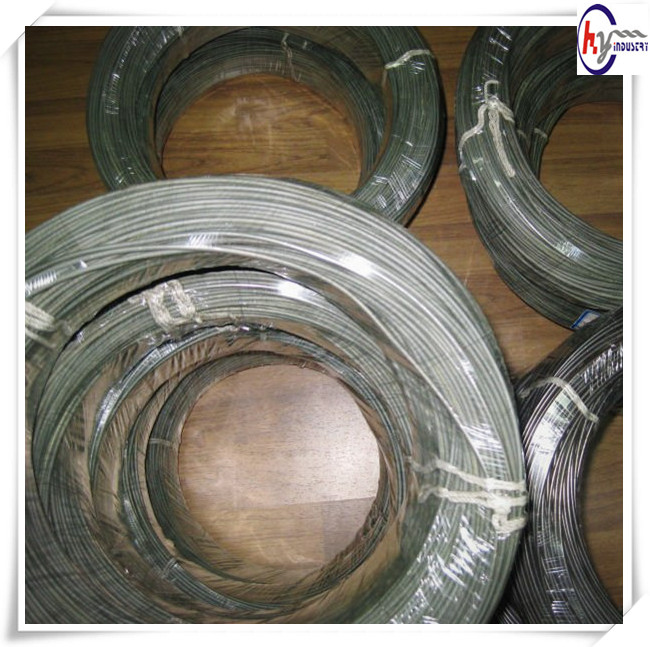

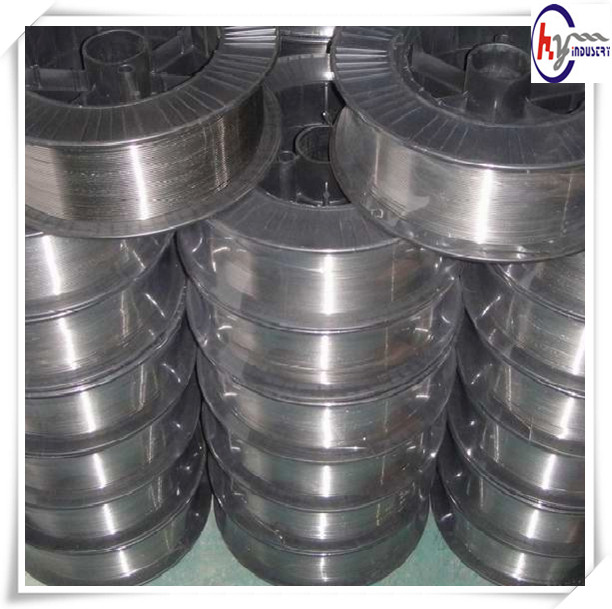

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

Riporto(placcatura)con filo Nimonic 80 dia. one.2 eseguito con inverter multiprocesso Weldtronic Synertech 8004 Digit in pulsato sinergico.

NB .Il lampeggio dell’arco è presente solo nella ripresa effettuata dalla fotocamera digitale usata probabilmente a causa di interferenza con l’intenso arco luminoso.

Details: belda1@tiscali.it

Check out additional TIG Welding Video clips from Weld.com:

http://www.weld.com/index.php/Mr-Tig-Blog/

Subscribe on YouTube and Never ever Miss a Video!

http://www.youtube.com/channel/UCM0kHJXSHR1k1wtLuliKmHg?sub_confirmation=one

Pay a visit to the Welding Discussion board to Carry on the Dialogue and Compete in Month to month Contests!

http://www.weld.com/index.php/Weekend-Warrior-Welding-Discussion board/groups.html

Fb: https://www.fb.com/WeldDotCom

Twitter: https://twitter.com/WeldDotCom

—————————————————————————–

Weld.com welding films are a collection of welding displays that are loaded with welding strategies, tricks and hints that will support you drop that perfect bead each individual time! Whether you are making an attempt to become far better in the locations of TIG Welding, MIG Welding, Adhere Welding or Slicing Weld.com has what you will need. All films are shot from “guiding the hood” so you can get the welders standpoint. In addition to exhibiting you how to weld, many periods we will clearly show you popular issues and how to steer clear of them.

New episodes each individual Friday!

Early launch on the discussion board!